Dry distillation furnace and combustion chamber of dry distillation furnace

A technology of combustion chamber and retort furnace, which is applied in the field of coal retort distillation, which can solve the problems of not being too thick, poor stability of partition walls, and low output of retort furnace, and achieve the effects of improving strength and stability, uniform heating, and improving uniformity of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

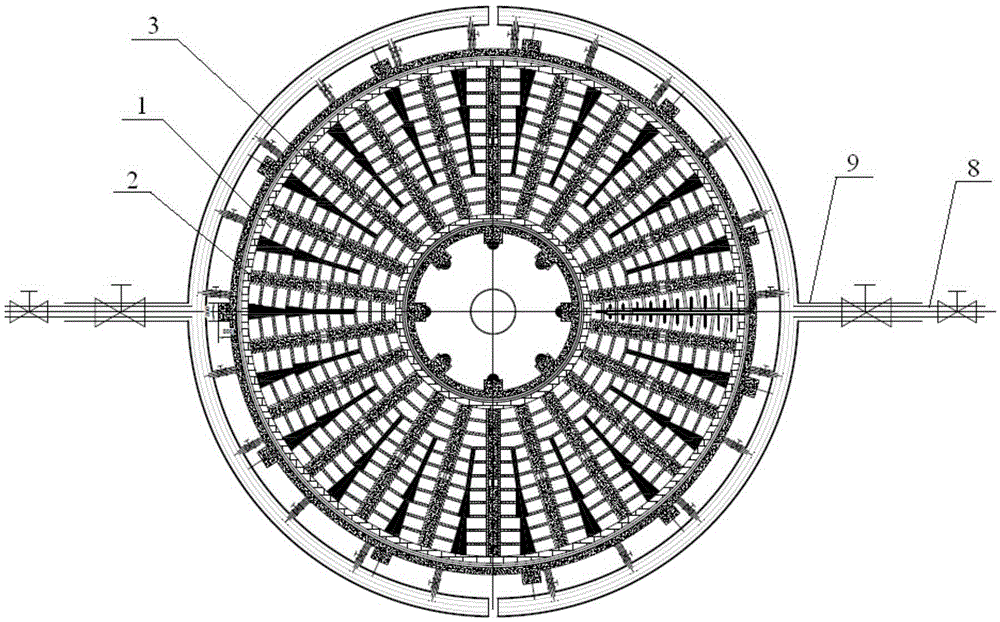

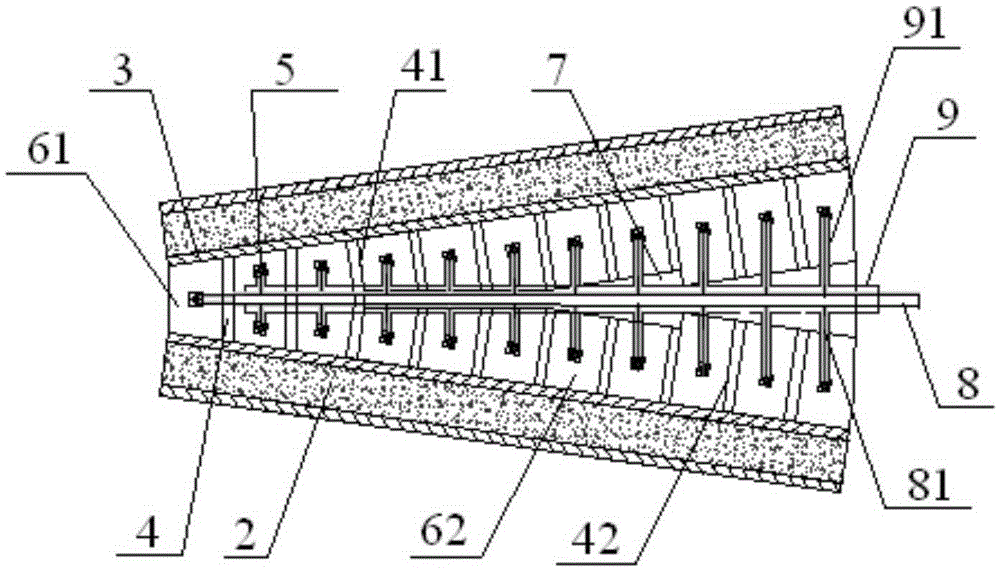

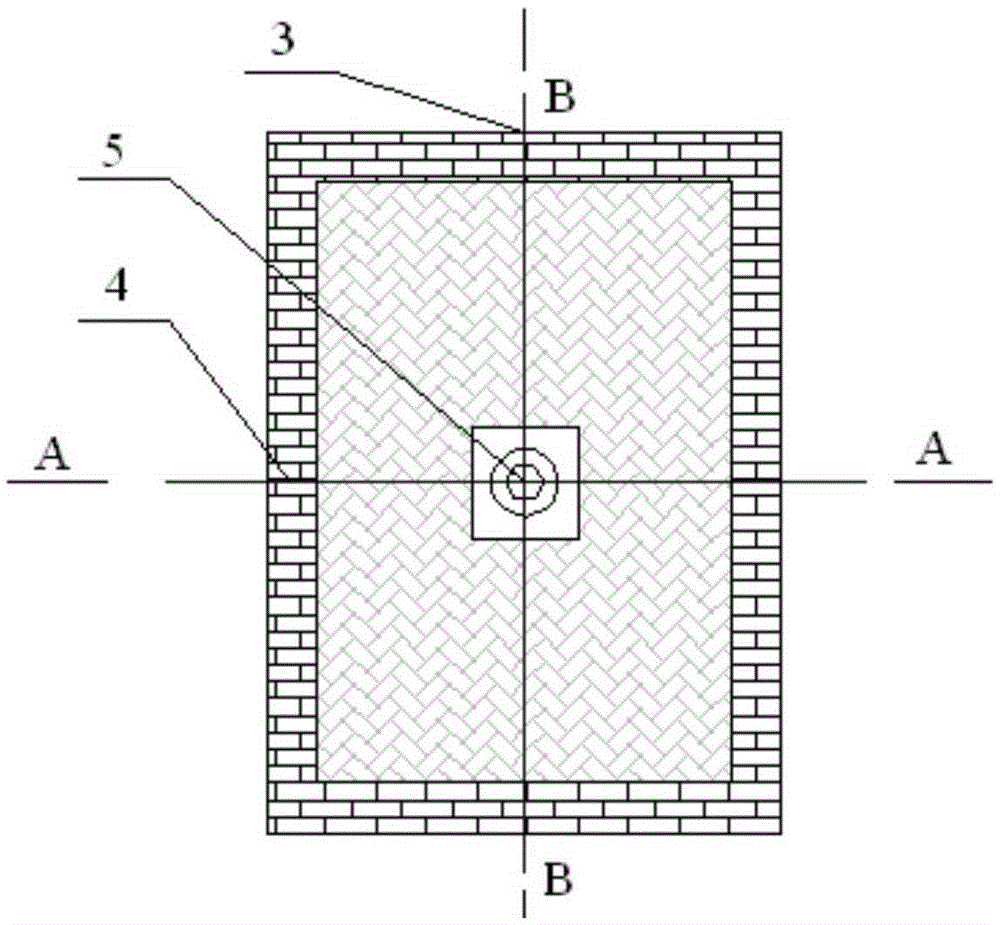

[0030] The core of the present invention is to provide a dry distillation furnace and its combustion chamber, which can improve the heating uniformity of the combustion chamber to the carbonization chamber, so as to improve the heating uniformity of the coal seam in the carbonization chamber, and at the same time improve the combustion chamber of the dry distillation furnace and the carbonization chamber. the stability of the partition walls.

[0031] The dry distillation furnace and its combustion chamber of the present invention will be described in detail below with reference to the accompanying drawings, so that those skilled in the art can accurately understand the technical solutions of the present invention.

[0032] The inner and outer, upper and lower, circumferential, axial and radial directions described in this article are all based on the retort furnace. Down, the direction away from the ground is up; the retort is set as a cylindrical structure, then the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com