Composite additive applied in fuel gas gasoline engine lubricating oil

A gasoline engine and compound additive technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of unsatisfactory use effect, high price, single efficacy, etc., achieve scientific and reasonable solutions, improve environmental protection requirements, and strong repair functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

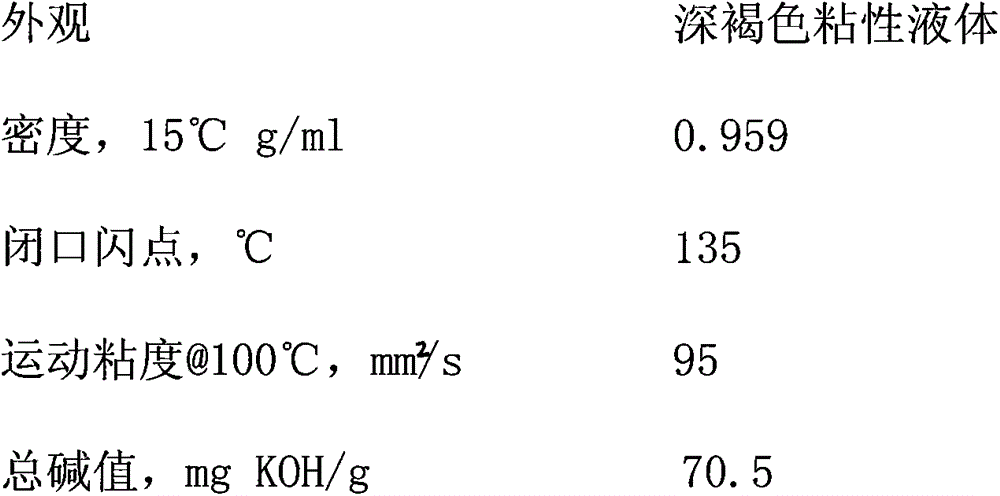

Image

Examples

Embodiment 1

[0019] A compound additive used in gas gasoline engine lubricating oil, consisting of base oil; alkyl diphenylamine; calcium hydroxide; polyisobutylene; polyoxyl polyol; polyacrylate; ethoxylated phenols; dithio Phosphate ester; boride-based cermet; copper oxide; zinc oxide composition, the base oil is a mixture of three components of polyalpha olefin, polyether and polyol grease, and the weight share ratio of the three components is 1 :1:1. The weight percent of each component is: base oil 55%; alkyl diphenylamine 5%; calcium hydroxide 3%; polyisobutylene 2%; polyalkoxy polyol 6%; polyacrylate 6%; Phenols 8%; Dithiophosphate 7%; Boride-based cermets 3%; Copper oxide 3%; Zinc oxide 2%, base oil; Alkyl diphenylamine; Calcium hydroxide; Polyisobutylene; polyacrylic acid esters; ethoxylated phenols; dithiophosphates; boride-based cermets; copper oxide; Between 60-70°C, stir for 180 minutes, and filter to obtain the product of the present invention.

[0020] Comparing this prod...

Embodiment 2

[0029] A composite additive used in gas gasoline engine lubricating oil, consisting of base oil; alkyl diphenylamine; calcium hydroxide; polyisobutylene; polyalkoxy polyol; polyacrylate; ethoxylated phenols; dithio Phosphate ester; boride-based cermet; copper oxide; zinc oxide, the base oil polyalpha olefin and polyol grease are mixed, and the weight ratio of the two components is 3:1. The weight percentage of each component is: base oil 30%; alkyl diphenylamine 9%; calcium hydroxide 5%; polyisobutylene 3%; polyalkoxy polyol 8%; polyacrylate 10%; 12% phenols; 9% phosphorodithioate; 5% boride-based cermet; 6% copper oxide; 3% zinc oxide, base oil; alkyl diphenylamine; calcium hydroxide; polyisobutylene; polyoxygen polyacrylic acid esters; ethoxylated phenols; dithiophosphates; boride-based cermets; copper oxide; Between 60-70°C, stir for 240 minutes, and the product of the present invention is obtained after filtration.

[0030] Comparing this product with other similar produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com