A double-sided rolling device for thin-walled structures

A rolling device and thin-walled structure technology, which is applied in the field of rolling processing, can solve the problems of low rigidity, avoid deformation of workpieces, and improve quality integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

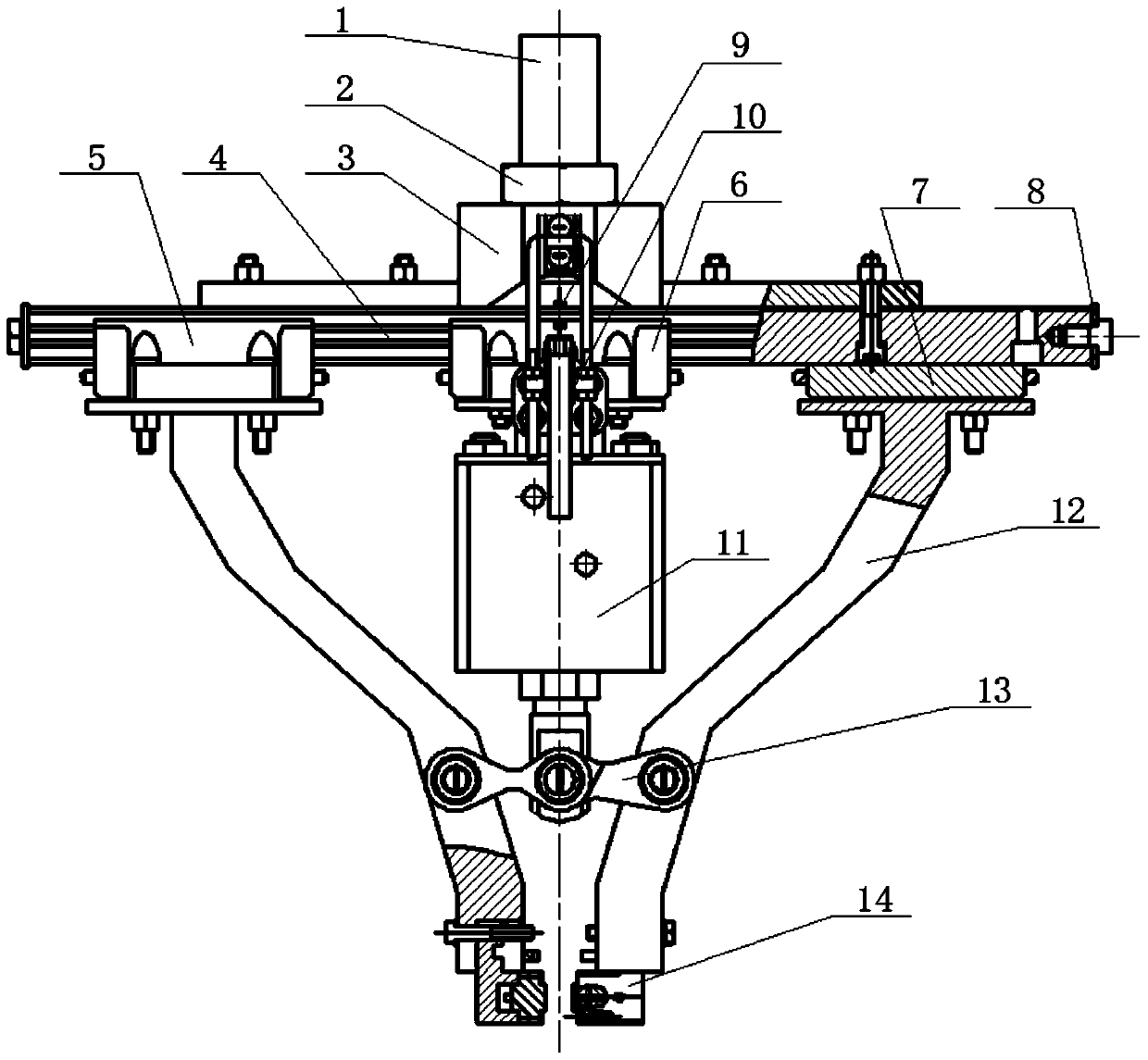

[0019] Such as figure 1 As shown, the double-sided rolling device for thin-walled structures of the present invention mainly includes a tool bar 1, a frame 3, a slide rail 4, a tool holder 12, a hydraulic cylinder 11 and a rolling head 14. The upper part of the frame 3 is threadedly connected with a tool bar 1 and is fastened by a fixing nut 2 screwed on the tool bar 1 to prevent the threaded connection from being loosened. The slide rail 4 is connected to the bottom of the rack 3 by bolts. The slide rail 4 has a left slider 5, a middle slider 6 and a right slider 7 in sequence. The middle slider 6 is located between the left slider 5 and the right slider 7, and is locked by bolts, eccentric wheels, etc. The tightening mechanism fixes the slider 6 in a proper position on the slide rail 4. Opening the locking mechanism allows the three sliders to slide freely in the slide rail 4, and the maximum displacement is limited by the retaining rings 8 installed at both ends of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com