Electric generator iron loss test apparatus and experimental method

A technology of iron loss test and generator, applied in the direction of motor generator test, measurement device, measurement of electrical variables, etc., can solve the problems of generator stator damage, inconvenient test development, etc., to improve enthusiasm, intuitive test results, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and example the present invention will be further described:

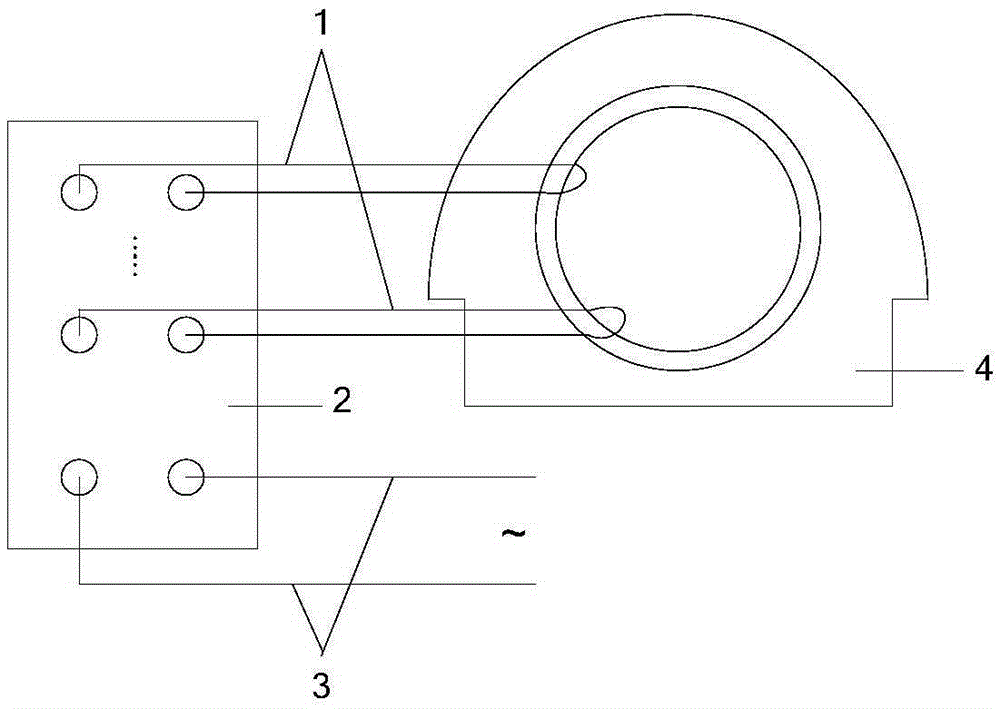

[0025] figure 1 Among them, a generator 4 iron loss test device, including a group test cable 11 and a 10kV switch cabinet 2 electrically connected to the group test cable 11, and a power cable 3 connected to the factory power;

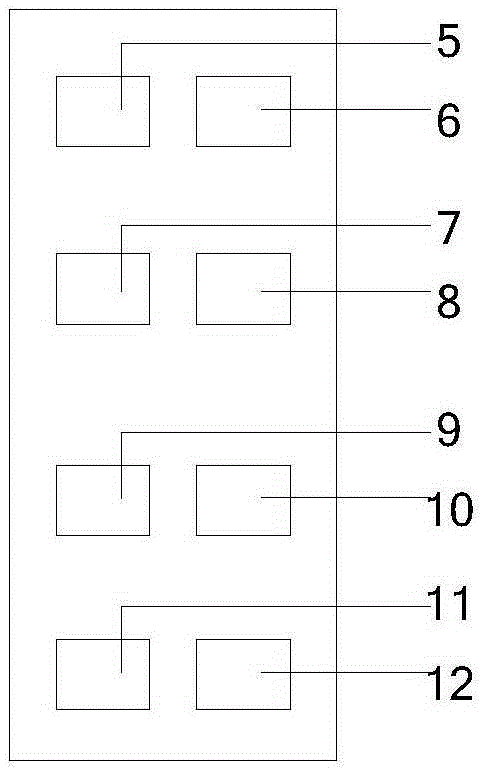

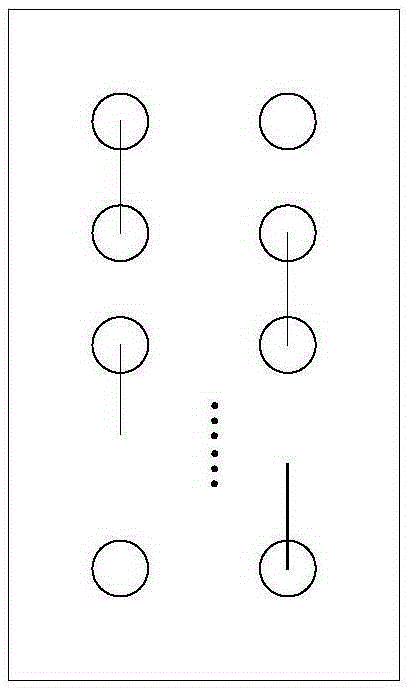

[0026] One end of the group test cable 1 is directly connected to the switch cabinet, and the other end is wound around the generator 4 iron core to set the number of turns and then connected to the switch cabinet. The switch cabinet is connected to the power supply through the power cable 3; the group test cable 1 includes several groups and test cables with different lengths; the group test cable 1 is a test cable that can pass a large current for a long time for the iron loss test of the generator 4;

[0027] In the test, the switchgear is connected to the 6kV utility power, and each test cable is connected to the switchgear after w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com