Oilfield profile and drive control blocking system, method and slug composition for blocking

A technology of profile control and flood control, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of one-way breakthrough of water injection wells, low sweep coefficient, uneven benefit of oil wells, etc., and achieve reduction Pollution, EOR effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

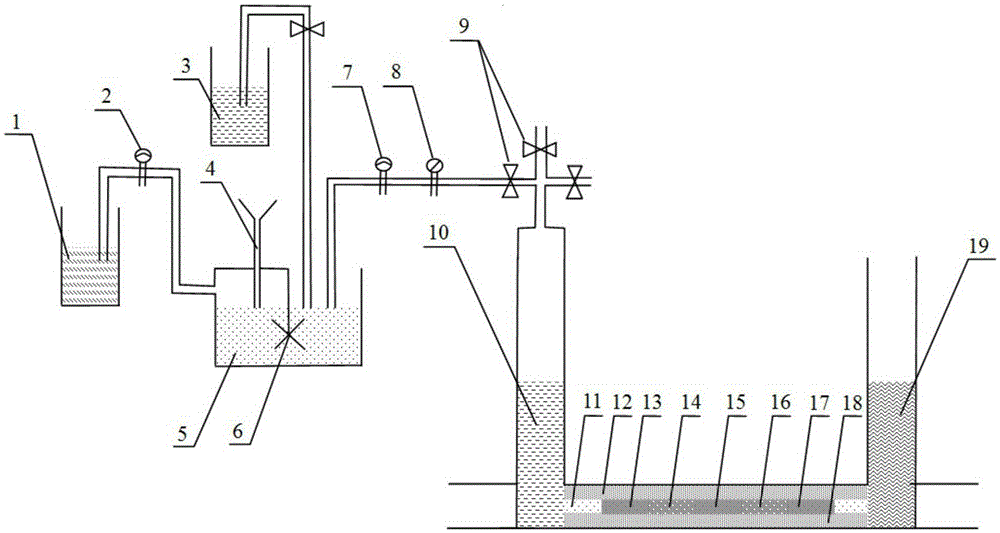

[0102] The method of using the above-mentioned oilfield profile control, flooding and plugging system to carry out oilfield profile control, flooding and plugging is specifically carried out according to the following steps:

[0103] Step 1, prepare for oilfield profile control, flooding and plugging, specifically follow the steps below:

[0104] First, inject the oily sludge cleaned from the oil tank station into the sludge pool 1;

[0105] Then, use clear water to carry out trial injection, the specific method is to inject clear water from the clear water tank 3 into the stirring tank 5, then directly inject the clear water into the formation, measure the injected clear water through the flow meter 7, and use the pressure gauge 8 to measure the formation pressure. Real-time monitoring, real-time understanding of pressure changes, providing reference for injection of plugging agent construction, so as to control the injection speed and lifting pressure value of each slug acco...

Embodiment 2

[0139] The method of using the above-mentioned oilfield profile control, flooding and plugging system to carry out oilfield profile control, flooding and plugging is specifically carried out according to the following steps:

[0140] Step 1, prepare for oilfield profile control, flooding and plugging, specifically follow the steps below:

[0141] First, inject the oily sludge cleaned from the oil tank station into the sludge pool 1;

[0142] Then, use clear water to carry out trial injection, the specific method is to inject clear water from the clear water tank 3 into the stirring tank 5, then directly inject the clear water into the formation, measure the injected clear water through the flow meter 7, and use the pressure gauge 8 to measure the formation pressure. Real-time monitoring, real-time understanding of pressure changes, providing reference for injection of plugging agent construction, so as to control the injection speed and lifting pressure value of each slug acco...

Embodiment 3

[0176] The method of using the above-mentioned oilfield profile control, flooding and plugging system to carry out oilfield profile control, flooding and plugging is specifically carried out according to the following steps:

[0177] Step 1, prepare for oilfield profile control, flooding and plugging, specifically follow the steps below:

[0178] First, inject the oily sludge cleaned from the oil tank station into the sludge pool 1;

[0179] Then, use clear water to carry out trial injection, the specific method is to inject clear water from the clear water tank 3 into the stirring tank 5, then directly inject the clear water into the formation, measure the injected clear water through the flow meter 7, and use the pressure gauge 8 to measure the formation pressure. Real-time monitoring, real-time understanding of pressure changes, providing reference for injection of plugging agent construction, so as to control the injection speed and lifting pressure value of each slug accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com