Engine cooling device

A cooling device and engine technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of poor cooling effect, disadvantage, lower oil temperature, etc., to achieve lower temperature, convenient disassembly, easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

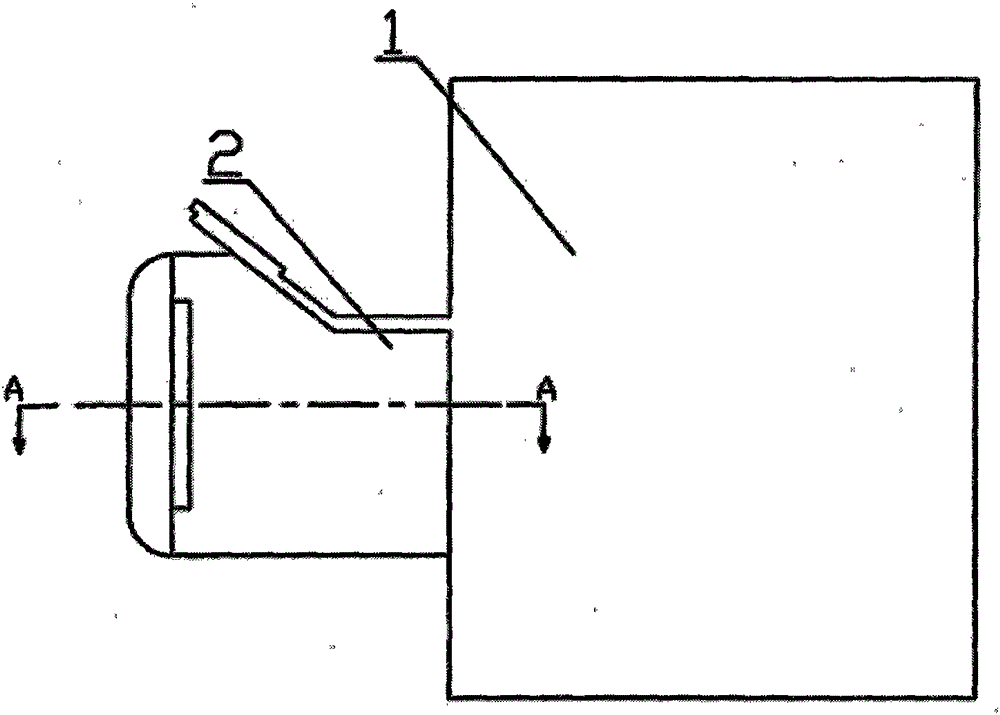

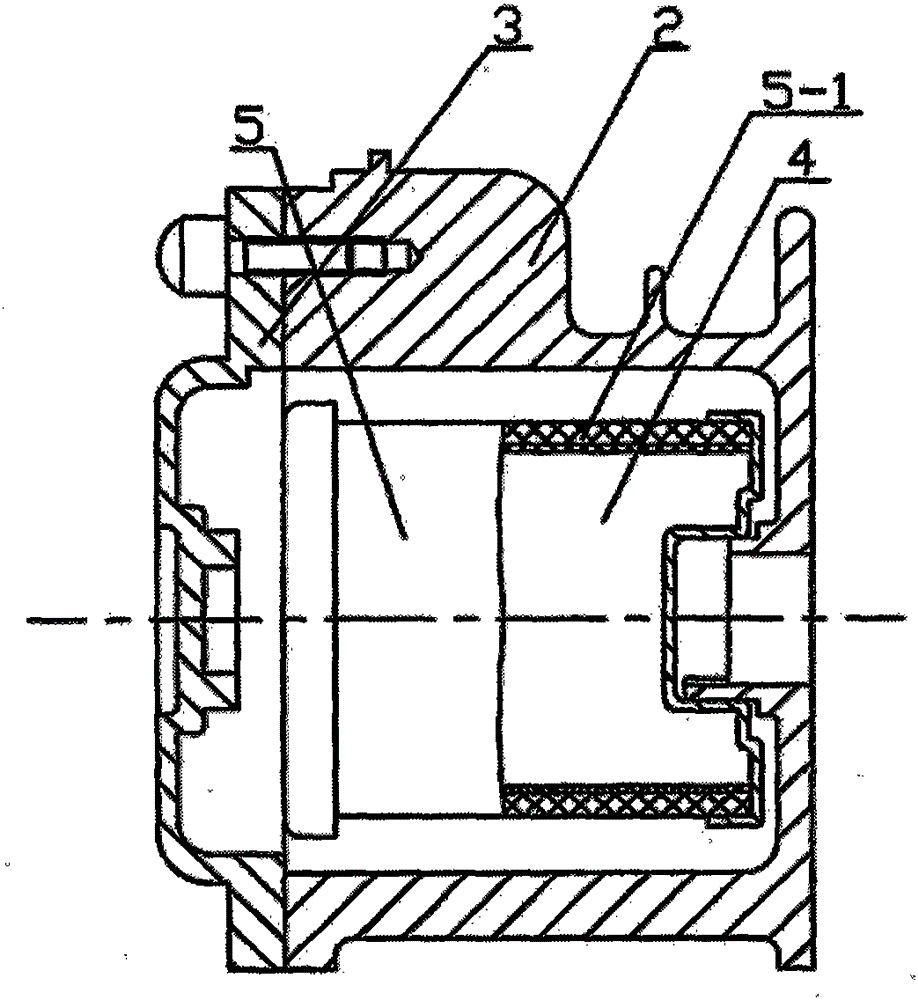

[0013] Example: such as figure 1 and figure 2 The engine cooling device shown includes a casing 1 and a crankshaft arranged on the casing 1, and also has an oil fine filter 5 for filtering the casing 1 oil, and a right side casing is fixedly installed on the casing on the right side of the casing 1. Cover 2, the other end of the right side cover 2 is fixedly connected to the organic filter cover 3, a cavity 4 is formed between the right side cover 2 and the machine filter cover 3, and the described engine oil fine filter is arranged in the described cavity 4, and the engine oil The fine filter 5 has a paper filter element assembly 5-1, and a compression spring that compresses the paper filter element assembly 5-1 is arranged in the machine filter cover 3, and the box body 1, the machine filter cover 3 and the right side cover 2 pass through the bolts Fixed connection.

[0014] The fine oil filter 5 is located at the front end of the casing. During the movement of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com