Continuous sterilization and repetition learning self-adaptive controller on the basis of characteristic model

A technology of adaptive controller and characteristic model, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve difficult production conditions, control parameters or fuzzy logic cannot be automatically adjusted, medium temperature at the ejector outlet Problems such as difficulty in achieving high-precision temperature maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

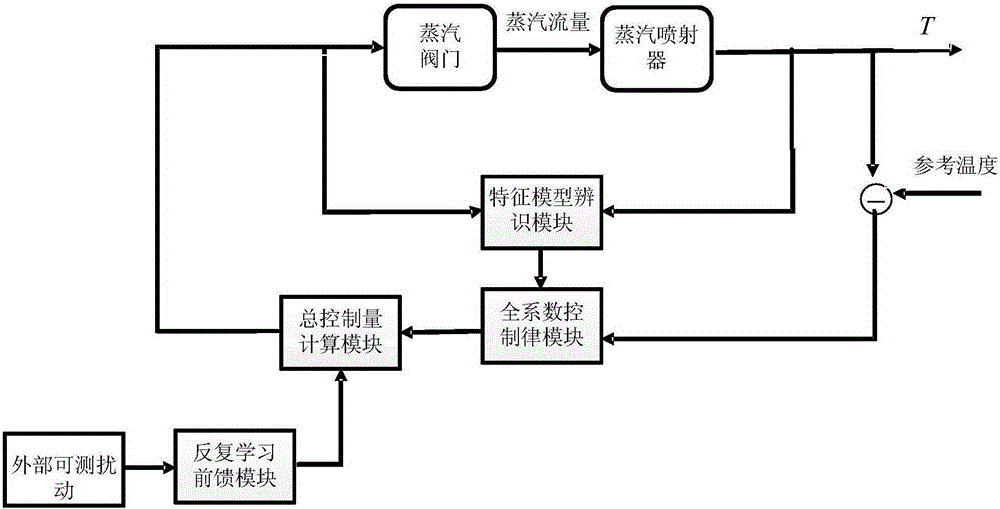

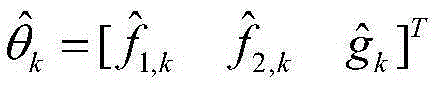

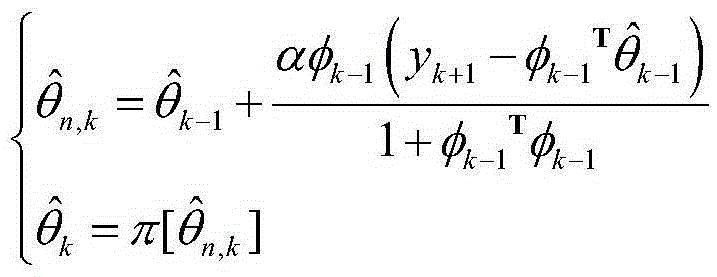

[0022] The present invention proposes a repeated learning self-adaptive controller applied to the automatic control system of continuous sterilization in the production process of biopharmaceuticals. Integrating various information of the continuous elimination process to realize the precise control of the outlet temperature of the steam ejector.

[0023] The present invention not only guarantees the maximum production efficiency (that is, the material flow rate is as large as possible) in the whole continuous elimination process through reasonable planning, but also enables precise control of the outlet temperature of the steam injector. Specifically, the opening of the steam valve is used as the control input, with The outlet temperature of the steam injector is used as the controlled quantity. The whole system adopts the "feedforward + feedback" hybrid control method, and uses the adaptive control method based on the characteristic model to realize the adaptive and robust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com