Concrete Surface Coloring Composition

A concrete surface and coloring composition technology, which is applied in the field of concrete surface coloring compositions, can solve the problems of undisclosed components and contents, separate and cumbersome coloring process, etc., and achieve the effect of stabilizing color performance and preventing spots or color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Methyl methacrylate is used as the methacrylate, and greenb green dye formed from 0.01-1.0nm powder is used as the coloring agent, but not limited thereto, and inorganic or organic pigments formed from 100nm-1μm powder can be used. The diluent is mixed with ion-exchanged water and ethylene glycol in a weight ratio of 7:3, and their weight ratio can be added or subtracted according to specific conditions, or just water or glycol.

[0038]Mix green b green pigment, thinner (water + ethylene glycol), methyl methacrylate, polydimethylsiloxane, fluoropolymer, colloidal silica, and modified silicate in a ratio of 8:45 The weight ratio of :7:0.06:0.5:6:25 was mixed using an automatic mixer at room temperature, and the total amount of the composition at this time was 1L.

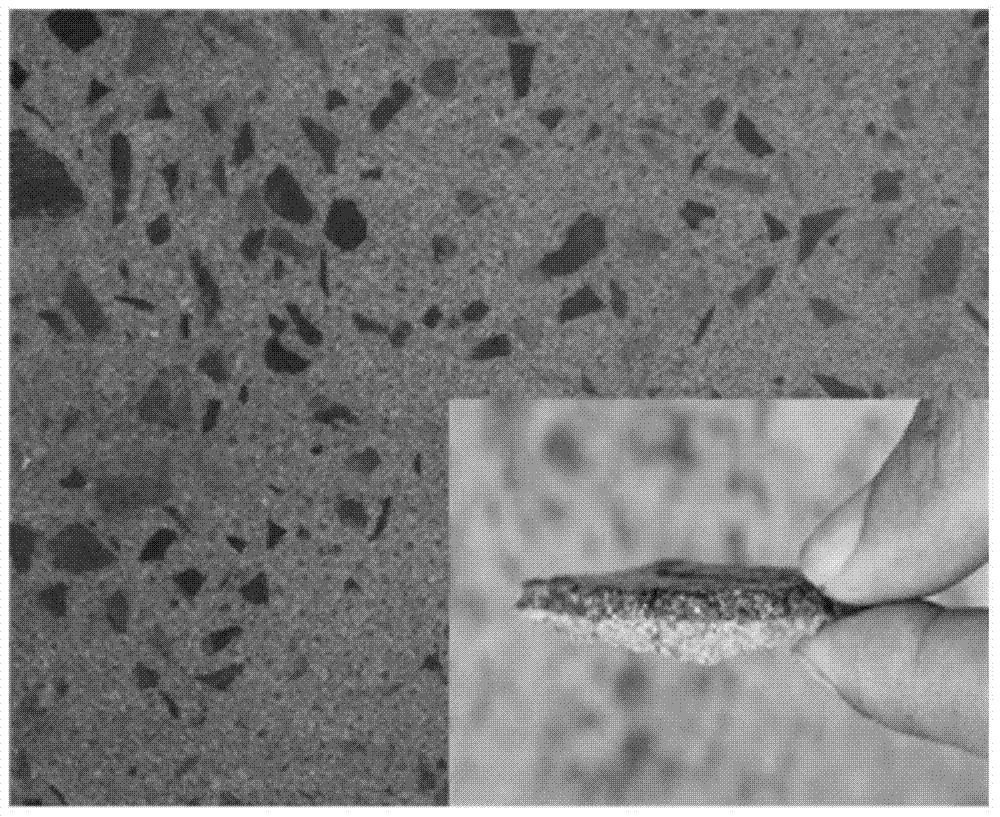

[0039] Concrete drilling test pieces were prepared on the basis of 15 days of curing at room temperature under the condition of 15Mpa. After surface grinding and polishing, the coloring composition of Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com