Method for preparing catalyst capable of performing simultaneous desulfurization and denitrification on flue gas

A desulfurization and denitrification, catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of temperature reduction, catalytic activity reduction, etc., to achieve the effect of enhanced adsorption capacity and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、10

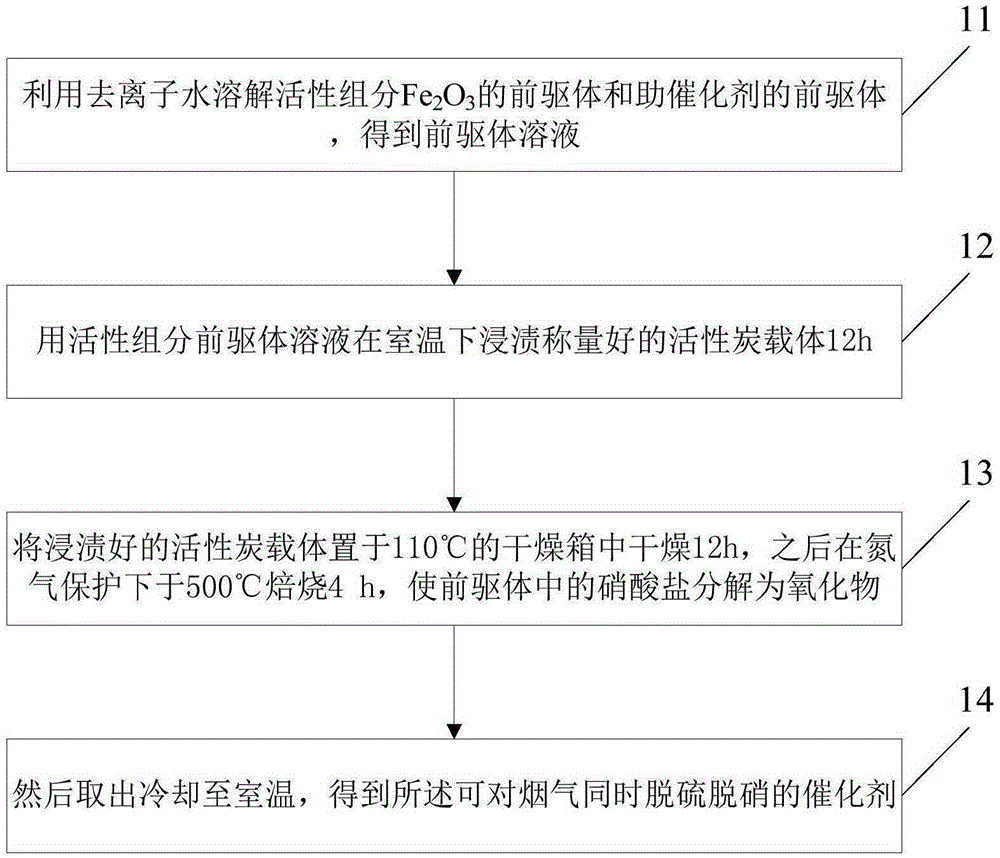

[0040] Example 1, 10% Fe 2 o 3 2%Y 2 o 3 / AC

[0041] First, weigh 20-40 mesh AC500g and put it in a glass container, add the prepared 10% HNO 3 , so that AC can be impregnated excessively. After impregnating for 12h, wash with deionized water until neutral, dry in a drying oven at 110°C for 12h, take it out and cool to room temperature, and set aside.

[0042] Then according to the loading capacity of the active component of the catalyst made and cocatalyst, the Fe(NO of 2.5299g 3 ) 3 9H 2 O, 0.3393g of Y (NO 3 ) 3 ·6H 2 0, add 7ml deionized water to be mixed with mixed solution;

[0043] Accurately weigh 5.0000g of pretreated AC, impregnate it into the prepared mixed solution, and impregnate it at room temperature for 12 hours. After obtaining the impregnated activated carbon, place it in a drying oven at 110°C for 12 hours, and then place it in a nitrogen-protected tube. Roasted at 500°C for 4 hours in a type roaster, then took it out and cooled to room temperatu...

Embodiment 2、10

[0045] Example 2, 10% Fe 2 o 3 2%La 2 o 3 / AC

[0046] First, weigh 20-40 mesh AC500g and put it in a glass container, add the prepared 10% HNO 3, so that AC can be impregnated excessively. After impregnating for 12h, wash with deionized water until neutral, dry in a drying oven at 110°C for 12h, take it out and cool to room temperature, and set aside.

[0047] Then according to the loading capacity of the active component of the catalyst made and cocatalyst, the Fe(NO of 2.5299g 3 ) 3 9H 2 O, 0.2658g of La(NO 3 ) 3 ·6H 2 0, add 7ml deionized water to be mixed with mixed solution;

[0048] Accurately weigh 5.0000g of the pretreated AC, impregnate it into the prepared mixed solution, and impregnate it at room temperature for 12 hours to obtain the impregnated activated carbon, then dry it in a drying oven at 110°C for 12 hours, and then place it in a tube type with nitrogen protection. Roasting at 500° C. for 4 hours in a roasting furnace, and then taking it out and ...

Embodiment 3、10

[0050] Example 3, 10% Fe 2 o 3 2%CeO 2 / AC

[0051] First, weigh 20-40 mesh AC500g and put it in a glass container, add the prepared 10% HNO 3 , so that AC can be impregnated excessively. After impregnating for 12h, wash with deionized water until neutral, dry in a drying oven at 110°C for 12h, take it out and cool to room temperature, and set aside.

[0052] Then according to the loading capacity of the active component of the catalyst made and cocatalyst, the Fe(NO of 2.5299g 3 ) 3 9H 2 O, 0.2523g of Ce(NO 3 ) 3 ·6H 2 0, add 7ml deionized water to be mixed with mixed solution;

[0053] Accurately weigh 5.0000g of pretreated AC, impregnate it into the prepared mixed solution, and impregnate it at room temperature for 12 hours. After obtaining the impregnated activated carbon, dry it in a drying oven at 110°C for 12 hours, and then place it in a tube protected by nitrogen. Roasted at 500° C. for 4 hours in a type calciner, and then taken out and cooled to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com