Prefabricated out-hung wall panel construction method

An external wall panel, prefabricated assembly technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of small volume and falling blocks, achieve simple construction method, reduce the amount of cast-in-place, and eliminate the safety factor. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

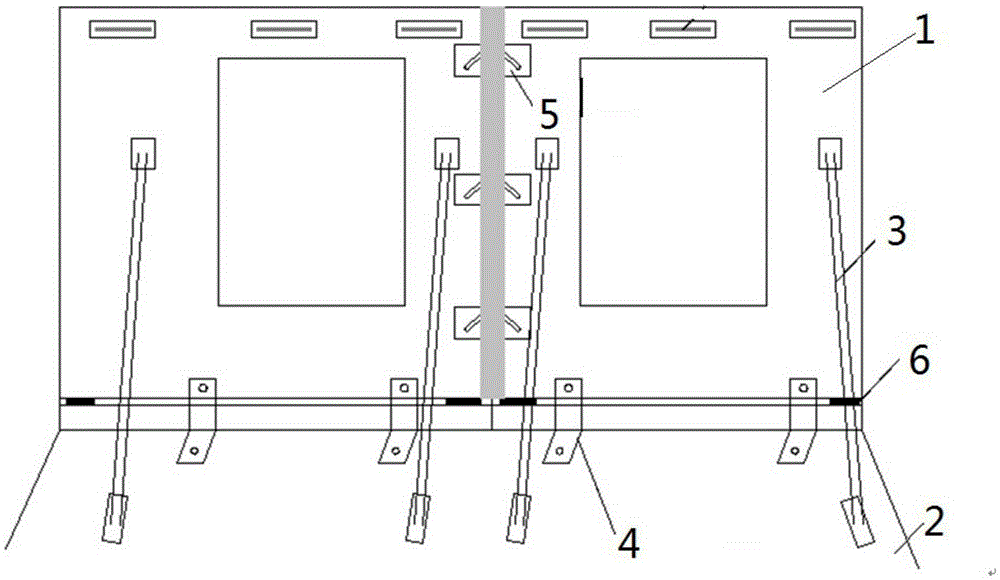

[0044] see figure 1 , the construction method of the prefabricated external wallboard comprises the following steps:

[0045] (1) After checking the elevation of the axis, compare the elevation deviation measured by the level with the height of the block to determine the level of the prefabricated external hanging wall panel 1's location reference plane;

[0046] (2) Hoist several prefabricated and assembled external wall panels 1 to the top of the floor 2 with a tower crane, and then drop the prefabricated and assembled external wall panels 1 to the floor 2;

[0047] (3) Fix the lower part of the diagonal support 3 on the floor 2, and then fix the upper support point of the diagonal support 3 at the 2 / 3 height of the prefabricated external wall panel 1;

[0048] (4) Adjust the position of the prefabricated external hanging wall panel 1 (through the diagonal support 3 and the cushion block 6), install the reinforcement 4 at the place where the prefabricated external hanging w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com