Micro-gas ignition combustion-supporting combustion device

A combustion device, ignition and combustion-supporting technology, which is applied in the direction of burning with various fuels, burning with block fuels and gaseous fuels, burning with liquid fuels and gaseous fuels, etc., and can solve the problem of short life of the cathode and easy burning of the burner nozzle No damage, pollution denitrification catalyst, desulfurization slurry and other problems, to achieve the effect of strengthening heat and mass exchange process, fast flame propagation speed, and reducing fuel cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

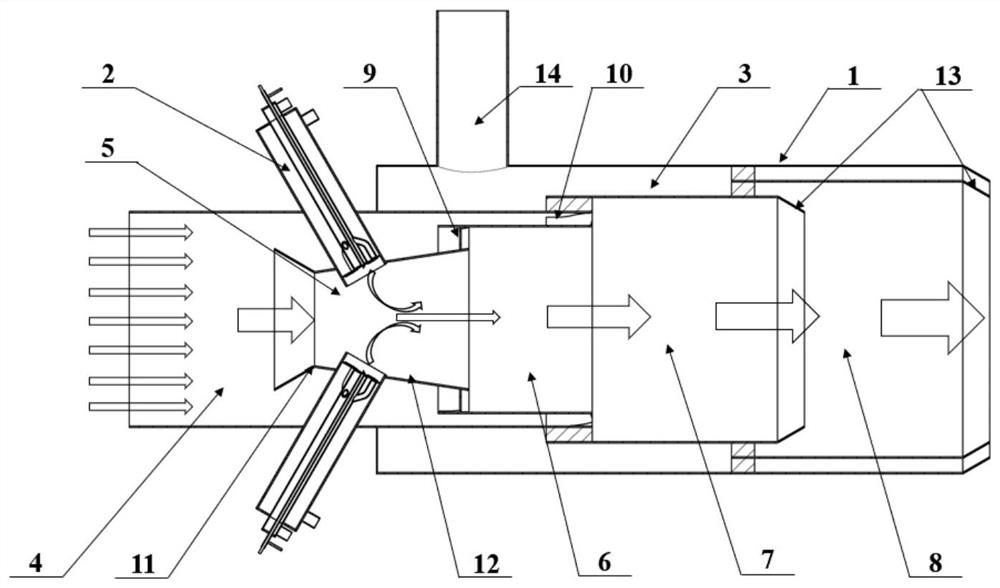

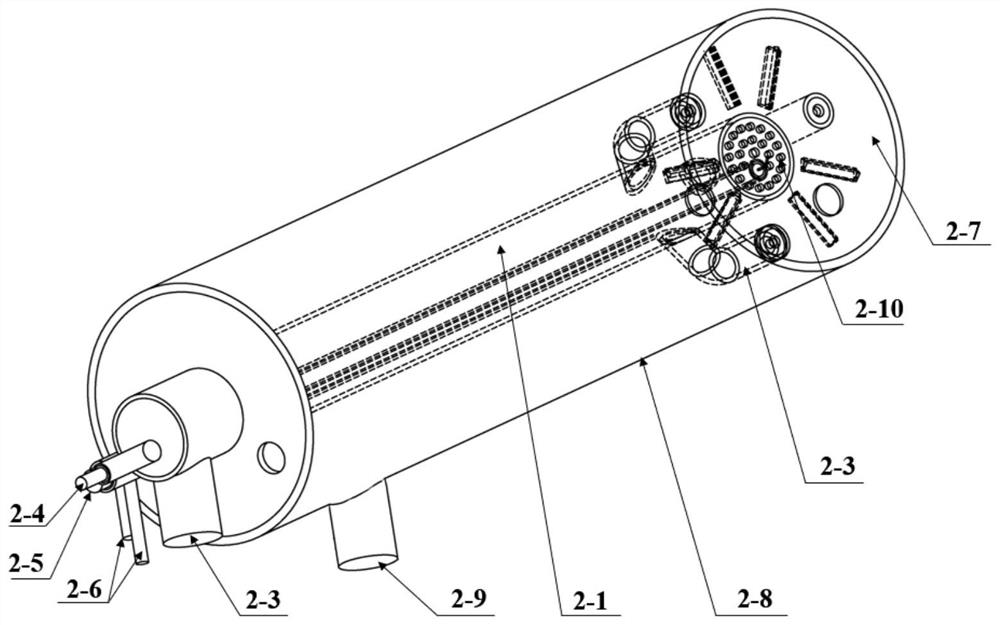

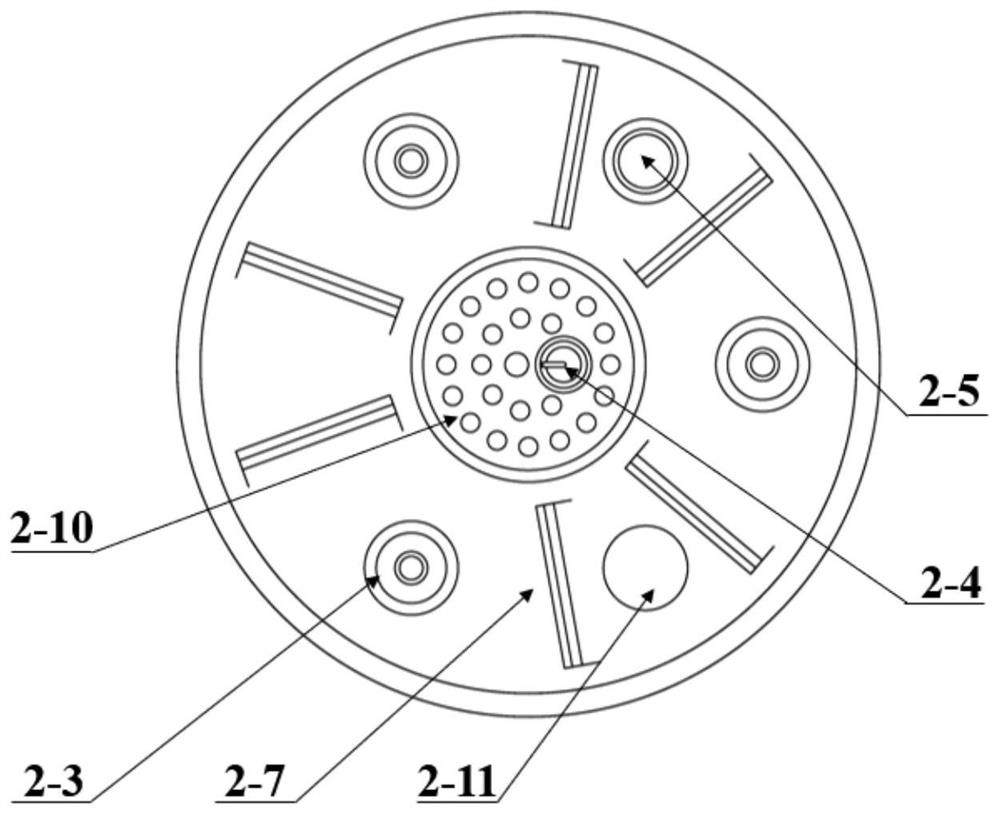

[0028] refer to figure 1 , figure 2 and image 3 , the micro-gas ignition and combustion-supporting combustion device of the present invention includes a pulverized coal combustion device 1, a film cooling wind device 3 and several natural gas combustion devices 2; the pulverized coal combustion device 1 includes a primary air powder pipe 4, a pulverized coal secondary combustion chamber 7. Pulverized coal tertiary combustion chamber 8, pulverized coal pre-combustion chamber 5, pulverized coal primary combustion chamber 6; pulverized coal pre-combustion chamber 5 is a structure that shrinks first and then expands, and pulverized coal pre-combustion chamber 5 includes a first hollow circular platform 11 And the second hollow round table 12, the bottom of the first hollow round table 11 is facing the incoming flow direction of the primary wind powder pipe 4, the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com