A ceramic tile adhesive with the function of waterproofing tiles

A tile adhesive and functional technology, applied in the field of tile adhesives, can solve the problems of waterproof layer only focusing on waterproof effect, ignoring whether the tiles are firm, increasing construction costs, etc., achieving the effect of solving the problem of brick falling, excellent ductility, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

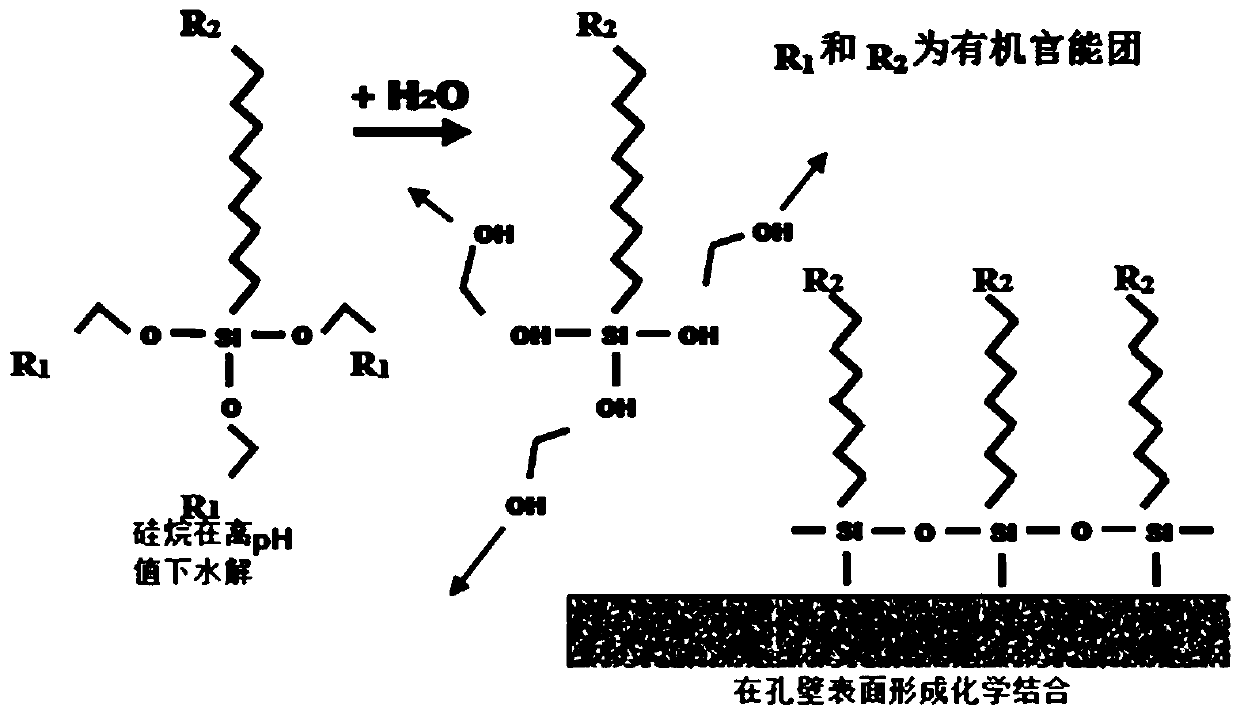

Method used

Image

Examples

Embodiment 1

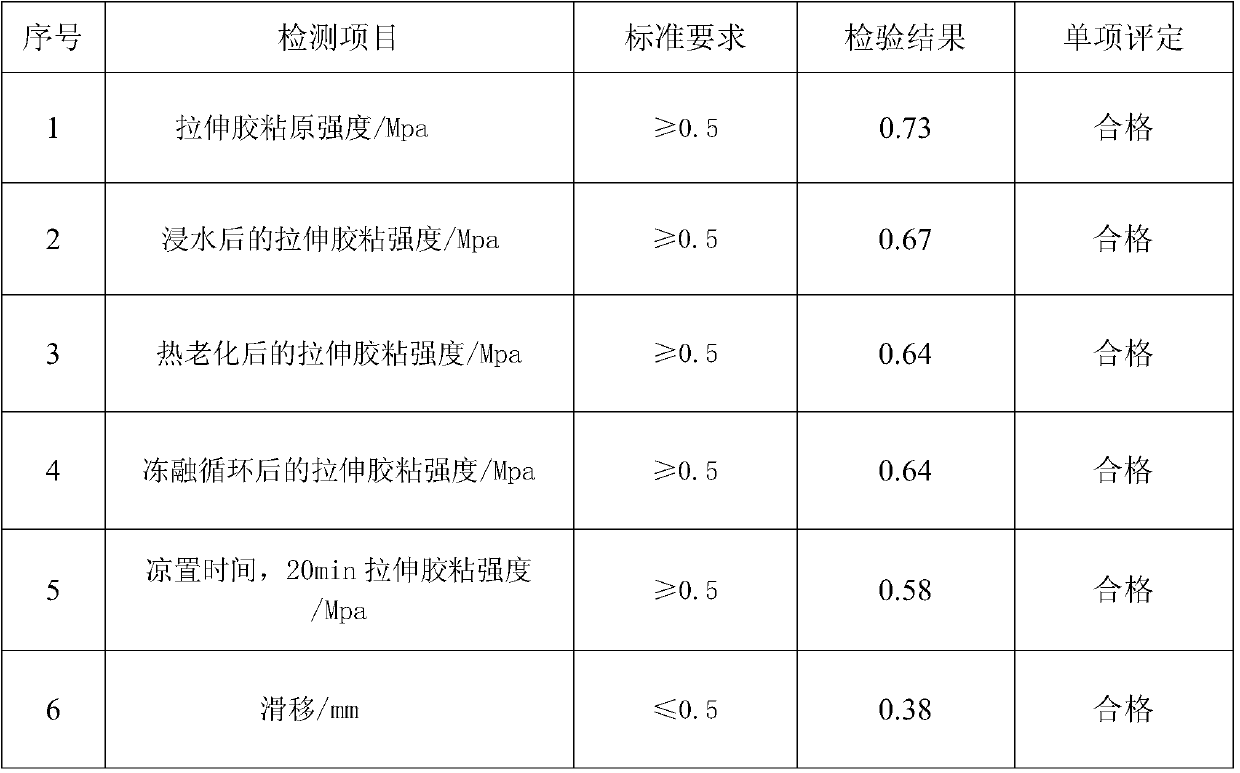

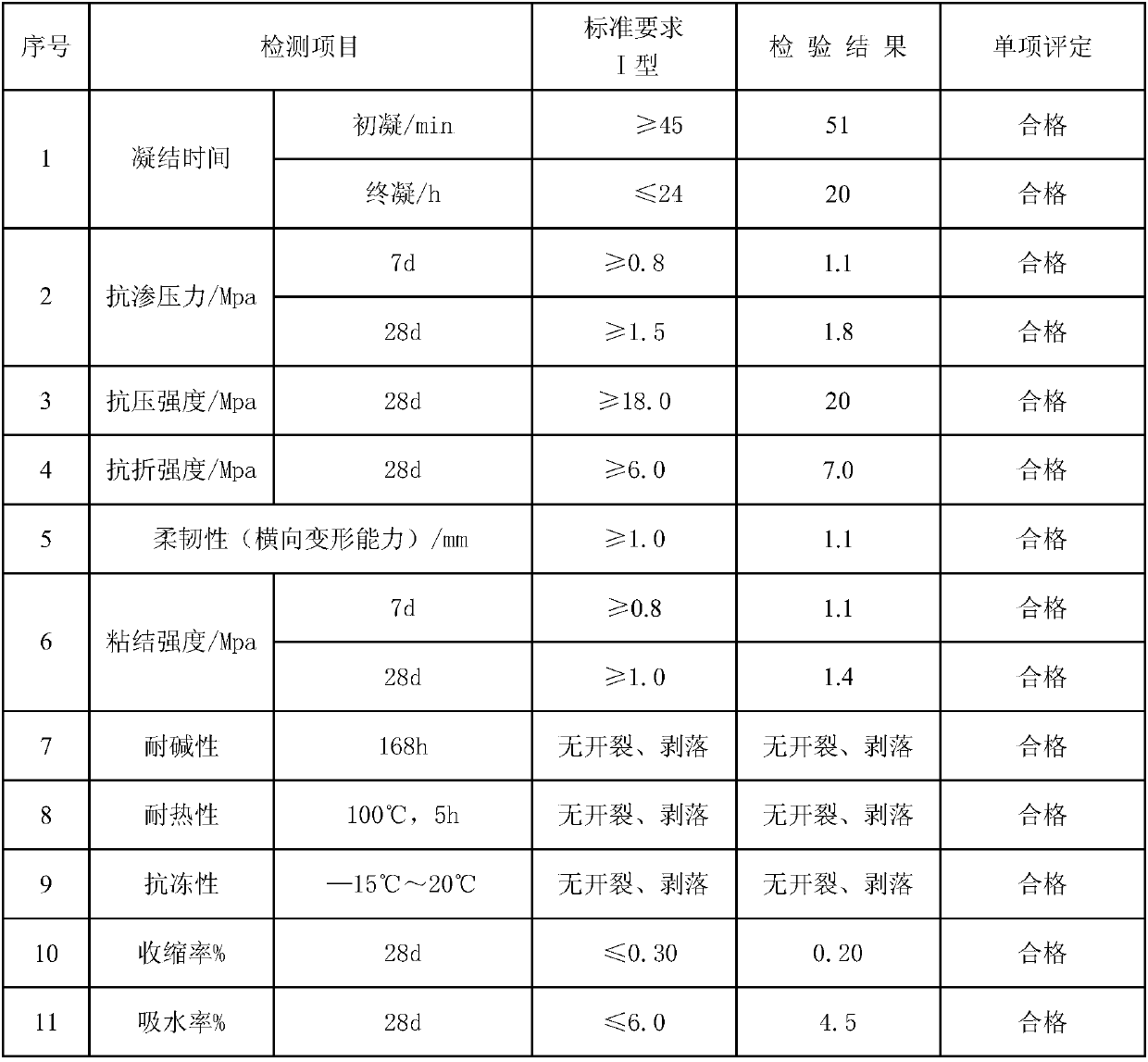

[0028] A tile adhesive, the proportion is: 15 parts of Wacker 316 rubber powder, 15 parts of Wacker 8031H rubber powder, 4 parts of 33SK cellulose ether, 2 parts of CF-1 polypropylene fiber, 6 parts of SEAL80 Water agent, 3 