Conductive structure and integrated circuit assembly

A technology of conductive structures and devices, applied in the direction of electric solid devices, semiconductor devices, circuits, etc., can solve the problems of increased deposition thickness, increased manufacturing cost, increased metal layer thickness, etc., and achieves reduced thickness and reduced manufacturing cost. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

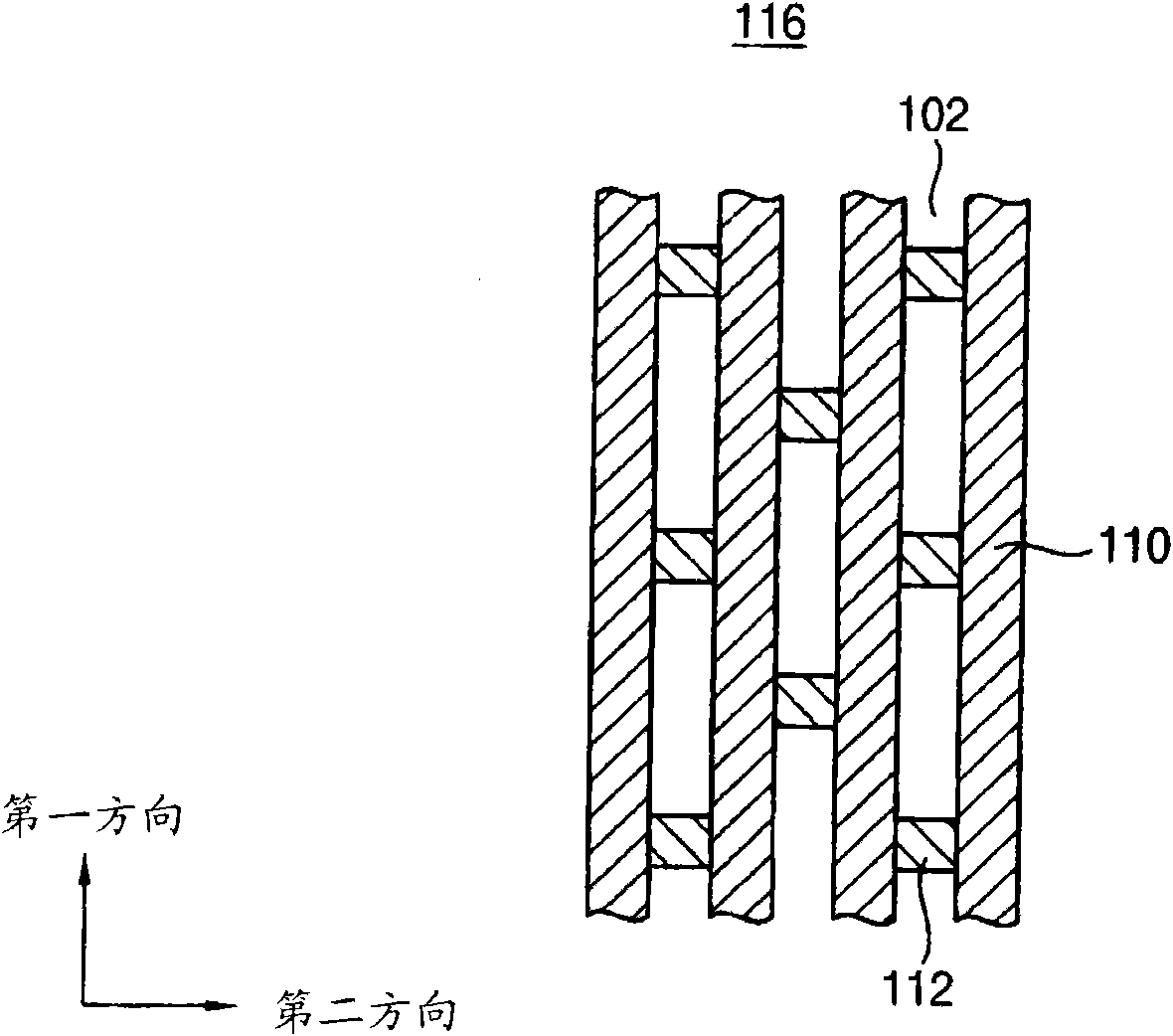

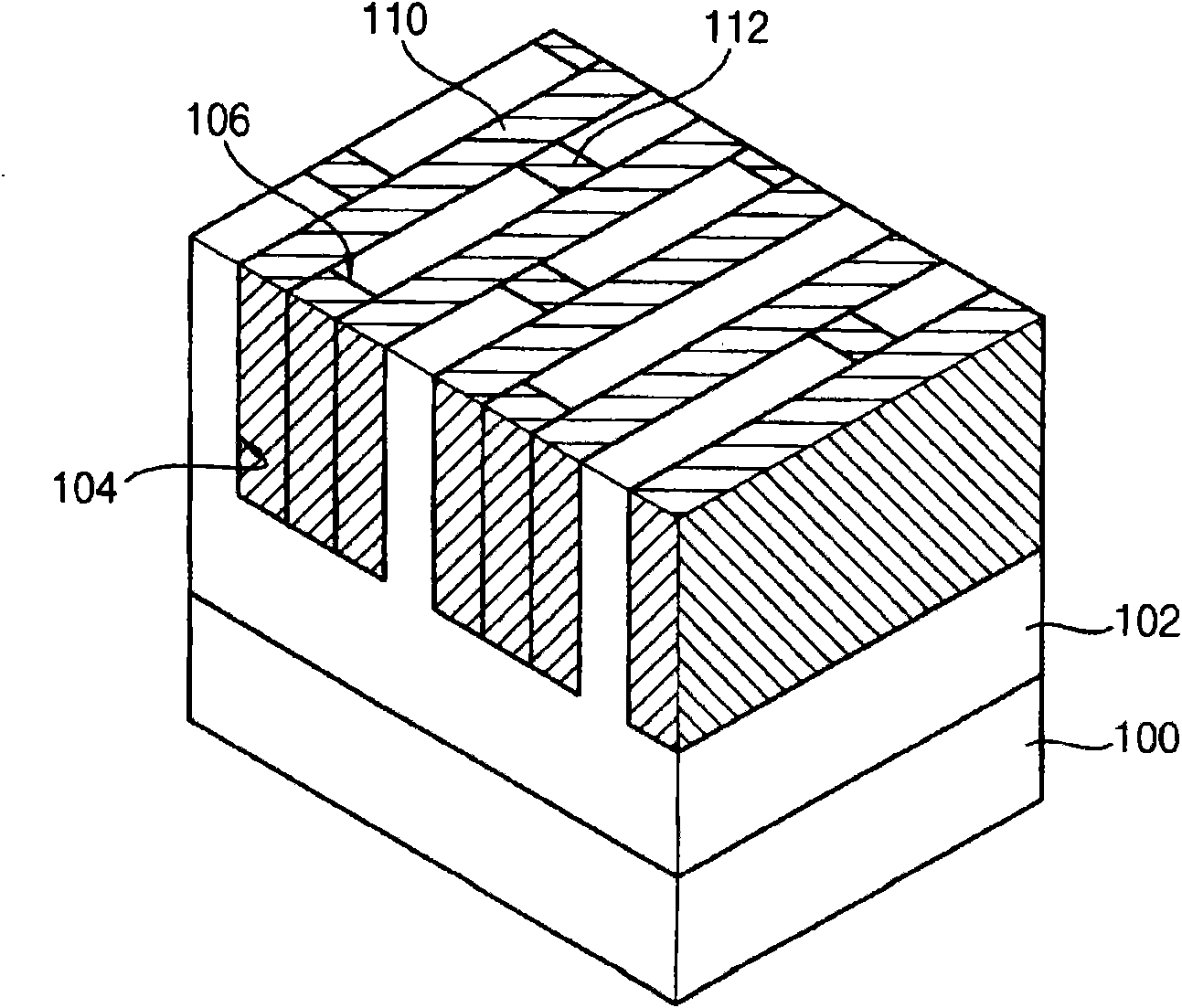

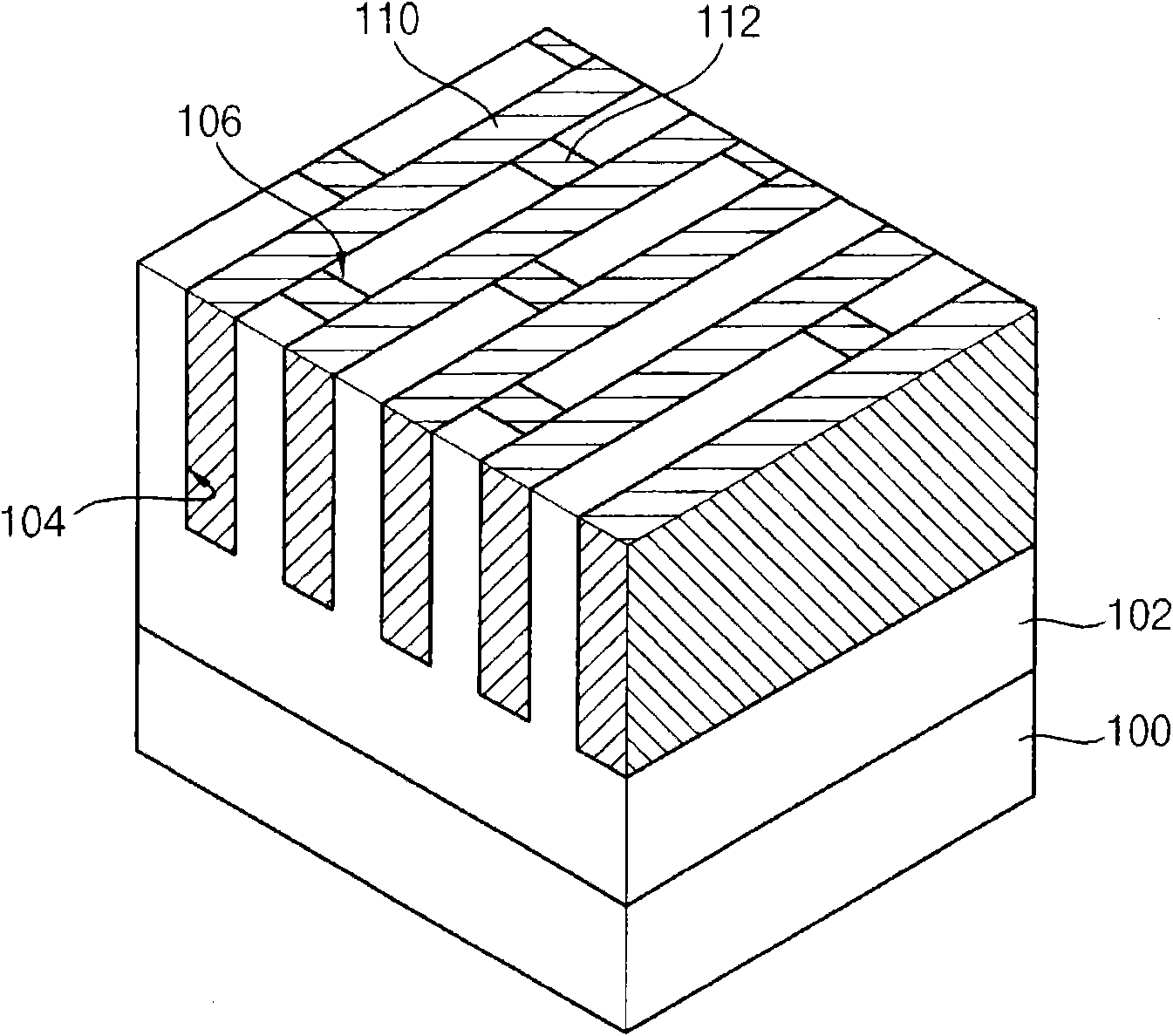

[0062] figure 1 is a plan view illustrating a conductive pattern structure according to an exemplary embodiment. figure 2 is a perspective view showing figure 1 The conductive pattern structure shown. image 3 is another perspective view showing figure 1 The conductive pattern structure shown.

[0063] cable in figure 2 is shown in cross-section in the perspective view, however, the connecting lines are not in the image 3 The cross-section in the perspective view is shown.

