Waste-liquid polyphase separation apparatus and waste-liquid separation method

A multi-phase separation and waste liquid technology, which is applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, water/sewage treatment, etc., can solve the problems of accelerated sinking and discharge, so as to avoid dust accumulation and blockage, and facilitate multi-phase Effect of separation and improvement of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

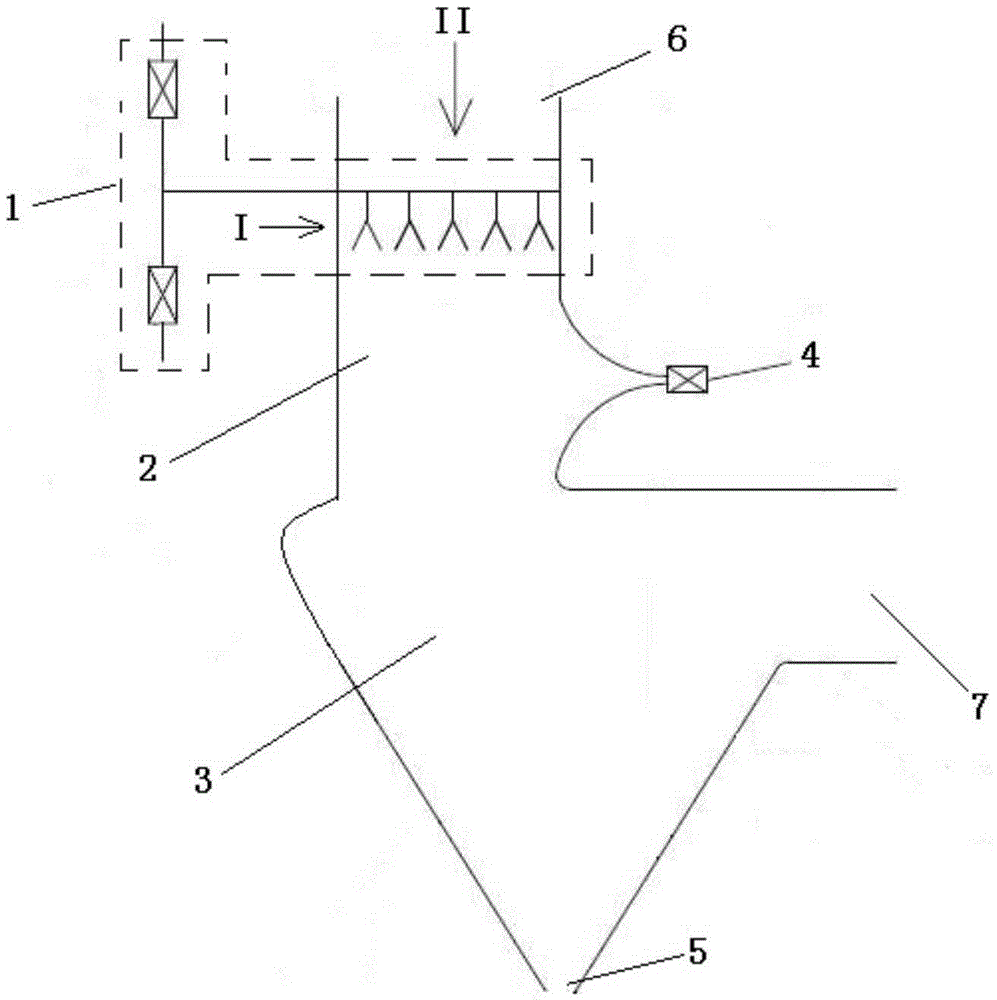

[0039] Such as figure 1 As shown, it is a schematic diagram of the waste liquid multiphase separation device provided in this embodiment, including atomization equipment 1, atomization area 2, static pressure expansion area 3, sounding device 4, ash outlet 5, device inlet 6 and device outlet 7 ; Wherein the atomization device 1 is arranged on the top of the atomization area 2 below the device inlet 6, the static pressure expansion area 3 is arranged under the atomization area 2 and communicates with the atomization area 2, and the flow area of the static pressure expansion area 3 is larger than that of the mist The flow area of the atomization zone 2, the sound generating device 4 is set in the atomization zone 2, the ash outlet 5 is set in the bottom of the static pressure expansion zone 3, and the device outlet 7 is set in the side of the static pressure expansion zone 3.

