Slagging promoting device for ultra-thick clay layer positive-cycle cast-in-place pile and construction method of slagging promoting device

A construction method and clay layer technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor slag discharge ability and reduce the thickness of clay drilling slag deposition, and achieve simple production, improved slag discharge ability and drilling Improve efficiency and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

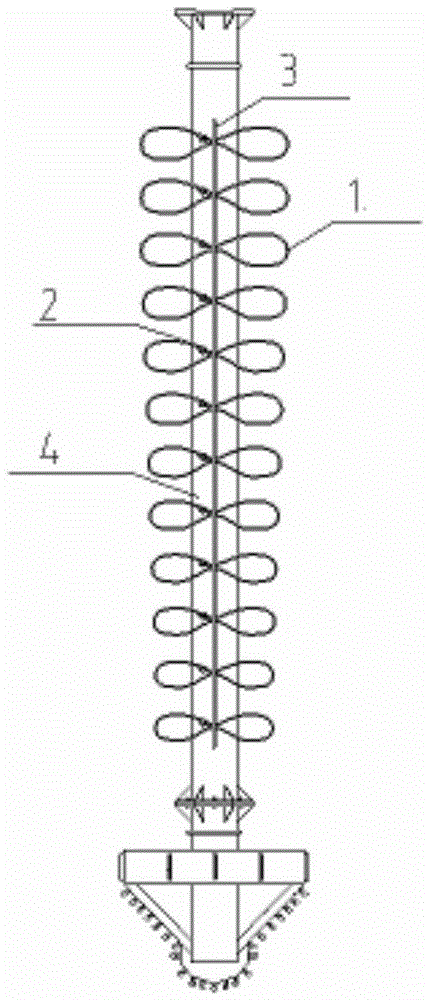

[0026] Such as figure 1 and 2 As shown, a pile foundation project adopts positive circulation construction technology, the pile length is 65m, and the pile diameter is 700mm. According to the engineering geological report, the pile will pass through a clay layer as thick as nearly 50m. During the drilling process, the footage was slow or even non-existent, which greatly affected the construction progress of the project, so it was decided to use the super-thick clay layer positive circulation cast-in-situ pile slag discharge promotion device and its construction method to speed up the construction progress and save money. Engineering construction cost.

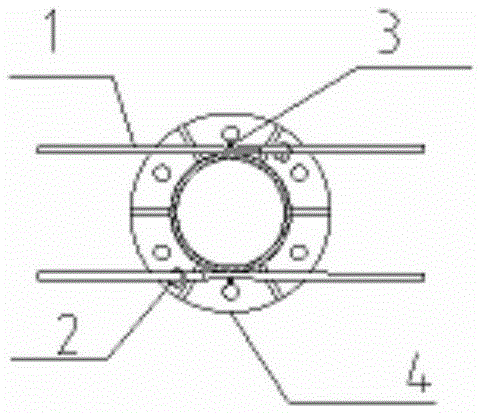

[0027] A slag removal promotion device for super-thick clay layer positive circulation cast-in-situ piles, which includes crushing wire rope bundles 1, wire rope clips 2, fixed bead 3 and drill pipe 4, using the high-speed rotation of the drill pipe to drive the crushing of steel wire rope bundles, thereby Clay drilling slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com