[0064] refer to Figure 1 to Figure 3 The conductive pattern structure 116 may include a mold layer 102 formed on the substrate 100 using an insulating material. A plurality of first grooves 104 may be formed at the mold layer 102 parallel to each other. A plurality of second trenches 106 may be formed penetrating portions of sidewalls of the mold layer 102 protruding between the plurality of first trenches 104 . Each second trench 106 may penetrate into some portion of the sidewall of the m...

Embodiment approach 2

[0105] Figure 9 is a plan view showing a conductive pattern structure according to Exemplary Embodiment 2. FIG.

[0106] refer to Figure 9 , a mold layer 150 of insulating material may be formed on the substrate.

[0107] A plurality of first grooves 152 having a first width W1 may be formed at the mold layer 150 substantially parallel to each other along a first direction. Second trenches 154 may be formed penetrating portions of sidewalls of the mold layer 150 between the first trenches 152 . Each second groove 154 may penetrate the protruding mold layer 150 between two adjacent first grooves 152 . The second width W2 of the second trench 154 along the first direction may be the same as or smaller than the first width W1. The first groove 152 and the second groove 154 may have the same depth.

[0108] One or more third grooves 156 having a third width and disposed parallel to each other may be formed in the mold layer 150 .

[0109]The first width W1, the second widt...

Embodiment approach 3

[0127] Figure 13 is a plan view showing a conductive pattern structure according to Exemplary Embodiment 3. FIG. Figure 14 is a perspective view showing Figure 13 The conductive pattern structure shown.

[0128] refer to Figure 13 and Figure 14 , a mold layer 202 of insulating material may be formed on the substrate 200 . The mold layer 202 may have a stacked structure of a first silicon oxide layer 202a, an etch stop layer 202b, and a second silicon oxide layer 202c. In the mold layer 202, a contact hole 204 and trenches 206, 208, and 210 may be formed.

[0129] In particular, a contact hole 204 exposing a portion of the surface of the substrate 200 may be formed through the mold layer 202 . The contact holes 204 may be disposed along the first direction.

[0130] A first trench 206 connected to the contact hole 204 and extending in a first direction may be formed in a portion of the mold layer 202 including the contact hole 204 . The first trench 206 may have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com