Betel nut packing machine

A packaging machine and betel nut technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of slow recovery of investment costs, large floor space, and high input costs, and achieve fast recovery of investment costs, small footprint, and The effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

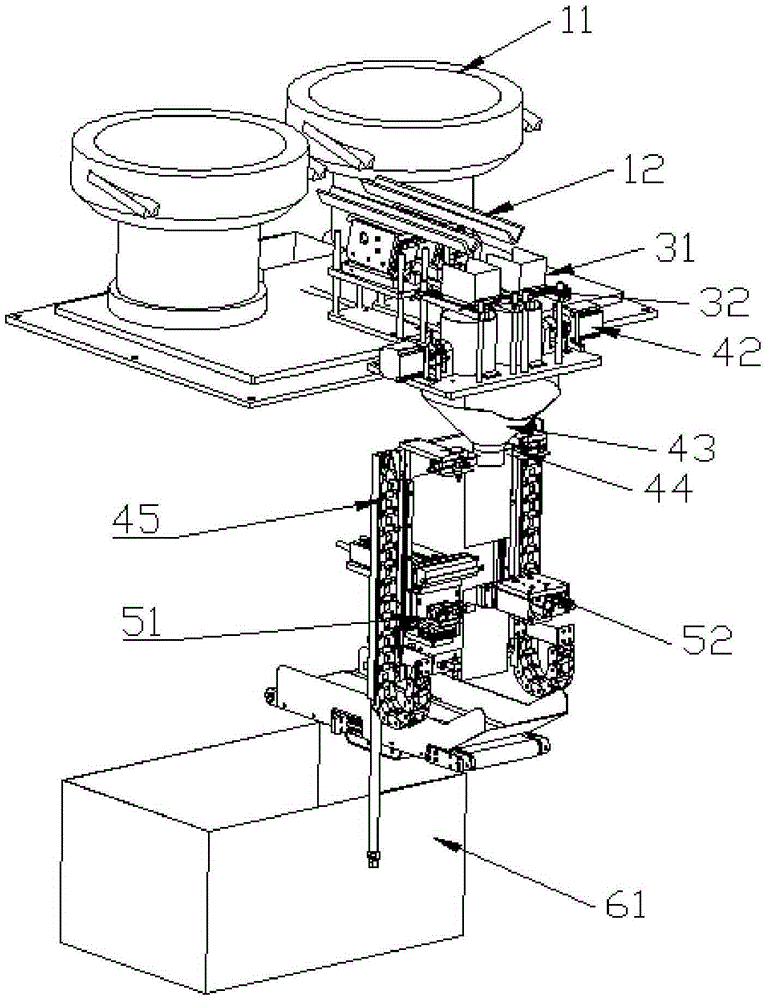

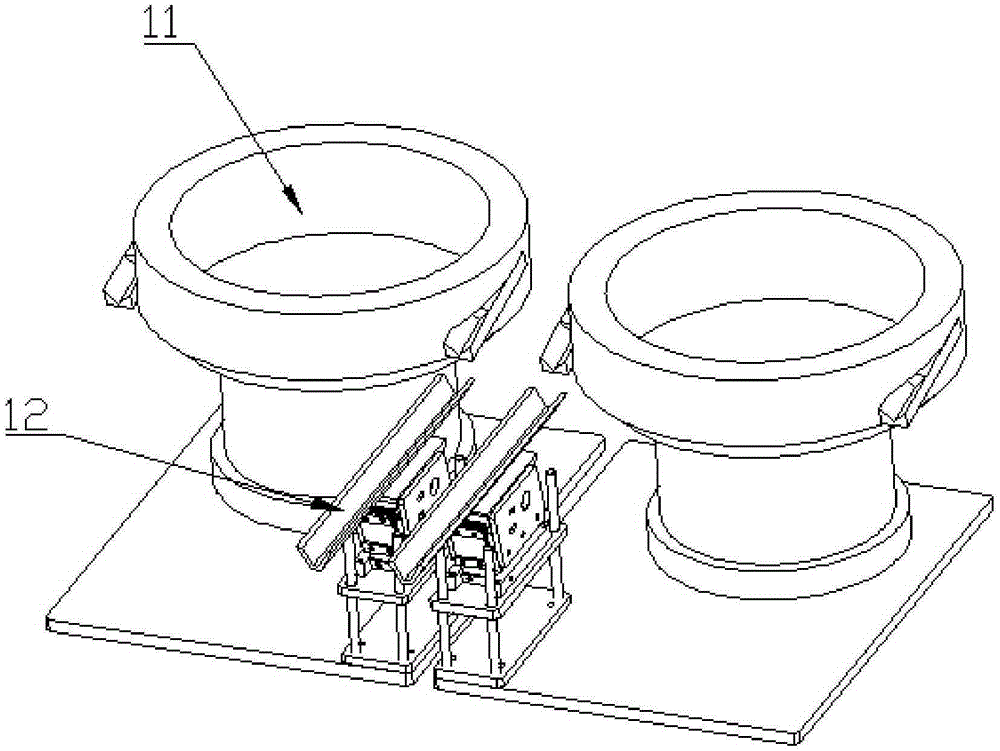

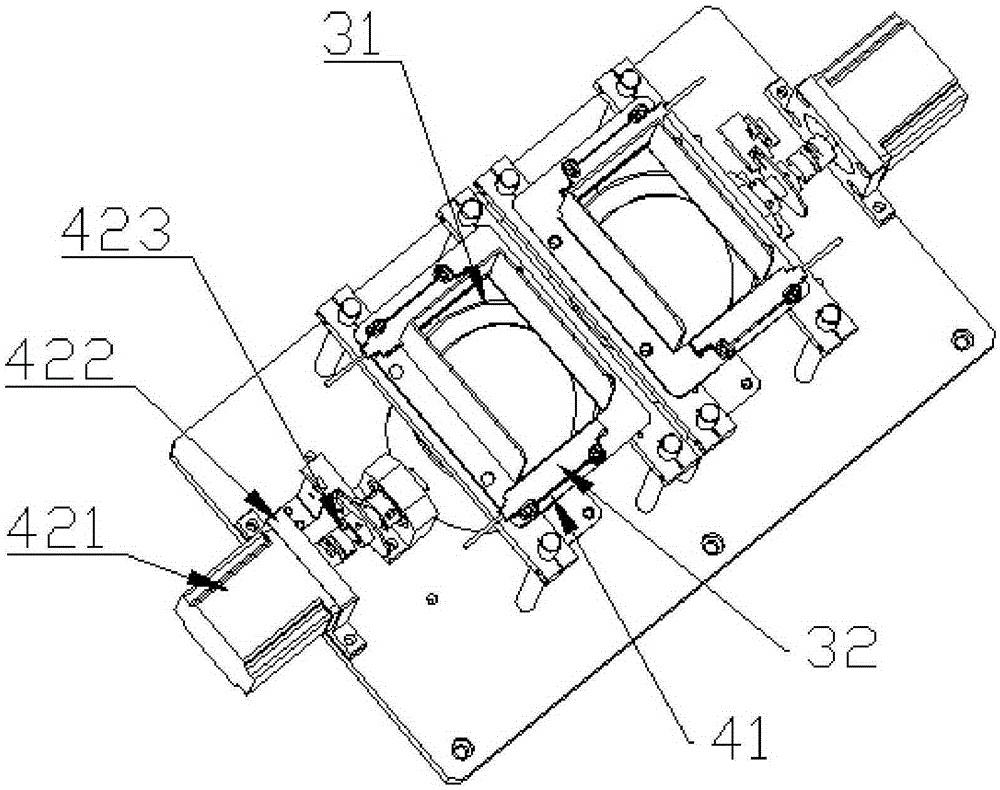

[0030] See attached Figure 1-4 , a kind of betel nut packing machine, comprises frame, and this frame is provided with feeding unit, counting unit, filling unit and sealing unit successively, and described feeding unit includes vibrating plate 11 and smooth flow channel 12, and this vibrating plate A spiral flow channel is provided inside, and a plurality of small holes are arranged on the outermost ring flow channel, and the outlet end of the outermost ring flow channel extends to the outside of the vibrating plate and is dislocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com