Discharging device of vertical type solid fuel lime kiln

A solid fuel and unloading device technology, applied in the field of unloading devices, can solve problems such as backward equipment, uneven lime quality, and low product quality, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

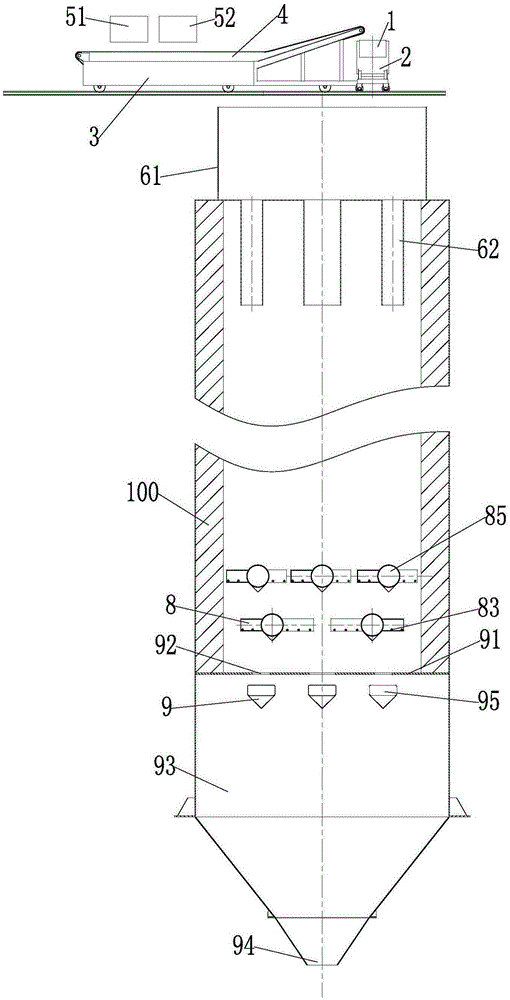

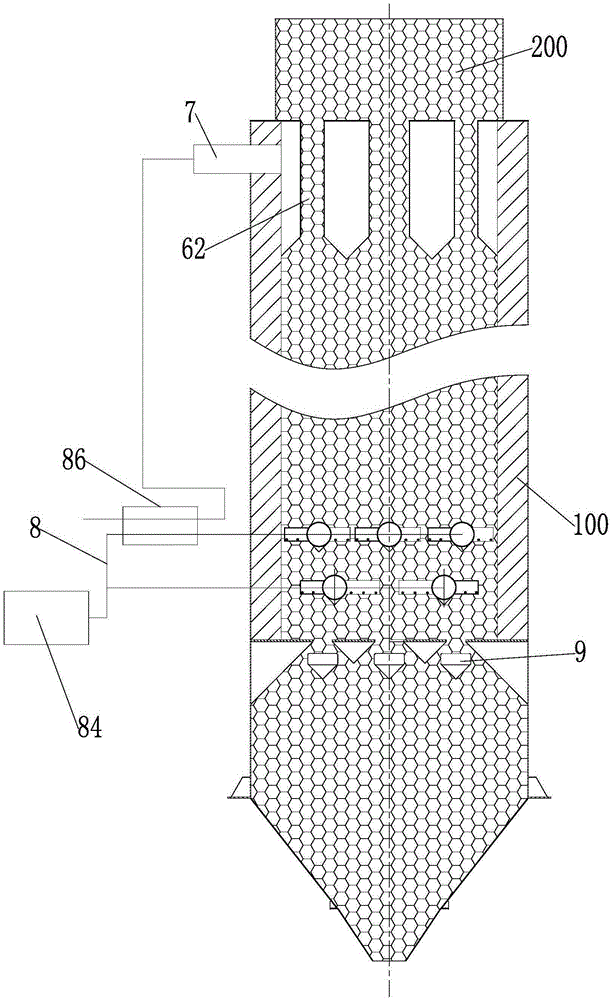

[0067] see figure 1 , 2 The solid fuel vertical lime kiln shown includes a cylinder 100, and a silo 61 with an upper circle and a lower circle is arranged at the upper end of the cylinder; a distributing device is arranged above the silo, and a discharge device 9 is arranged at the lower end of the cylinder. There is an air distribution device 8 above the unloading device.

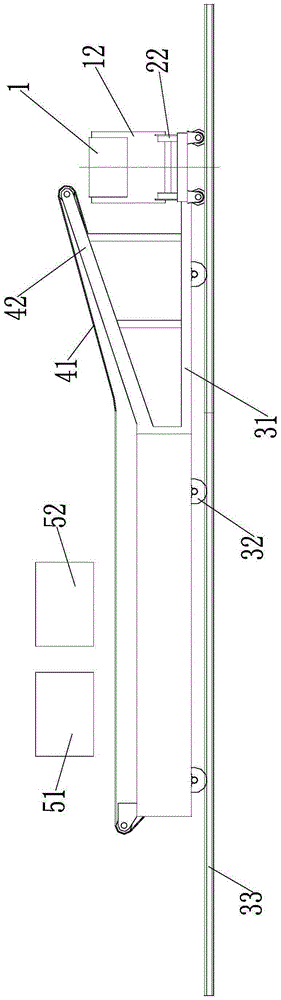

[0068] see image 3 , 4 , the distributing device includes a distributing belt conveyor 1, a longitudinal moving device 2, a lateral moving device 3, and a main belt conveyor 4.

[0069] The cloth belt conveyor 1 includes a conveyor belt 11 for conveying solid fuel and ore raw materials driven by a conveyor belt power device (not shown), a frame 12 for setting the conveyor belt power device, conveyor rollers, etc. The frame 12 is arranged on the longitudinal moving frame 21 (in other words, the frame 12 and the longitudinal moving frame 21 are integrated).

[0070] The longitudinal moving device 2 inc...

Embodiment 2

[0085] see Figure 12 The solid fuel vertical lime kiln shown includes a cylinder body 2100, and a plurality of conical buckets 297 with upper and lower dimensions are arranged at the bottom of the cylinder, and a discharge port (discharging channel) 2971 is provided under each conical bucket; There is a conventional manual, electric, pneumatic, hydraulic and other unloading machines 29 below the first feeding port. Below each unloader 29 is provided with a finished product conveying device 298 connected to the outlet of the unloader.

[0086] The air distribution device 28 includes a fan, and a two-layer air duct 285 communicated with the fan that extends into the cylinder and is staggered up and down. The air outlet of the blower communicates with the upper air duct through the heat exchanger 286 . The flue gas discharged from the flue gas discharge pipe enters the heat exchanger through the flue gas inlet 2861 and then is emptied through the flue gas outlet 2862 or underg...

Embodiment 3

[0090] see Figure 13 The solid fuel vertical lime kiln shown includes a cylinder body 3100, and a plurality of unloading channels 3971 are arranged at the bottom of the cylinder body; an upper unloading machine 391 and a lower unloading machine 392 are arranged in each unloading channel. The upper unloader 391 and the lower unloader 392 are conventional manual, electric, pneumatic, hydraulic and other unloaders. Below the lower unloader 392, a finished product conveying device 398 connected to the outlet of the lower unloader is provided. When the upper unloader operates, the material enters the channel between the cylinder and the lower unloader; when the lower unloader operates, the material between the upper unloader and the lower unloader falls onto the finished product conveying equipment. The upper unloading machine and the lower unloading machine operate in sequence, and also play the role of unloading and locking air.

[0091] Other components of the solid fuel vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com