Automatic welding machine for boiler inner circular seam submerged arc

An automatic welding machine and inner ring seam technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult to guarantee welding quality, long time-consuming, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with embodiment.

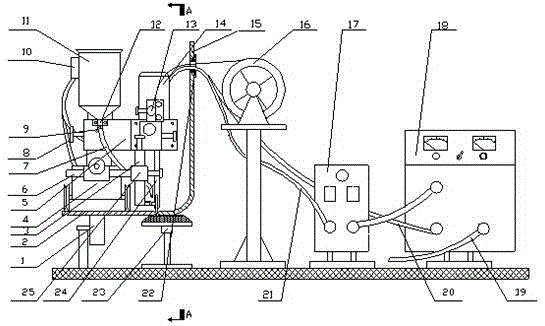

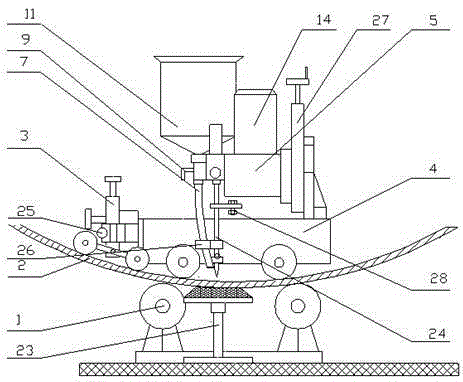

[0012] See figure 1 and figure 2 , a boiler inner ring seam submerged arc automatic welding machine is mainly composed of a welding trolley, a welding power source 18, an electric control box 17, a wire feeding reel 16, a flux tray 23, a welding handle 20 and a control line 21. Several supporting rotary tires 1 are installed on the ground, and the boiler shell 2 is placed on the supporting rotary tires 1 . The boiler shell 2 and the drum head 15 form a circular weld, and an aperture is opened on the drum head 15, and an insulating sleeve 22 is placed on the aperture. The welding trolley is put into the boiler shell 2, and the welding trolley includes a welding torch 24, a wire feeder 14, a flux hopper 11, a horizontal adjustment slider 5, a longitudinal adjustment slider 27, a welding seam tracking device 3 and a walking trolley 4; a walking trolley 4 The seam tracking devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com