parts of AGITAN P803 defoamer, 3 parts of BASF F10 water reducer, 2 parts of ZZC 540 wood fiber, 450 parts of cement, 300 parts of 100-mesh high-quality quartz sand, 150 parts of 150-mesh high-quality quartz Sand, 60 parts of 200 mesh high-quality quartz sand and 800 parts of water. The ceramic tile adhesive that will obtain is tested the performance of ceramic tile adhesive according to the regulation of national building materials industry standard JC / T 547-2005 " ceramic wall and floor tile adhesive " and JC / T 984-2011 " polymer cement waterproof mortar ", the result sees table 1 and table 2.

Embodiment 2

[0030] A tile adhesive, the proportion is: 18 parts of Wacker 316 rubber powder, 20 parts of Wacker 8031H rubber powder, 5 parts of 33SK cellulose ether, 3 parts of CF-1 polypropylene fiber, 7 parts of SEAL80 Water agent, 4 parts of AGITAN P803 defoamer, 4 parts of BASF F10 water reducer, 3 parts of ZZC 540 wood fiber, 480 parts of cement, 330 parts of 100-mesh high-quality quartz sand, 180 parts of 150-mesh high-quality quartz Sand, 70 parts of 200 mesh high-quality quartz sand and 1200 parts of water. The ceramic tile adhesive that will obtain is tested the performance of ceramic tile adhesive according to the regulation of national building materials industry standard JC / T 547-2005 " ceramic wall and floor tile adhesive " and JC / T 984-2011 " polymer cement waterproof mortar ", the result sees table 1 and table 2.

[0031] Table 1: Test results of JC / T 547-2005 "Ceramic tile adhesive"

[0032]

[0033] Table 2: Inspection results of JC / T 984-2011 "Polymer Cement Waterpr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com