[0040] The device provided by the invention can well separate the three phases of solid, liquid an...

Embodiment 2

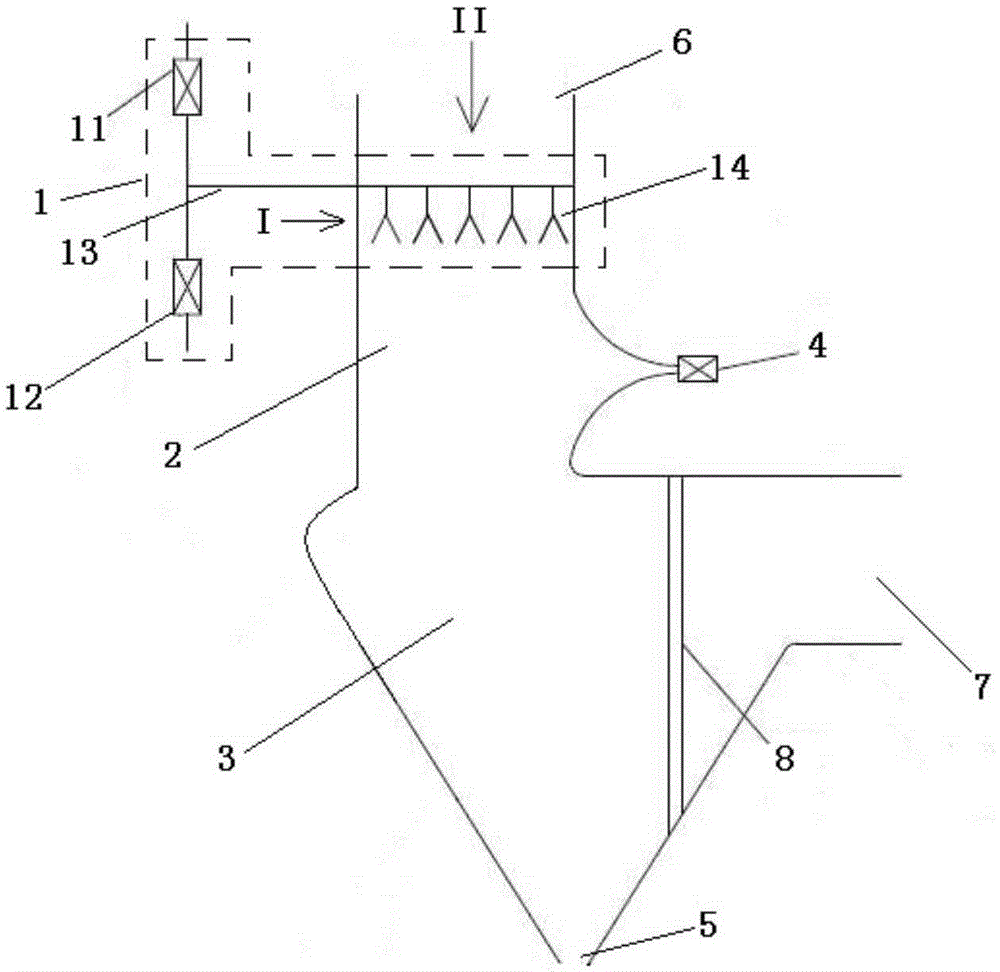

[0042] Such as figure 2 As shown, it is a further improvement on the basis of Embodiment 1, wherein the atomization device 1 includes a high-pressure pump 11, an air compressor 12, an atomization pipeline 13 and an atomization nozzle 14, which can play a good atomization effect and produce sound The device 4 includes a sound generator, a sound conduit and a control system. The control system can control the sound generator to emit sound waves of different frequency bands. The sound waves are sent out through the sound conduit. The sound conduit is arranged on the inner wall of the atomization zone 2, and the exit of the sound conduit faces Inside the atomization zone 2, it is ensured that the sound waves can act on the atomized small droplets to the greatest extent after the sound waves are emitted to produce a cohesive effect. The static pressure expansion area 3 is set so that the upper space is large, and the lower space is gradually reduced, especially it is set as an inv...

