A kind of preparation technology of ion conductive concrete

A technology of ionic conduction and preparation process, applied in the field of concrete, can solve problems such as the difficulty of uniform distribution of electrolyte solution, the influence of concrete mechanical properties, and electrochemical corrosion of electrode selection, so as to achieve low resistivity, improved overall mechanical properties, and improved electrical conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

[0031] The preparation process of a kind of ion-conductive concrete provided by the embodiment of the present invention is characterized in that: comprising the following steps:

[0032] (1) Preparation of concrete specimen: fix the metal electrode in the test mold; put cement and sand into the mixer and stir, then add aluminum powder to stir; put the mold into the mold and vibrate on the vibrating table until it is dense, and keep it in the vibration process. The relative position of the electrodes remains unchanged; the surface of the concrete is lightened, the bread is cut off after a static stop, and then the surface is lightened again;

[0033] (2) formwork removal and maintenance: remove formwork after the concrete in step (1) is finally set, and form ion-conductive concrete specimen after curing for 28 days;

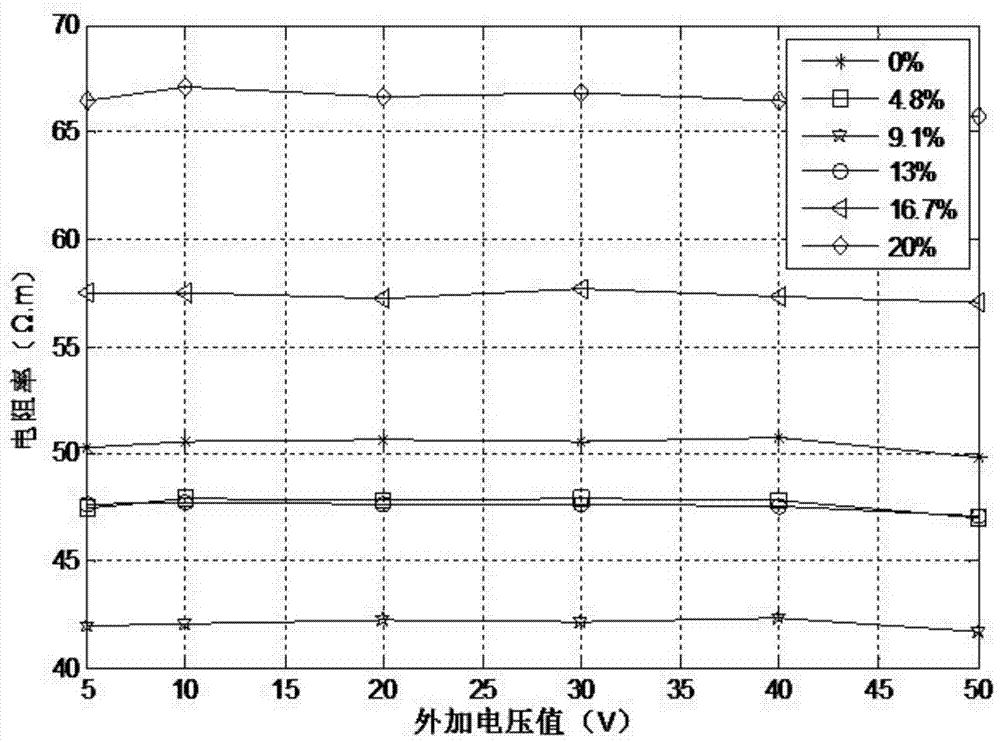

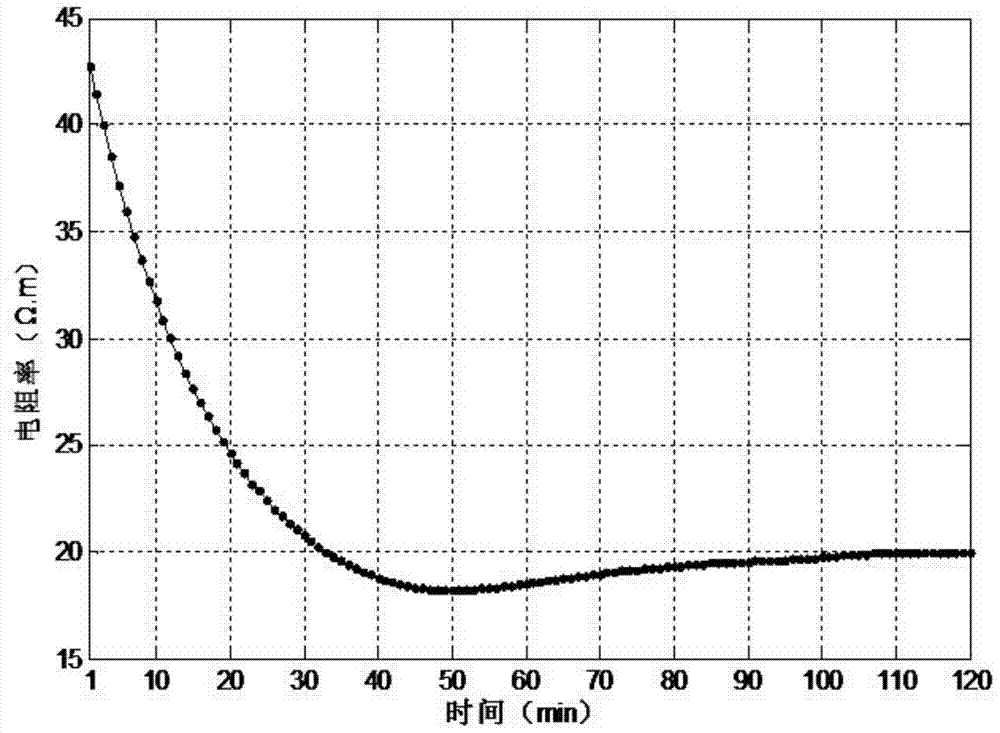

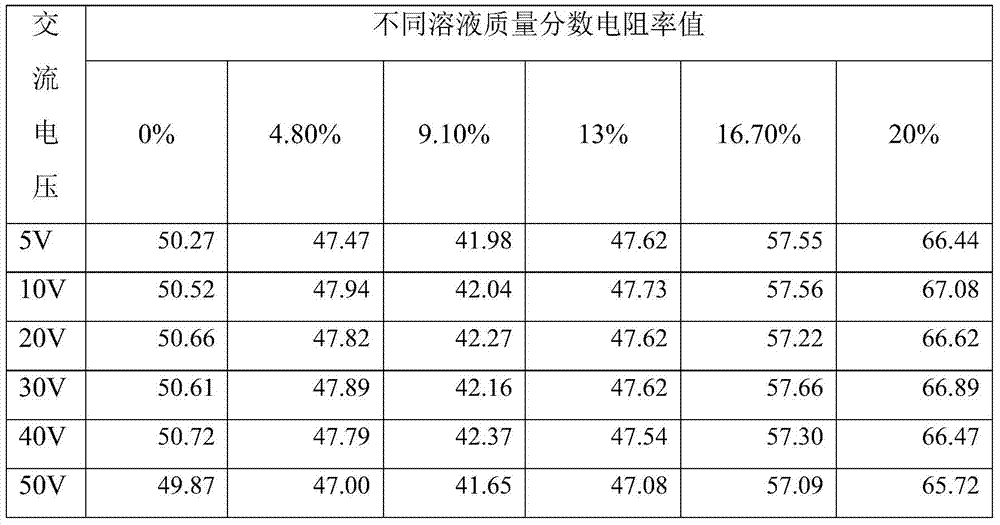

[0034] (3) Specimen penetration: the ion-conductive concrete spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com