Preparation device and backfilling method for flow-state cement soil

A technology for preparing equipment and cement soil, which is applied in filling, construction, and infrastructure engineering, etc., can solve the problems of large deformation of foundation pits, long construction period, and low degree of mechanization, so as to ensure the compactness of backfilling, solve the problems of small sites, and speed up The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

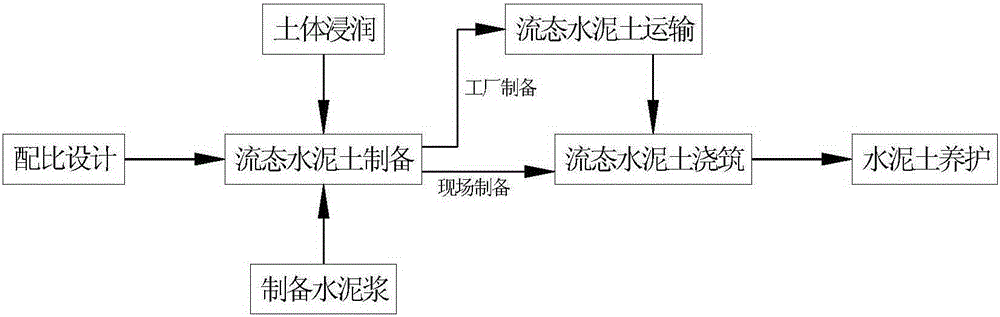

[0035] The invention provides a method of utilizing the fluidity and self-compacting properties of cement soil in wet construction to solve the problem of backfill soil transportation in narrow construction sites and the quality problems of backfill soil compaction in narrow spaces, so as to speed up the construction progress, save vertical waterproof protective layers, and improve Waterproof quality effect, realize green construction.

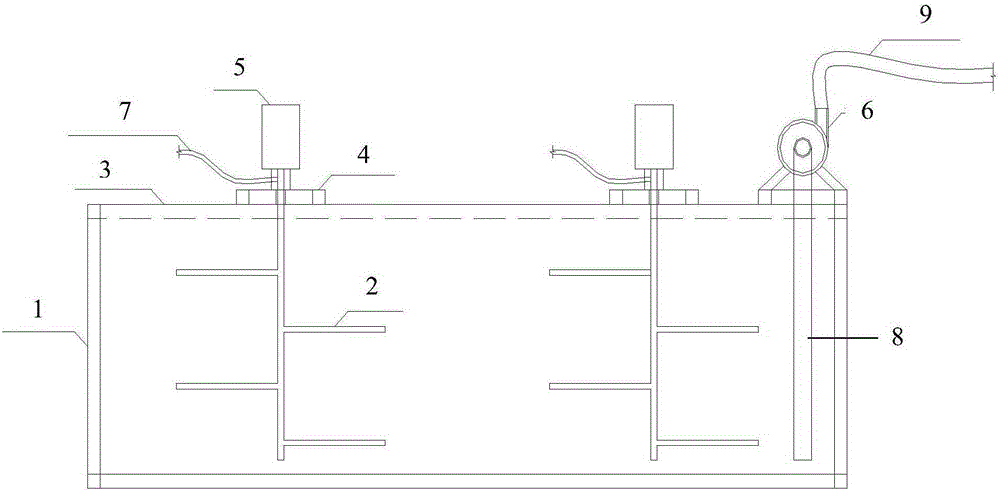

[0036] figure 1 It is a schematic diagram of a liquid cement soil preparation device according to the present invention. as the picture shows,

[0037] A preparation device for fluid cement soil is composed of a fluid cement soil preparation pool 1, a cement soil mixing and spraying drill bit 2, and a cement slurry making backstage (not shown).

[0038] In detail, the fluid cement-soil preparation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com