Whole-course operation system and method for SCR denitration device of coal-fired power plant boiler

A technology of coal-fired power plants and DCS systems, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as excessive nitrogen oxide emissions, SCR denitrification devices cannot be put into operation, and boilers in coal-fired power plants cannot be solved. , to achieve the effect of realizing the whole process of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

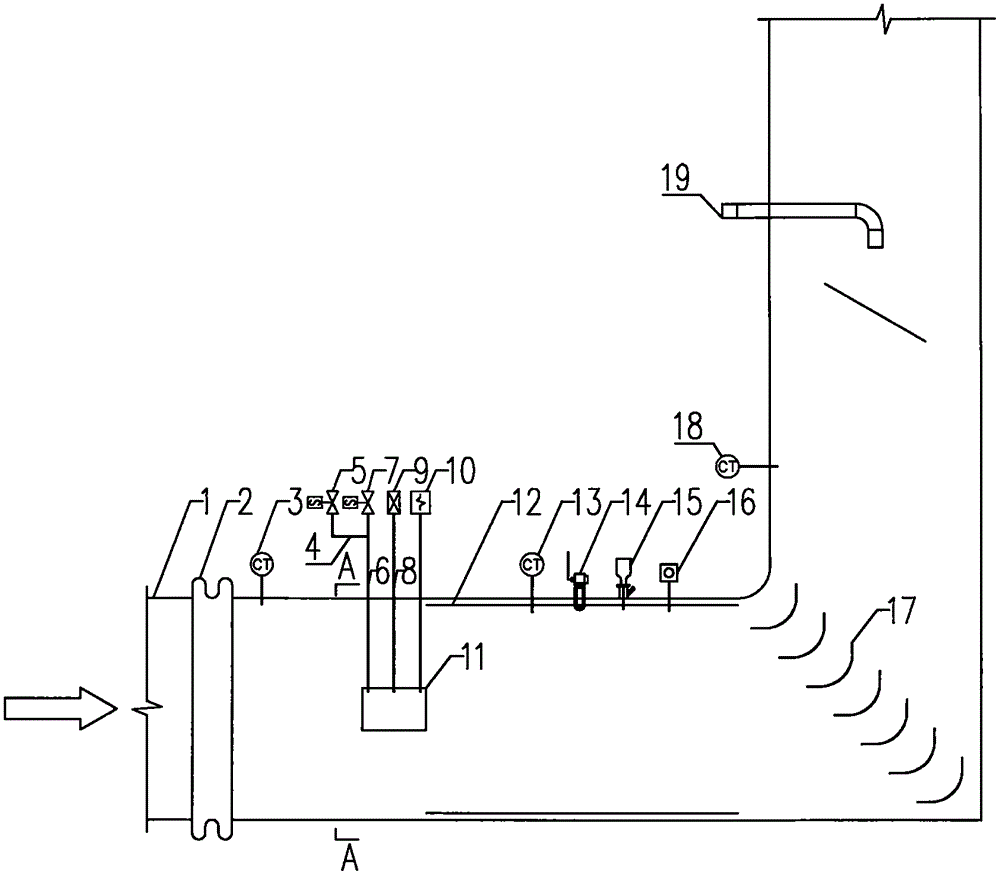

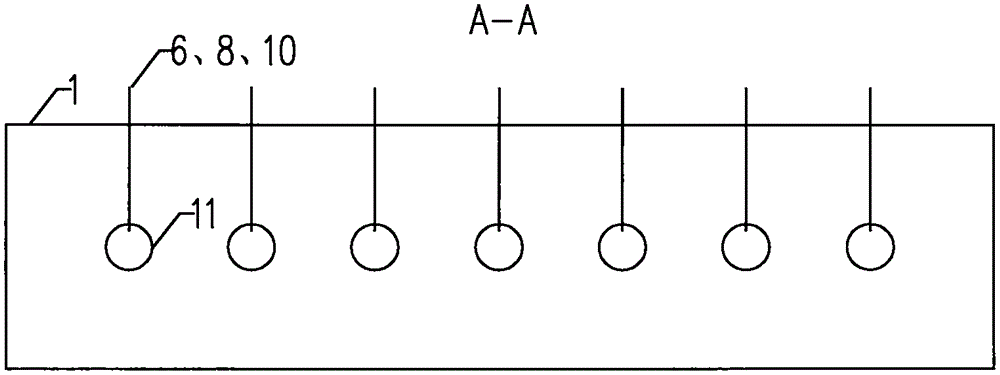

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 .

[0026] Such as figure 1 As shown, on the denitrification inlet flue 1, the expansion joints 2 of the denitrification inlet flue, multiple sets of flue gas heater systems arranged in parallel, heat insulation guards 12, flow guide baffles 17, and ammonia injection pipes are arranged in sequence along the flue gas flow direction. 19.

[0027] Such as figure 2 As shown, the number of the above-mentioned multiple sets of flue gas heater systems is determined according to the physical heat and heat balance formula. In this embodiment, the number of flue gas heater systems arranged in the denitrification inlet flue 1 is 7 sets.

[0028] The above-mentioned flue gas heater system includes: flue gas temperature measuring point 3 at the denitrification inlet, flue gas heater compressed air pipe 4, flue gas heater oil gun compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com