Method for rapidly and ecologically treating coastal beach sludge

An ecological and silt technology, applied in soil protection, sheet pile walls, water filling and land construction, etc., can solve problems such as complex processing and long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

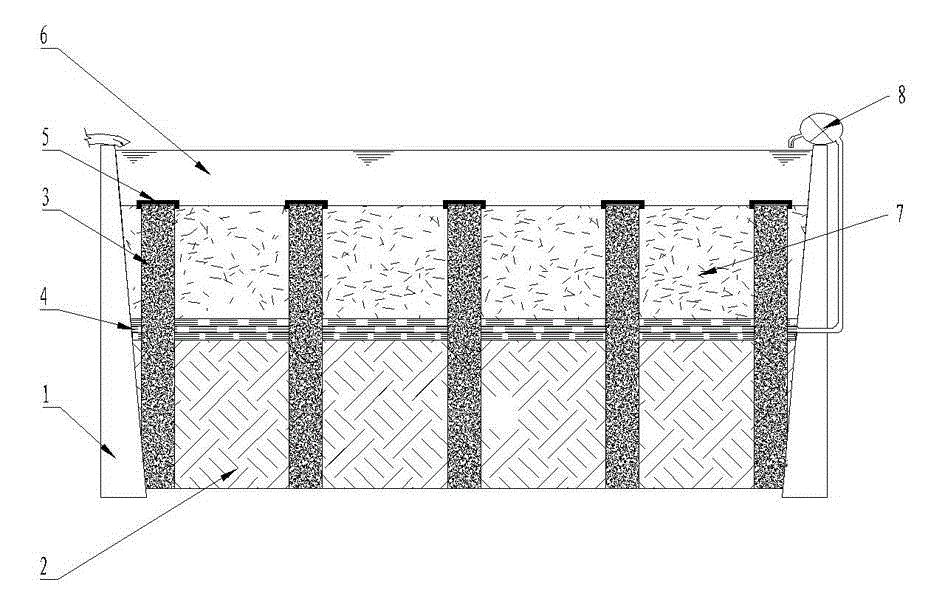

[0027] A method for rapid ecological treatment of beach mud in this embodiment, the following steps are performed in sequence:

[0028] 1) Build a cofferdam 1 on the coastal tidal flats and blow fill the silt into the cofferdam 1. When the elevation of the silt in the cofferdam 1 reaches the first preset elevation (here the elevation can be adjusted according to the actual situation, mainly according to engineering volume selection), stop blowing and filling the silt into the cofferdam 1, and lay several layers of straw blankets 4 on the silt in the cofferdam 1, the straw blankets 4 are formed by weaving, and the thickness of each layer of straw blankets 4 is 5-10cm. 8cm is better, the density is 100~200kg / m 3 Between, at 150kg / m 3 It is better to lay 4-6 layers in total, preferably 5 layers, and the total thickness is between 20-50cm, preferably 40cm;

[0029] 2) Continue blowing and filling the sludge on the upper layer of the straw blanket 4, and stop blowing and filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com