Automatic conveying system used between calendaring process and drying process of fiberboards

An automatic conveying, fiberboard technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing drying energy consumption, slow water loss, and accelerated heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

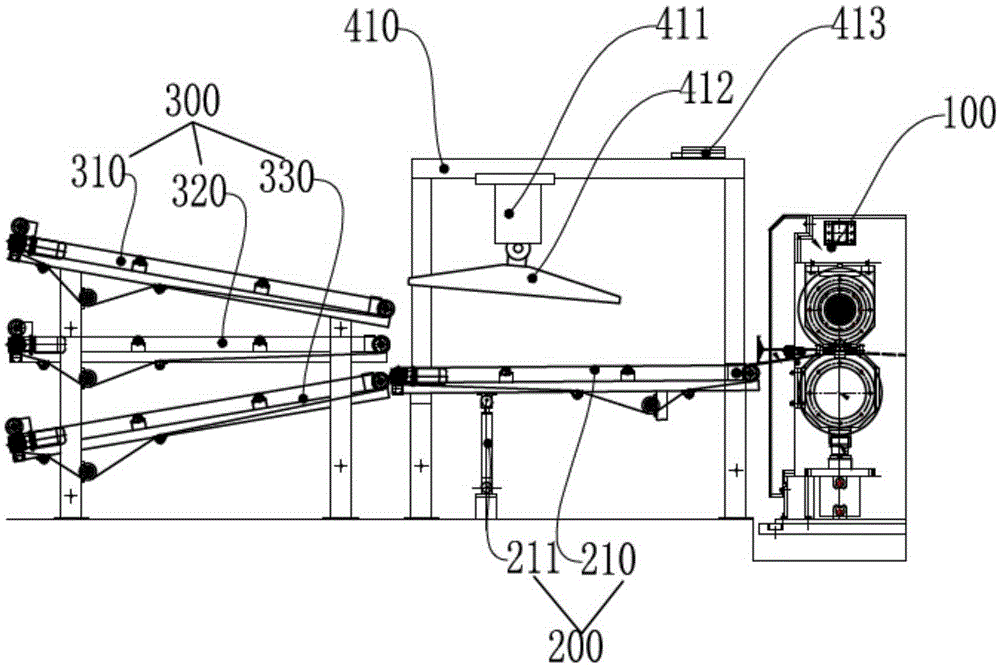

[0017] Such as figure 1 As shown, this application provides an automatic conveying system for high-density fiberboard between water pressing and drying processes, which is suitable for the fiberboard production industry and can optimize the structure of the existing fiberboard production line, thereby improving the water pressure and conveying of fiberboard And drying efficiency, and can significantly improve the space utilization rate of the enterprise workshop, reduce the labor demand of the enterprise and improve the economic benefits of the enterprise.

[0018] The above-mentioned automatic conveying system for fiberboard calendering and drying processes includes a semi-dry calender 100 connected in sequence, a first conveying mechanism 200 and a second conveying mechanism 300; the first conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com