Riveting and welding tool for the beam on the inner gantry of forklift trucks

A technology of inner masts and riveting welders, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of low production efficiency, easy deformation of welding, high labor intensity, etc., and achieve high yield, small welding deformation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

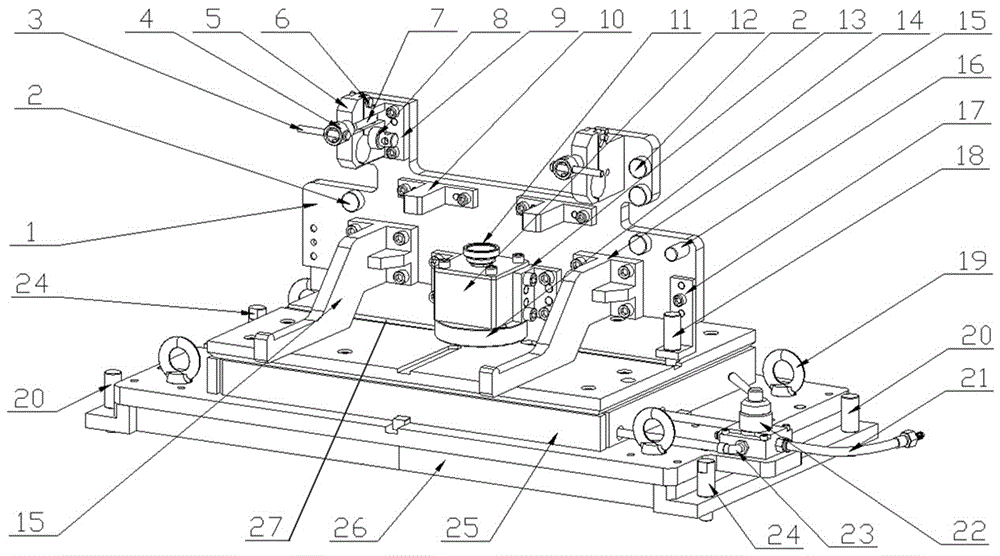

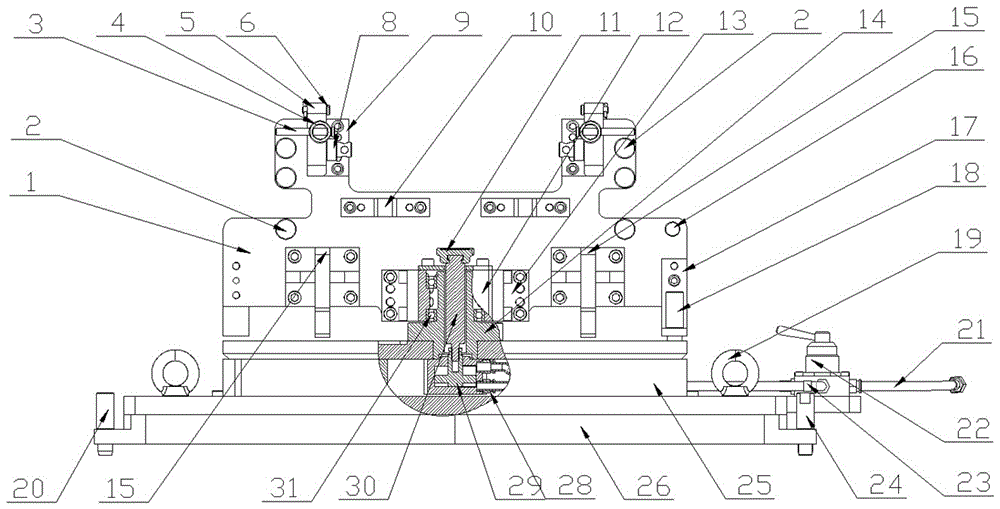

[0039] see figure 1 , used for the riveting and welding tooling of the beam on the inner mast of the forklift, including a base 26, a pneumatic tightening mechanism, and a positioning mechanism; the base 26 is a plate, and the two corners of the base 26 are provided with There is a positioning bolt 20 , locking screw rods 24 are provided at two opposite corners of the base 26 , and lifting rings 19 are provided at four corners of the top plate of the base 26 .

[0040] The top surface of the base 26 is provided with a hollow box-shaped swivel support 25; the middle part of the top plate of the swivel support 25 is provided with a round hole, and the middle part of the top plate of the swivel support 25 is provided with a positioning groove 27 along the length direction. , and a pin hole is provided on the top plate of the swivel support 25 on the front side of one end of the positioning groove 27;

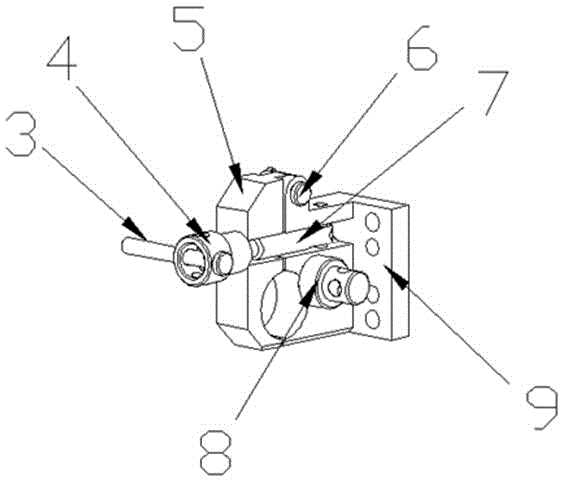

[0041] see Figure 5 , the pneumatic tightening mechanism includes a cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com