Energy-storing self-luminescent road marking coating

A road marking and self-luminous material technology, applied in the field of road marking paint, road marking and safety signs, can solve the problem that pedestrians cannot see the marking, reduce the recognizability of marking, and can identify the marking. Poor performance and other problems, to achieve the effect of good energy storage, self-luminous and reflective functions, good luminous recognition, and long luminous time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

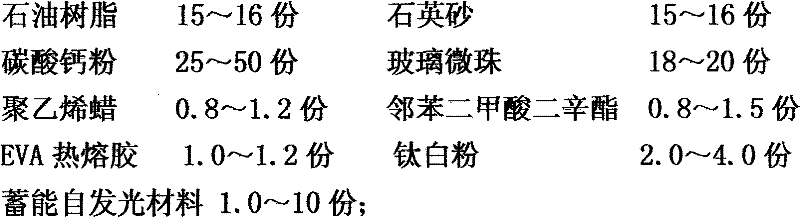

[0027] Example 1 The raw materials were taken according to the following parts by weight, wherein the energy storage luminescent material is a rare earth type self-luminous material, and the petroleum resin is a commercially available C5 special resin for road marking paint:

[0028] 16 parts of petroleum resin 16 parts of 40-80 mesh quartz sand

[0029] 40-200 mesh calcium carbonate powder 15 parts 325 mesh calcium carbonate powder 25 parts

[0030] 20 parts of glass microspheres 0.8 parts of polyethylene wax

[0031] Dioctyl phthalate 1.2 parts EVA hot melt adhesive 1.2 parts

[0032] Titanium dioxide 3.0 parts Energy storage luminescent material 1.0 parts

[0033] The above-mentioned raw materials are put into a mixer and stirred at normal temperature to obtain a uniformly mixed white energy-storage self-luminous road marking paint. After heating and melting, the road construction is carried out. The marking film is milky white, the appearance is smooth and smooth, the s...

Embodiment 2

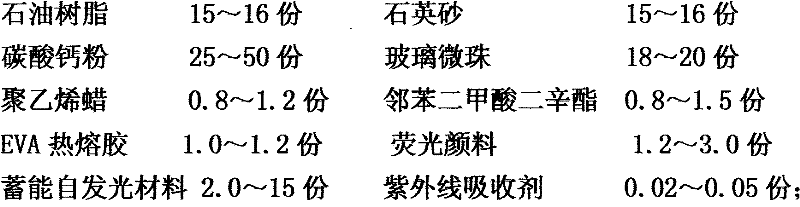

[0034] Example 2 The raw materials were taken according to the following parts by weight, wherein the energy storage luminescent material is a rare earth self-luminous material, and the petroleum resin is a commercially available C5 special resin for road marking paint:

[0035] 15 parts of petroleum resin 15 parts of 40-80 mesh quartz sand

[0036] 20 parts of 40-200 mesh calcium carbonate powder 20 parts of 300 mesh calcium carbonate powder

[0037] 18 parts of glass microspheres 1.2 parts of polyethylene wax

[0038] Dioctyl phthalate 1.5 parts EVA hot melt adhesive 1.0 parts

[0039] Fluorescent pigment 1.3 parts Energy storage self-luminous material 2.0 parts

[0040] Ultraviolet absorber UV531 0.03 parts

[0041] Put the above-mentioned raw materials into a mixer and stir at room temperature to obtain a uniformly mixed yellow energy-storage self-luminous road marking paint. After heating and melting for road construction, the appearance of the marking coating film is...

Embodiment 3

[0042] Example 3 The raw materials were taken according to the following parts by weight, wherein the energy storage luminescent material is a rare earth type self-luminous material, and the petroleum resin is an aromatic hydrocarbon petroleum resin for commercially available C9 road marking paint:

[0043] 15 parts of petroleum resin 15 parts of 40 mesh quartz sand

[0044]20 parts of 40-200 mesh calcium carbonate powder 21 parts of 350 mesh calcium carbonate powder

[0045] 20 parts of glass microspheres 1.2 parts of polyethylene wax

[0046] Dioctyl phthalate 0.8 parts EVA hot melt adhesive 1.0 parts

[0047] Titanium dioxide 3.0 parts Energy storage luminescent material 10.0 parts

[0048] The above-mentioned raw materials are put into a mixer and stirred at normal temperature to obtain a uniformly mixed white energy-storage self-luminous road marking paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com