Multiple-connection-blade precision casting method

A technology of precision casting and concatenation, applied in the direction of casting molding equipment, molds, mold components, etc., can solve problems such as low pass rate, crack structure, looseness, etc., and achieve cracks and looseness, consistent cooling rate, cooling uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The concatenated blade precision casting method of this embodiment is carried out according to the following steps:

[0024] (1) Use a high-pressure press to press the multi-joint blade wax mold, keep the temperature of the wax storage tank at 80°C, and the temperature of the wax injection nozzle at 73°C, inject the wax liquid into the multi-joint blade ceramic core, and the injection pressure is 2.0MPa , the mold clamping pressure is 5.0MPa, and the holding time is 30s to obtain the concatenated blade wax mold;

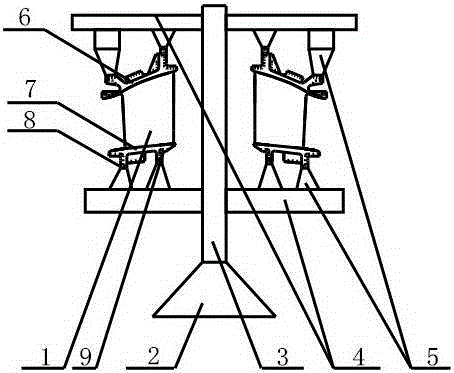

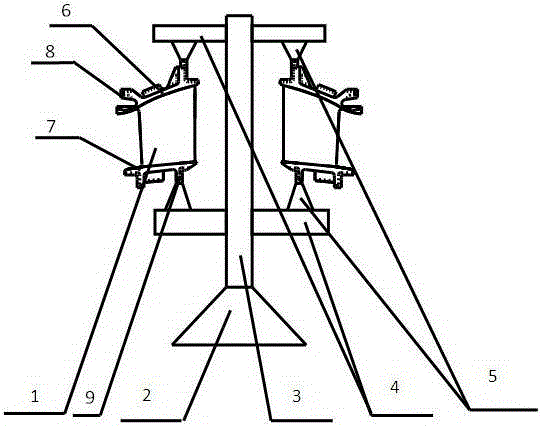

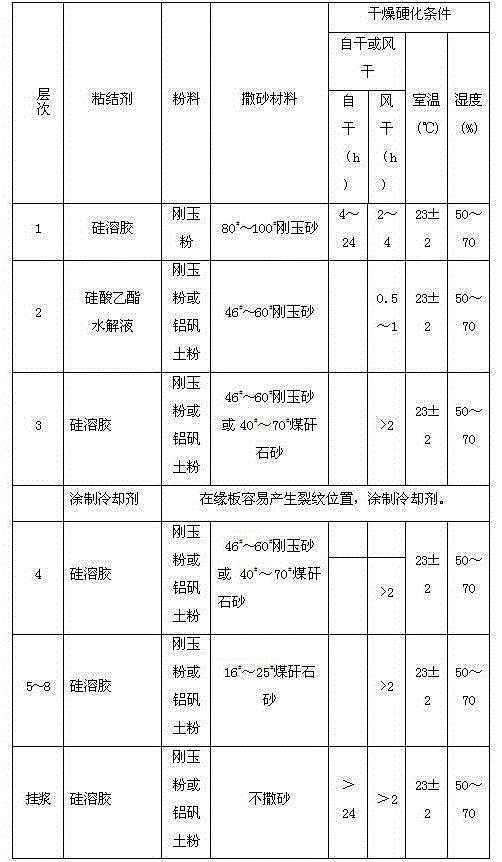

[0025] (2) From the inside to the outside, three layers of refractory materials are coated on the surface of the concatenated blade wax model in sequence, and after the third layer of refractory material is coated, at the positions of the large edge plate 6 and the small edge plate 7 of the concatenated blade Coating coolant, the coolant is made by mixing silica sol, corundum powder and iron pellets according to the weight ratio of 1:5:8, and then continue to ...

Embodiment 2

[0029] (1) Use a high-pressure press to press the multi-joint blade wax model, keep the temperature of the wax storage tank at 80°C, and the temperature of the wax injection nozzle at 71°C, inject the wax liquid into the multi-joint blade ceramic core, and the injection pressure is 2.0MPa , the clamping pressure is 5.0MPa, and the holding time is 40s to obtain the concatenated blade wax mold;

[0030] (2) From the inside to the outside, three layers of refractory materials are coated on the surface of the concatenated blade wax model in sequence, and after the third layer of refractory material is coated, at the positions of the large edge plate 6 and the small edge plate 7 of the concatenated blade Coating coolant, the coolant is made by mixing silica sol, corundum powder and iron pellets according to the weight ratio of 1:6:5, and then continue to coat the fourth to eighth layers of refractory materials, and finally pass through Drying and hardening, dewaxing, and then roast...

Embodiment 3

[0034] (1) Use a high-pressure press to press the multi-joint blade wax mold, keep the temperature of the wax storage tank at 80°C, and the temperature of the wax injection nozzle at 75°C, inject the wax liquid into the multi-joint blade ceramic core, and the injection pressure is 2.0MPa , the mold clamping pressure is 5.0MPa, and the holding time is 50s to obtain the concatenated blade wax mold;

[0035] (2) From the inside to the outside, three layers of refractory materials are coated on the surface of the concatenated blade wax model in sequence, and after the third layer of refractory material is coated, at the positions of the large edge plate 6 and the small edge plate 7 of the concatenated blade Coating coolant, the coolant is made by mixing silica sol, corundum powder and iron pellets according to the weight ratio of 1:4:6, and then continue to coat the fourth to eighth layers of refractory materials, and finally pass through Drying and hardening, dewaxing, and then r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com