TC11 titanium alloy and technique for optimizing performance of TC11 titanium alloy

A TC11, titanium alloy technology, applied in the field of titanium alloys, can solve the problems of poor welding performance, poor formability, high price, etc., and achieve the effect of good metallographic structure and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A TC11 titanium alloy, the weight percent of its raw material components is: Al: 4.4-5.7%, Mo: 4.4-5.7%, V: 4.4-5.7%, Cr: 0.5-1.5%, Fe: 0.5-1.5%, C <0.1%, Zr:<0.3%, Si<0.15%, O<0.18%, N<0.05%, H<0.015%, and the rest is Ti. The raw materials are synthesized into TC11 alloy according to the conventional method, and then the alloy is combined with 700- Keep the temperature at 950°C for 1 hour, and then cool the alloy with water, air or in a furnace to below 350°C. The holding temperature is: 900°C, and the cooling method is: cooling down to below 350°C in the furnace.

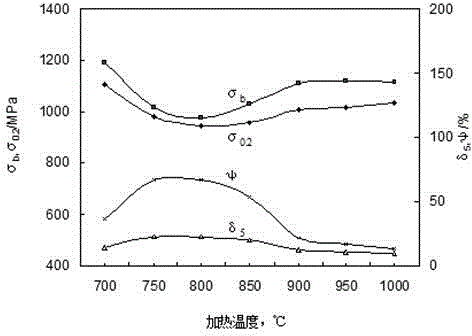

[0012] The results of the tensile test show that the tensile strength of the TC11 titanium alloy under water-cooling conditions shows an obvious downward trend with the increase of the heating temperature, and can be roughly divided into three stages according to the speed of the σb decrease: the temperature range of 700-800 °C decreases the fastest , dropped rapidly from 1100MPa to about 900MPa; σb stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com