Direct-plug type energy absorption assembly of thin-walled tube

A technology of thin-walled tubes and energy-absorbing components, which is applied to elastic shock absorbers, bumpers, etc., can solve problems such as loss of bearing capacity of tubes, structural collapse, and flattening of cross-sections, so as to reduce the load uniformity coefficient and reduce local Effects of buckling and failure, increased load carrying capacity and specific energy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

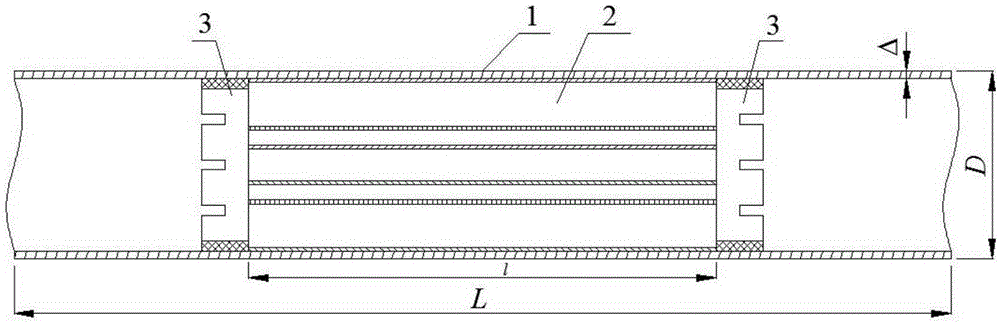

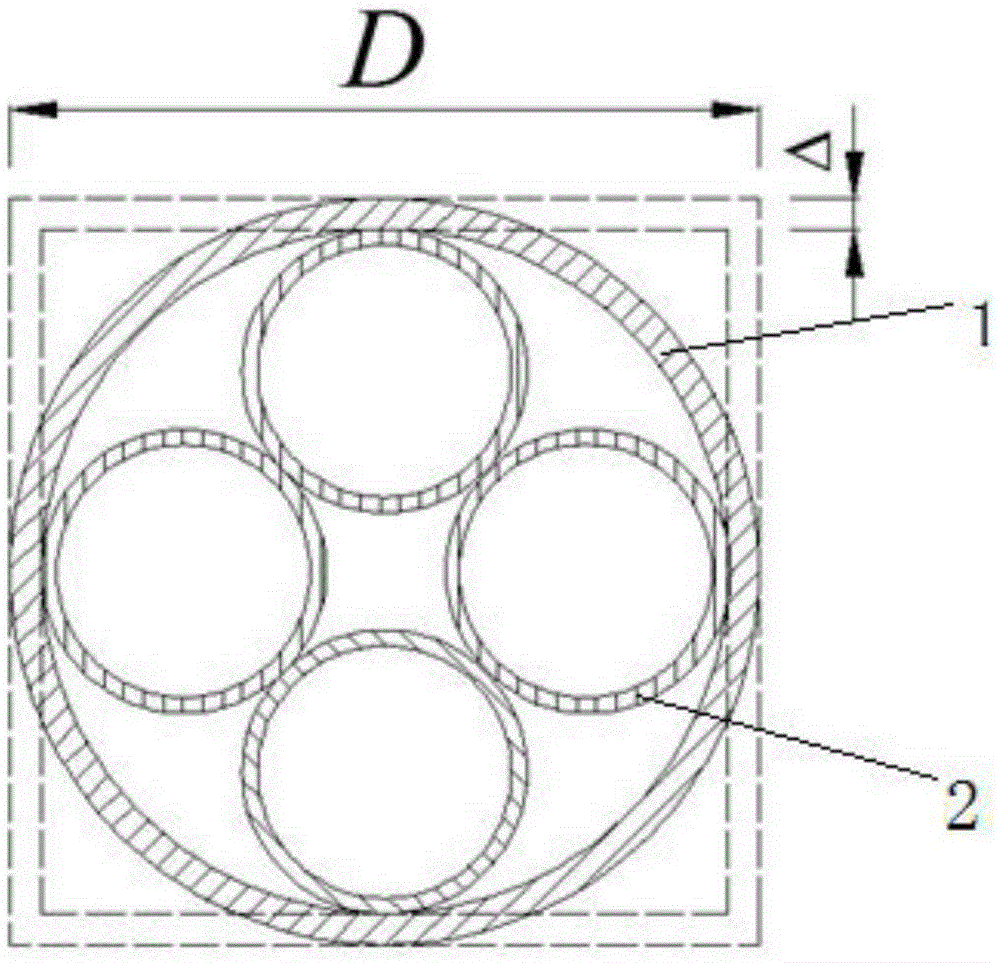

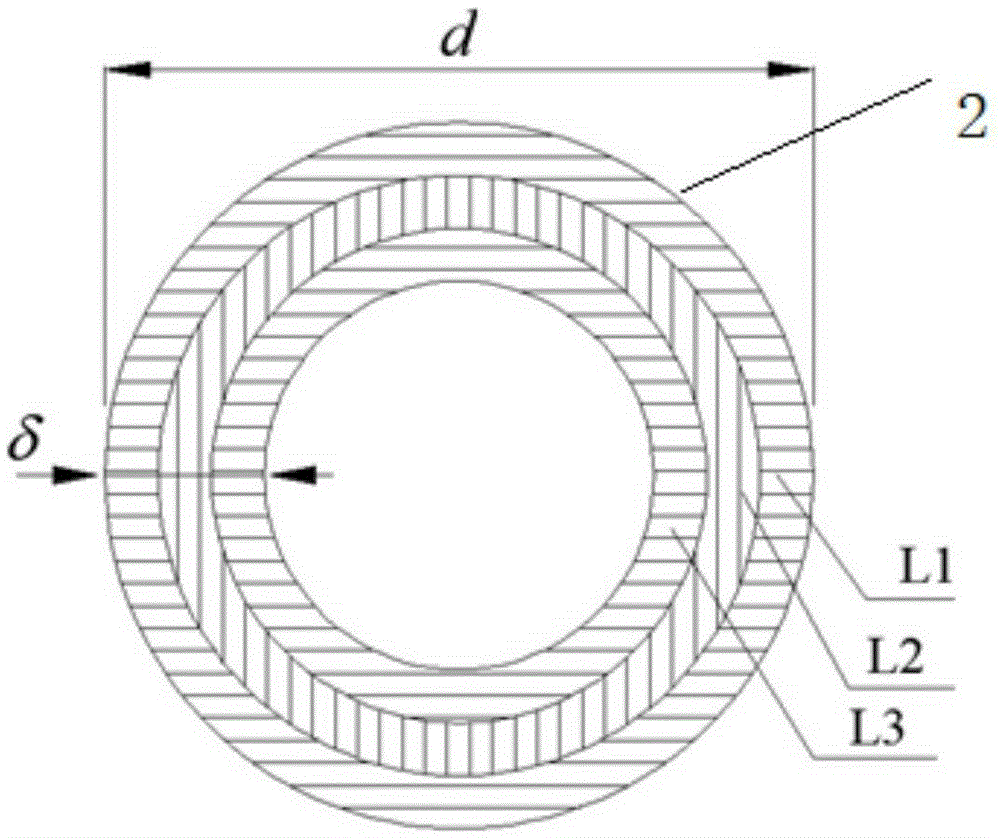

[0016] Such as figure 1 and figure 2 As shown, the energy-absorbing assembly of straight-plug thin-walled pipe fittings includes four energy-absorbing elements 2 and fixing elements 3, and the energy-absorbing elements 2 are multi-layer composite round pipes, such as image 3 As shown, the wall materials of the adjacent layers of the multilayer composite circular tube are orthogonal to each other; the two ends of the energy-absorbing element 2 are fixed on the fixing element 3, as Figure 4 As shown, the other side of the fixing element 3 is a petal-shaped opening, and the energy-absorbing element 2 and the fixing element 3 are installed in the thin-walled pipe 1 .

[0017] The energy-absorbing element 2 is placed in the thin-walled pipe fitting 1. The energy-absorbing element 2 is located near the impact load to absorb kinetic energy and reduce the flatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com