A net-based printed circuit board

A technology for printed circuit boards and flexible circuit boards, which is applied in the directions of printed circuits, printed circuits, printed circuit components, etc. The effect of fine contact area and enhanced heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

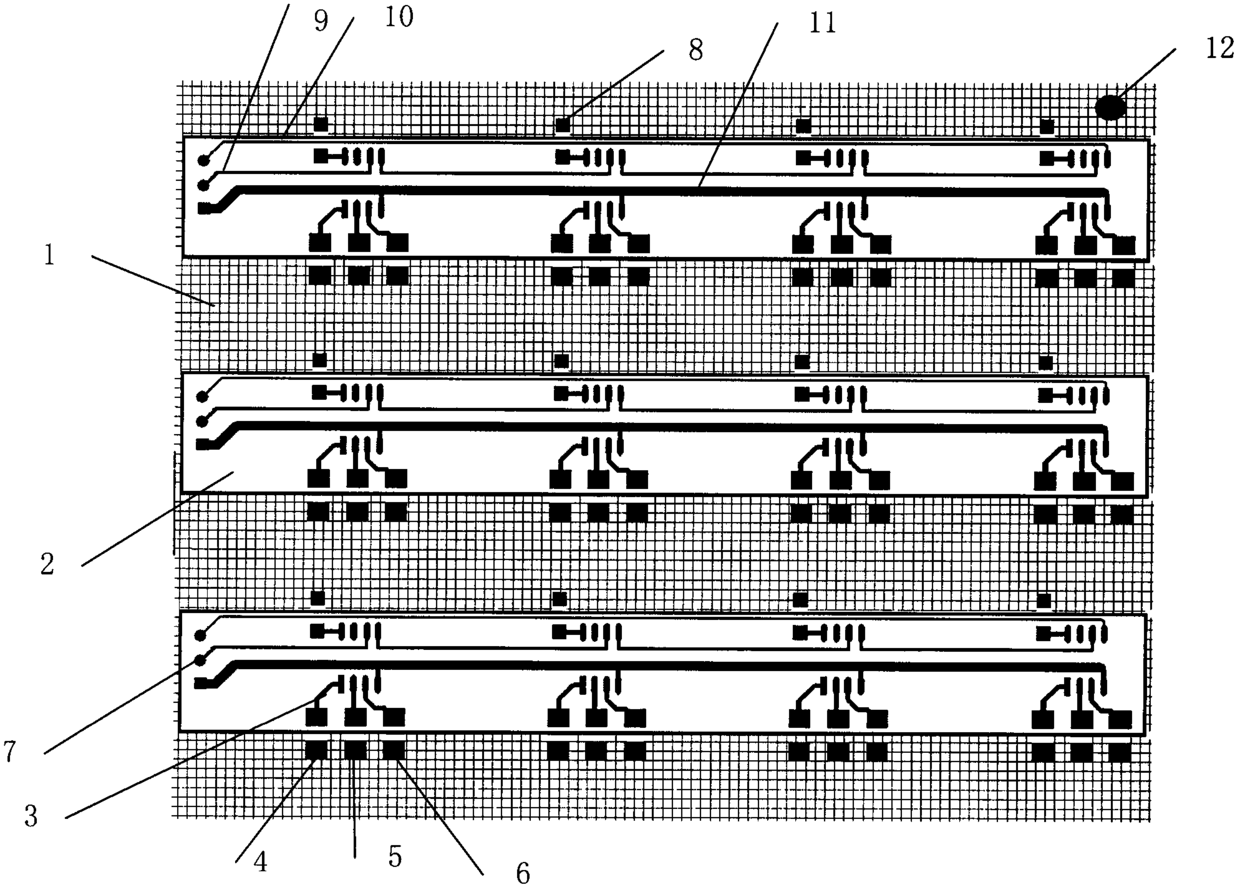

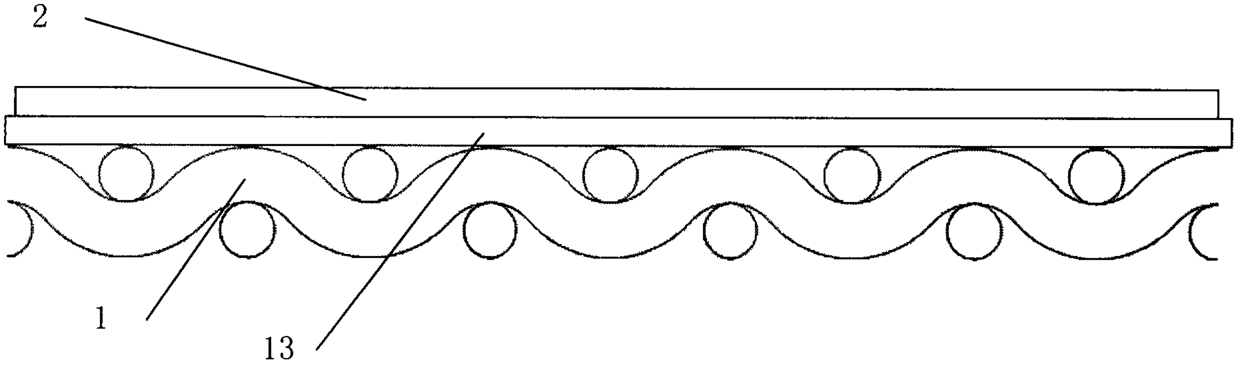

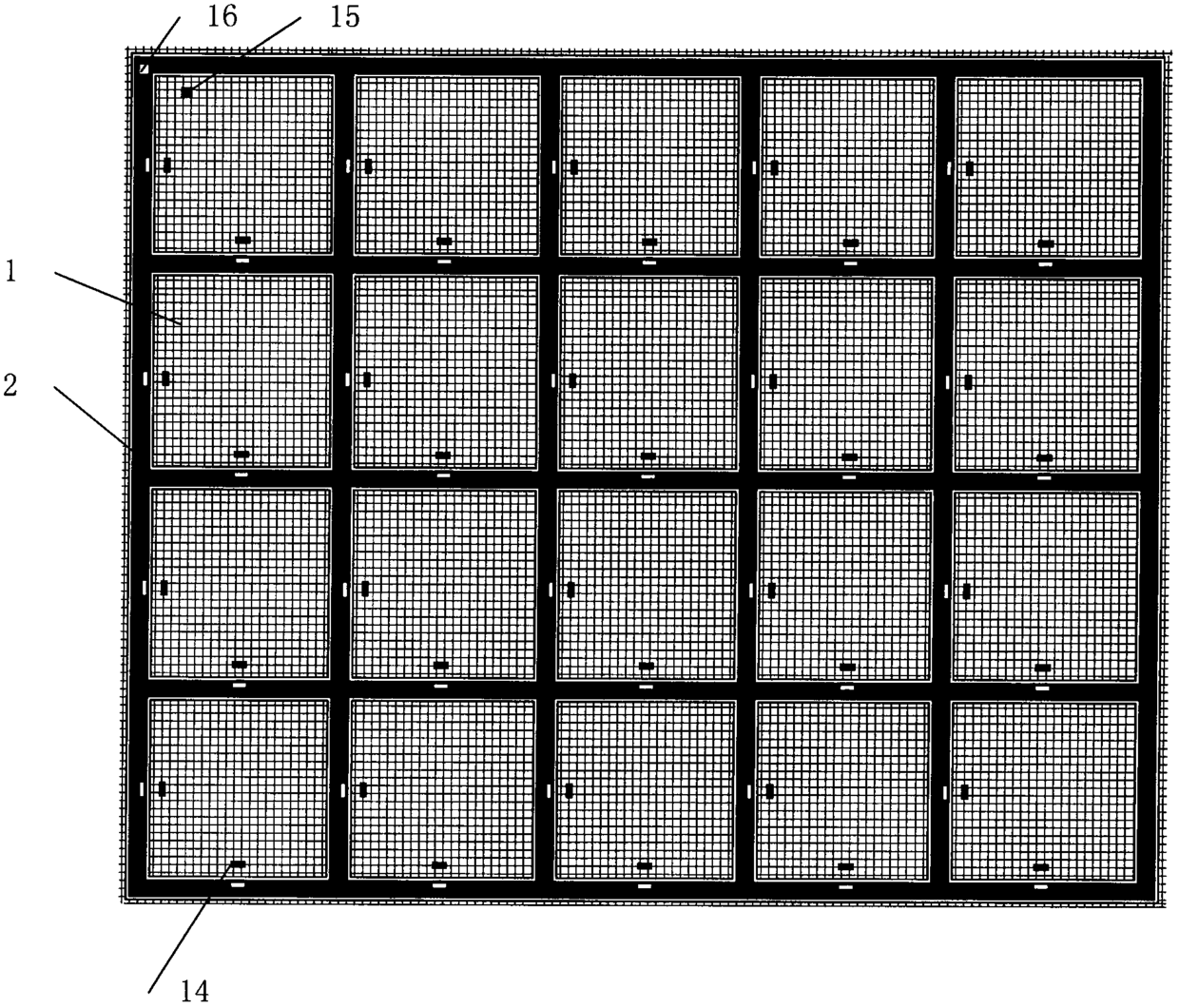

[0024] Such as figure 1 It is a schematic diagram of a top view of a printed circuit board based on a net that is proposed in a preferred embodiment of the present invention. The base net (1) is a 150-mesh copper net (66 microns in wire diameter and 106 microns in aperture), 9 centimeters long, 7 cm wide. There are 3 upper conductive layers (2), which are FR4 thin printed circuit boards with a thickness of 0.2 mm. Three thin printed circuit boards (2) are bonded to the base net (1) at equal intervals with an intermediate adhesive layer (13), and the intermediate adhesive layer (13) adopts a high-temperature-resistant adhesive.

[0025] Apply the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com