Brushing and throwing type snow removal trolley for track snow removal

A trolley and brush-throwing technology, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of low snow shoveling speed, no strict requirements for vehicle running tracks, and affecting the normal connection of trains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

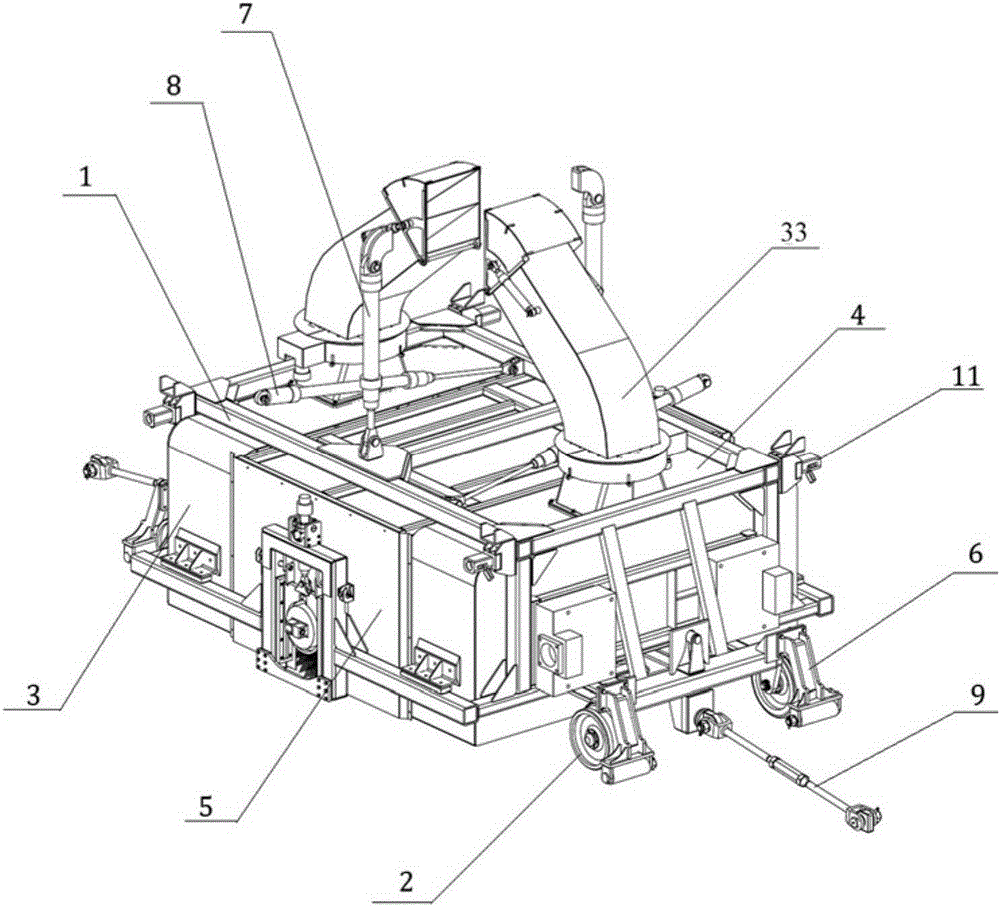

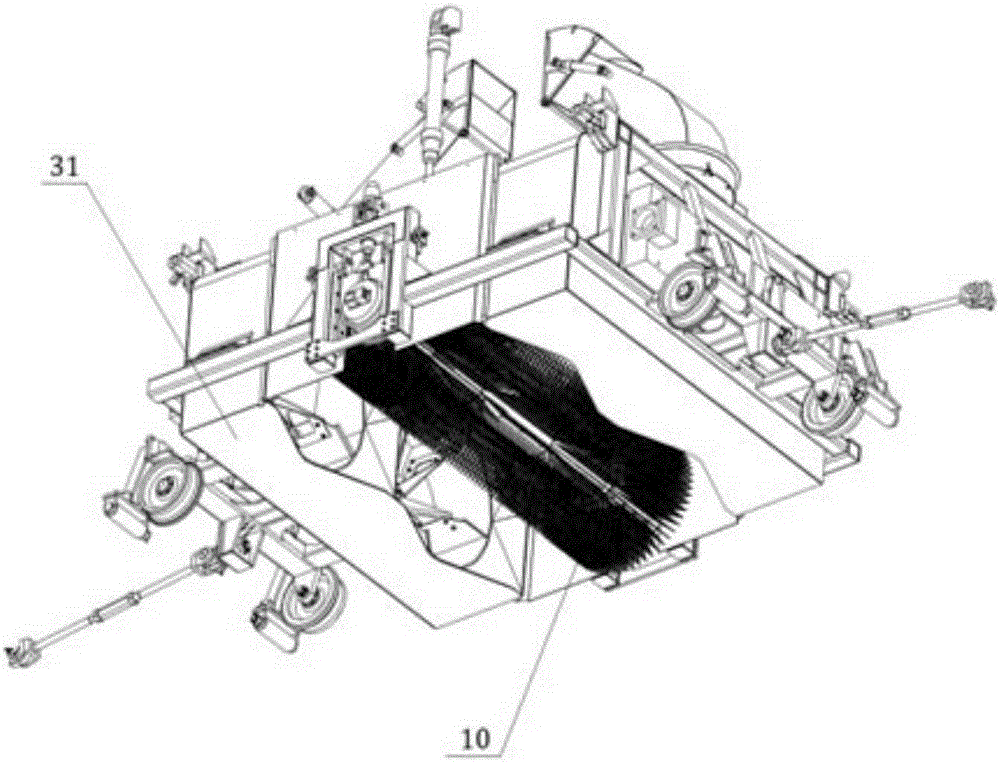

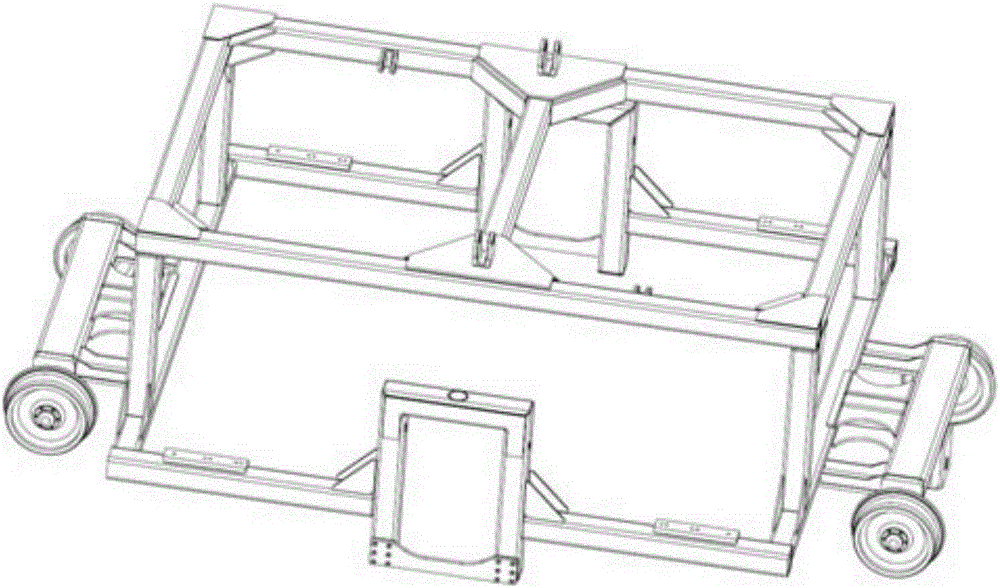

[0088] Example 1.1 : Brush-throwing snow removal trolley for track snow removal Figure 1-Figure 7 It is a schematic diagram of the components of a preferred embodiment of the brush-throwing snow removal trolley for track snow removal according to the first aspect of the present invention. The brush-throwing snow removal trolley provided in this embodiment includes a snow blower frame 1, and the snow blower machine The front and rear sides of the frame 1 are respectively provided with two working wheels, which are used to fall on the rails and roll during operation. Two snow blowers 3 are symmetrically installed in the frame 1 of the snow blower to clean the snow on the surface of the track. And throw the accumulated snow outside the track, the snow throwing blower 3 includes a rectangular fan casing 31 with an opening, the openings of the blower casings 31 of the two snow throwing blowers 3 are relatively arranged, and the opposite side of the opening of each snow throwing b...

Embodiment 12

[0113] Example 1.2 : brush throwing type snow removal dolly, with embodiment 1.1, difference is: the outer diameter of bristle on both sides of described dumbbell-shaped rolling brush 10 is 1150mm.

Embodiment 13

[0114] Example 1.3 : brush throwing type snow removal dolly, with embodiment 1.1, difference is: the outer diameter of bristle on both sides of described dumbbell-shaped rolling brush 10 is 1050mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com