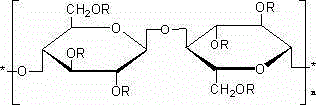

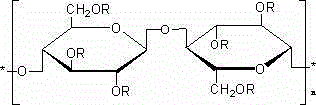

Preparation methods of hydroxypropyl methyl cellulose-soybean protein copolymer and its plant capsule

A technology of hydroxypropyl methylcellulose and soybean protein, which is applied in the direction of capsule delivery and non-active ingredients of polymer compounds, can solve the problems of not being widely used, high cost, and slow gelation speed, etc., and achieve a solution The effect of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

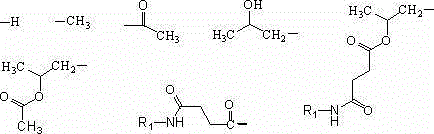

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 10g of hypromellose succinate (degree of acylation: 12.5), 10g of soybean protein isolate, and 1.0g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride in 100mL deionized water, then add 0.5g 4-dimethylaminopyridine, stir and react at room temperature overnight; after concentrating the reaction solution under reduced pressure, add an appropriate amount of ethyl acetate to precipitate the product, wash and filter the product, and vacuum dry to obtain the target product. 91%.

Embodiment 2

[0031] Dissolve 5g of hypromellose succinate (degree of acylation: 12.5), 10g of soybean protein isolate, and 1.0g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride in 100mL deionized water, then add 0.5g 4-dimethylaminopyridine, stir and react at room temperature overnight; after concentrating the reaction solution under reduced pressure, add an appropriate amount of ethyl acetate to precipitate the product, wash and filter the product, and vacuum dry to obtain the target product. 92%.

Embodiment 3

[0033] Dissolve 10g of hypromellose succinate (degree of acylation: 18.3), 10g of soybean protein isolate, and 1.0g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride in 100mL of deionized water, then add 0.5g of N-hydroxysuccinimide, and stir at room temperature overnight; after concentrating the reaction solution under reduced pressure, add an appropriate amount of ethyl acetate to precipitate the product, wash and filter the product, and vacuum dry to obtain the target product. The rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com