Two-component self-luminous modified marking latex and application method thereof

A self-illuminating, two-component technology, applied in luminescent paint, latex paint, road signs, etc., can solve the problems of easy traffic accidents, inaccurate line shape judgment, narrow driver's vision, etc., to achieve easy promotion and low production cost The effect of low cost and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

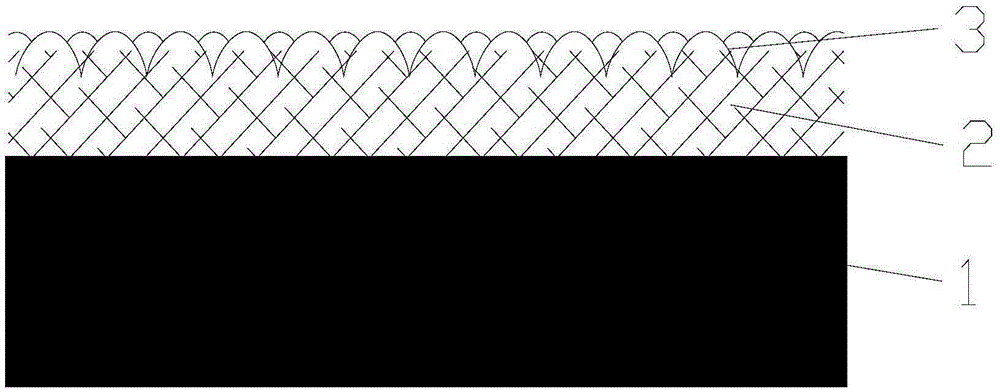

Method used

Image

Examples

Embodiment 1

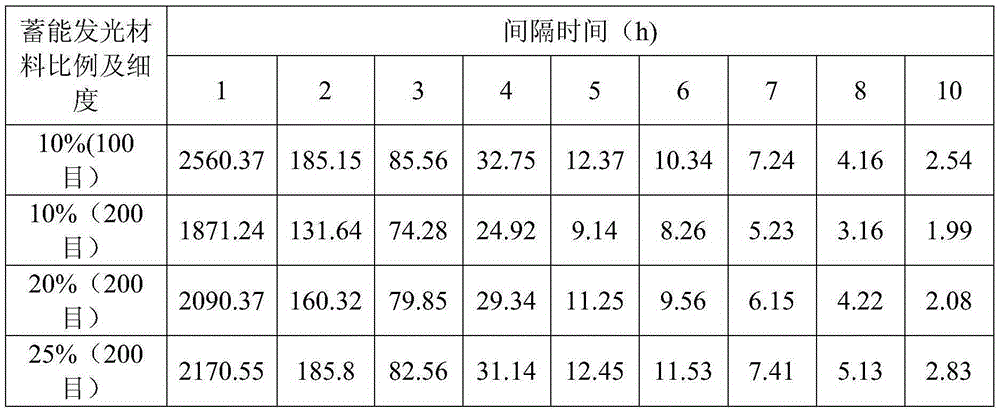

[0019] This embodiment discloses a two-component luminescent marking paint, including the following components in parts by weight: 150 parts of E51 epoxy resin and polyamide 650 curing agent (A:B=3:1), 5 parts of glass fiber powder , 15 parts of high-purity quartz sand, 15 parts of titanium dioxide, 18 parts of glass beads, 1.0 parts of dispersant, 1.0 parts of diisooctyl phthalate, 2 parts of toluene, energy storage luminescent material SrAl 2 o 4 :Eu 2+ , Dy 3+ 15 servings.

[0020] Put the above-mentioned raw materials into the mixer and stir at room temperature to obtain a uniformly mixed self-illuminating marking paint. When it reaches a consistency that can be used for construction, it is evenly coated on ordinary hot-melt road markings with a thickness of 1 mm. The marking film is milky white, with a smooth appearance, indicating that the suspension rate of glass beads is not less than 75%, and has good reflective and luminous performance. The energy storage luminesc...

Embodiment 2

[0022] This embodiment discloses a two-component luminous marking paint, including the following components in parts by weight: 150 parts of E51 epoxy resin and polyamide 650 curing agent (A:B=3:1), 200 mesh glass fiber powder 5 parts, 15 parts of 20-40 mesh high-purity quartz sand, 3 parts of fluorescent pigment, 0.05 part of ultraviolet absorber, 18 parts of 20-40 mesh glass beads, 1.0 part of dispersant, 1.0 part of diisooctyl phthalate, 2 parts of toluene, energy storage luminescent material SrAl 2 o 4 :Eu 2+ , Dy 3+ 15 servings.

[0023] Put the above-mentioned raw materials into a mixer and stir at room temperature to obtain a light yellow self-luminous marking paint that is evenly mixed. When it reaches a consistency that can be used for construction, it is evenly coated on ordinary hot-melt road markings with a thickness of 1 mm. The marking film is light yellow, smooth in appearance, the suspension rate of glass beads on the surface is not less than 75%, good refl...

Embodiment 3

[0025] This embodiment discloses a two-component luminous marking paint, including the following components in parts by weight: 150 parts of E51 epoxy resin and polyamide 650 curing agent (A:B=3:1), 200 mesh glass fiber powder 10 parts, 5 parts of 20-40 mesh high-purity quartz sand, 15 parts of titanium dioxide, 25 parts of 20-40 mesh glass beads, 2.0 parts of dispersant, 1.0 parts of diisooctyl phthalate, 2 parts of toluene, energy storage Luminescent material SrAl 2 o 4 :Eu 2+ , Dy 3+ 15 servings.

[0026] Put the above-mentioned raw materials into a stirrer, and stir at room temperature to obtain a uniformly mixed white self-luminous marking paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com