A flat rolling tool lubricated by vacuum pumping

A technology of vacuum pumping and rolling tools, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of increased local stress on the surface of parts, affecting processing quality, and small rolling allowance of rolling tools and other problems, to achieve the effect of high machining accuracy and reducing the hidden danger of burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

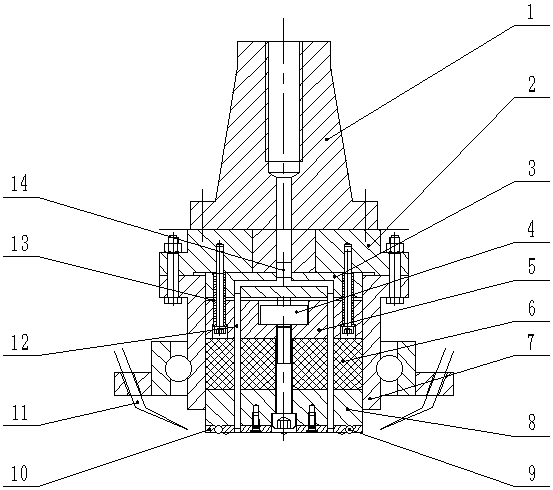

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as figure 1 As shown, a flat rolling tool that is lubricated by vacuum pumping includes a handle part and a tool body, and the handle part includes a handle 1 and a handle connecting block 2, and the handle 1 and the knife The handle connection block 2 is connected, the tool body includes a tool connection cylinder 7 and a ball assembly located at the bottom of the tool connection cylinder 7, the knife handle connection block 2 is connected to the upper end of the tool connection cylinder 7, and the tool body also includes Bearing plate 3, force sensor 4, sensor fixing seat 5 and Youli glue 6, described tool connecting cylinder 7 arranges bearing plate 3, force sensor 4, sensor fixing seat 5, Youli glue 6 and Ball 9 assembly, the handle connecting block 2 is connected with the bearing plate 3, the bearing plate 3 and the sensor holder 5 are in clearance fit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com