Embodiment 3

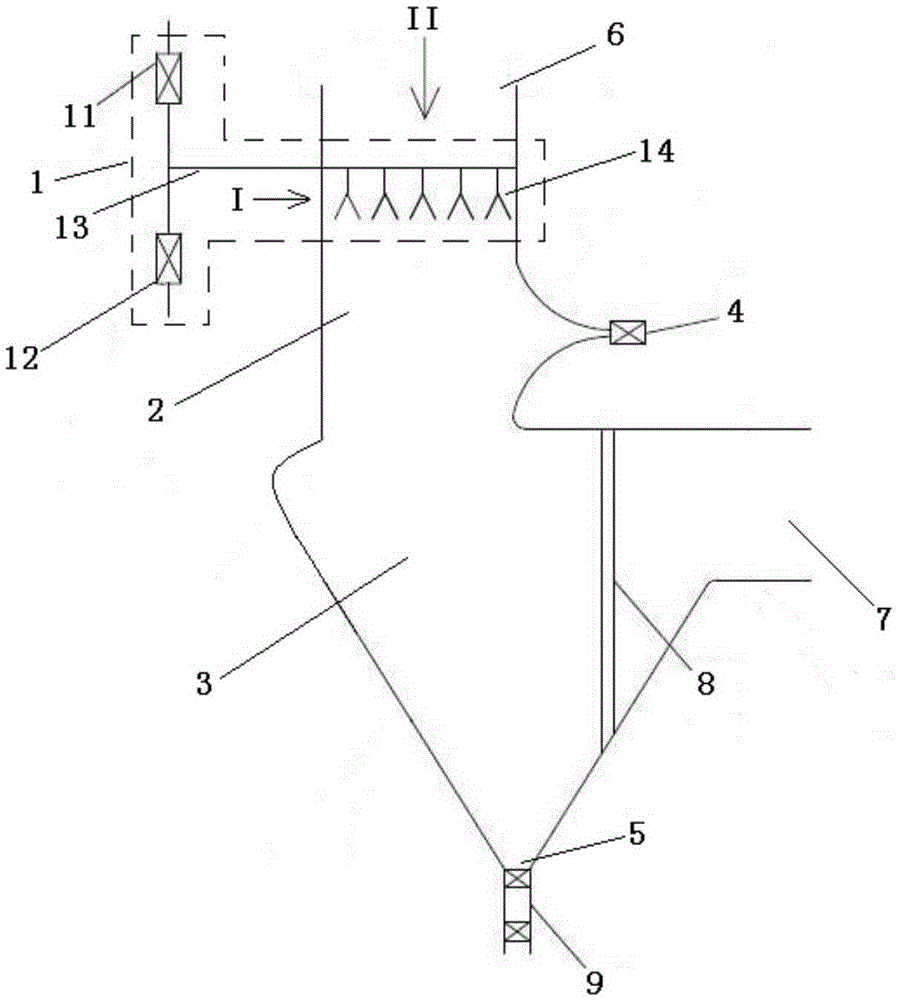

[0044] Such as image 3 As shown, the schematic diagram of the waste liquid multiphase separation device provided in this embodiment is another improvement on the basis of embodiment 2, wherein an ash outlet 9 is connected to the bottom of the ash outlet 5, and the ash outlet 9 It is composed of upper and lower valves and the ash storage tank between them, so that the opening and closing of the ash outlet 5 can be controlled. The upper valve can be opened first, so that the dust enters the ash storage tank. When the ash storage tank is full, Close the upper valve, open the lower valve to release and remove the ash in the ash storage tank, so that the ash storage can continue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com