Wide temperature range laser based on hexagon plate strip structure

A slab structure and hexagonal technology, applied in the field of lasers, can solve the problem that the output power of all solid-state lasers is greatly affected by temperature, and achieve the effect of ensuring insensitivity, large output power, and high beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

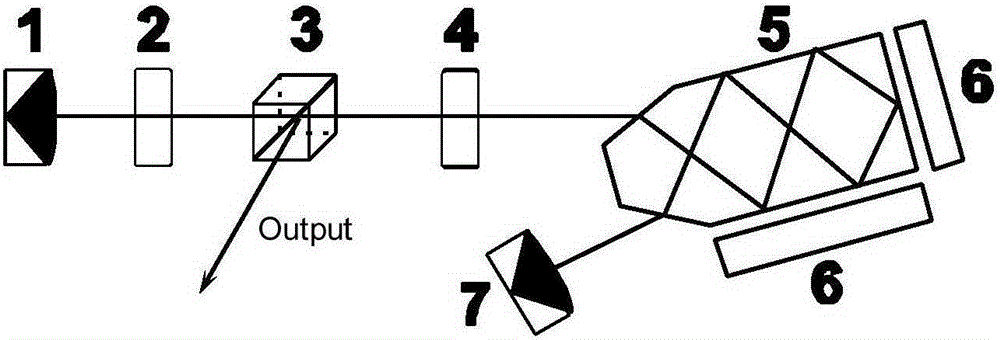

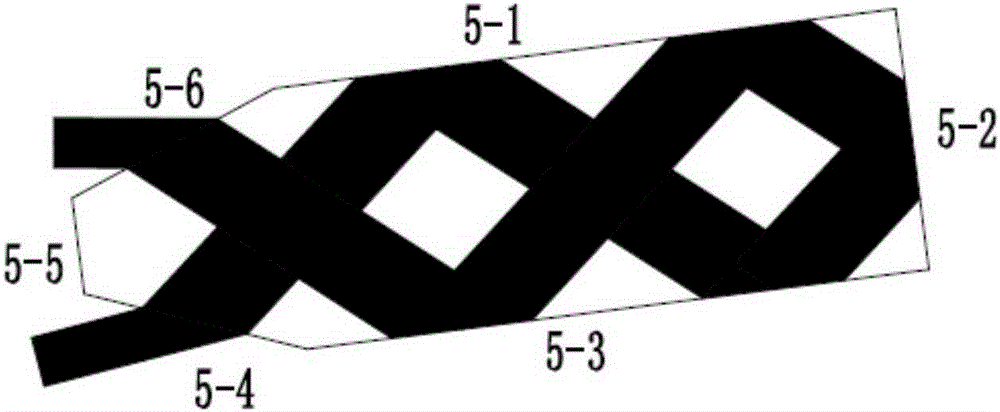

[0025] Such as figure 1 As shown, the present invention is based on a wide temperature laser embodiment 1 of a hexagonal slab structure, including a first Paul prism 1, a 0.57 wave plate 2, a polarizing beam splitter 3, a 1 / 4 wave plate 4, a laser gain medium 5, A high-power laser diode light source 6 and a second Paul prism 7. The high-power laser diode light source 6 is composed of several conduction-cooled laser diodes, arranged around the laser medium for providing pump light; the first Paul prism 1, 0.57 wave plate 2, polarization beam splitter 3, 1 / 4 wave plate 4, laser gain medium 5 and second Paul prism 7 are arranged in sequence to form a polarization coupling output resonant cavity, the output rate of the resonant cavity can be changed by rotating the 1 / 4 wave plate, the first Paul prism 1 and The second Paul prism 7 is placed orthogonally; the laser gain medium 5 is the Nd:YAG medium of the hexagonal slab structure, and the included angles between the optical axis ...

Embodiment 2

[0031] Such as Figure 4 As shown, it can be seen from the figure that the present invention is based on the wide temperature laser embodiment 2 of the hexagonal slab structure, including the first Paul prism 1, the 0.57 wave plate 2, the polarizing beam splitter 3, the 1 / 4 wave plate 4, the laser Gain medium 5, high-power laser diode light source 6, second Paul prism 7 and Pockels cell 8. The first Paul prism 1, the 0.57 wave plate 2, the Pockels cell 8, the polarization beam splitter 3, the 1 / 4 wave plate 4, the laser gain medium 5 and the second Paul prism 7 are arranged in sequence to form a polarization coupling output The resonant cavity can change the output rate of the resonant cavity by rotating the 1 / 4 wave plate, and the first Paul prism 1 and the second Paul prism 7 are orthogonally placed; the laser gain medium 5 is the Nd of the hexagonal slab structure: YAG medium, the angle between the optical axis and the incident surface and the outgoing surface of the slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com