Alkali metal doping treatment method for large-scale production of copper indium gallium selenide thin film solar cells

A solar cell, copper indium gallium selenide technology, applied in circuits, electrical components, photovoltaic power generation and other directions, can solve the problems of complex process flow, generation of hydrogen selenide, long return time, etc., to reduce the deposition thickness and the overall cadmium content. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

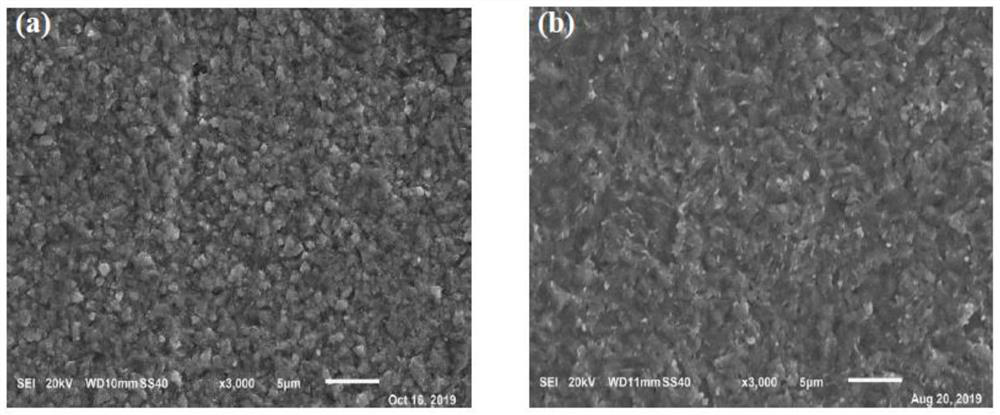

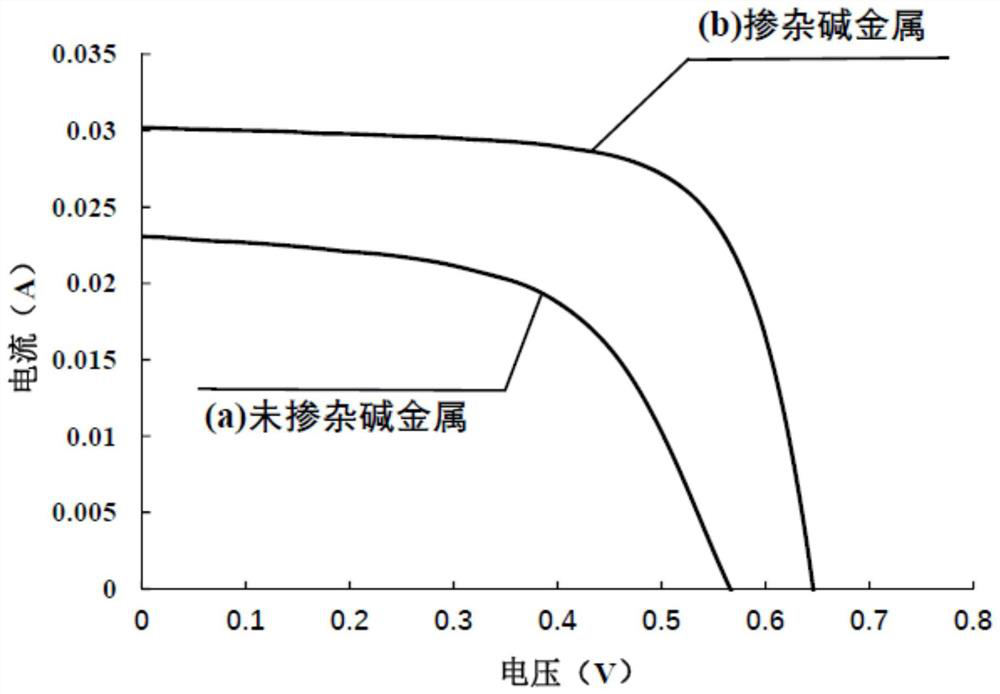

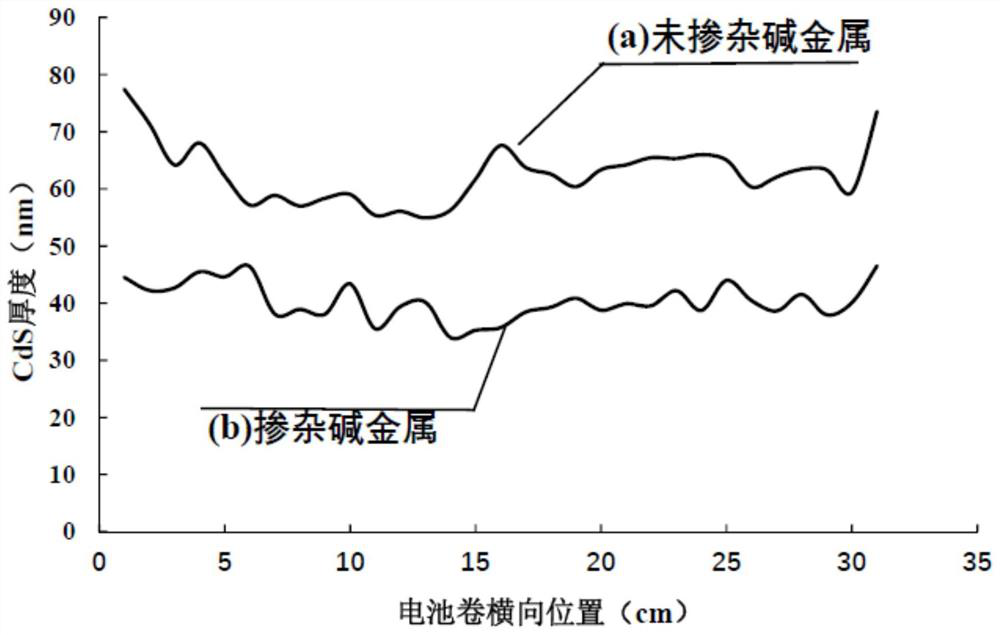

Image

Examples

Embodiment 1

[0058] A base metal doping treatment method when the copper indium gallium-producing film solar cell is largely produced, and the steps are as follows:

[0059] 1. A DC magnetron sputtering method is deposited on the substrate on the substrate on the substrate at a thickness of 25 μm flexible thin film substrate (stainless steel), deposits a layer of 0.4 μm thick Mo back electrode layer.

[0060] 2. Add 1700 g of silica gel desiccant as a water absorbing agent in the reaction device, in a vacuum is 1 × 10 -3 The substrate was heated to 150 ° C in the co-evaporation chamber of the PA, and a layer of NaF layer was evaporated on the surface of the Mo back electrode layer, and the NAF evaporation source temperature was 760-800 ° C, and the evaporation time was 10 min.

[0061] 3. The substrate temperature is increased to 480 ° C, circulate in, Ga, SE, where the in the evaporation source temperature is from 940 to 1050 ° C, the Ga evaporation source temperature is from 1050 to 1200 ° C...

Embodiment 2

[0072] A base metal doping treatment method when the copper indium gallium-producing film solar cell is largely produced, and the steps are as follows:

[0073] 1. A DC magnetron sputtering method is deposited on the substrate on the substrate in a thickness of 40 μm flexible thin film substrate (polyimide), deposits a layer of 0.8 μm thick Mo back electrode layer.

[0074] 2. Add 1800 g of anhydrocalized calcium chloride as a water absorbing agent in the reaction apparatus, at a vacuum is 3 × 10 -3 The substrate was heated to 300 ° C in the conjunction of the PA, and a layer of Naf layer was evaporated on the surface of the Mo back electrode layer, and the NAF evaporation source temperature was 760-800 ° C, and the evaporation time was 20 min.

[0075] 3. The substrate temperature is increased to 600 ° C, circulate in, Ga, SE, where the in evaporation source temperature is from 940 to 1050 ° C, Ga evaporation source temperature is 1050-1200 ° C, SE evaporation source temperature ...

Embodiment 3

[0086] A base metal doping treatment method when the copper indium gallium-producing film solar cell is largely produced, and the steps are as follows:

[0087] 1. A DC magnetron sputtering method is deposited on the substrate on the substrate at a thickness of 30 μm flexible film substrate (stainless steel) to deposit a layer of 0.6 μm thick Mo back electrode layer.

[0088] 2. Add 2000 g of silica gel desiccant as a water absorbing agent in the reaction device, 2 × 10 in vacuo -3 The substrate is heated to 200 ° C in the conjunction of the PA, and a layer of NaF layer is evaporated, and the NaF evaporation source temperature is 760-800 ° C, the evaporation time is 15 min.

[0089] 3. The substrate temperature is increased to 550 ° C, circulate in, Ga, SE, where the in the evaporation source temperature is from 940 to 1050 ° C, the Ga evaporation source temperature is from 1050 to 1200 ° C, the SE evaporation source temperature is 450-500 ° C, The evaporation time was 15 min.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com