A method for manufacturing ultra-thin and light-weight jump floor slabs

A manufacturing method and a technology of jumping floors, which are applied to floors, building structures, building materials, etc., can solve the problems of difficulty in meeting demand, reduce floor height, and low floor strength, and achieve simple installation, increased floor height, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

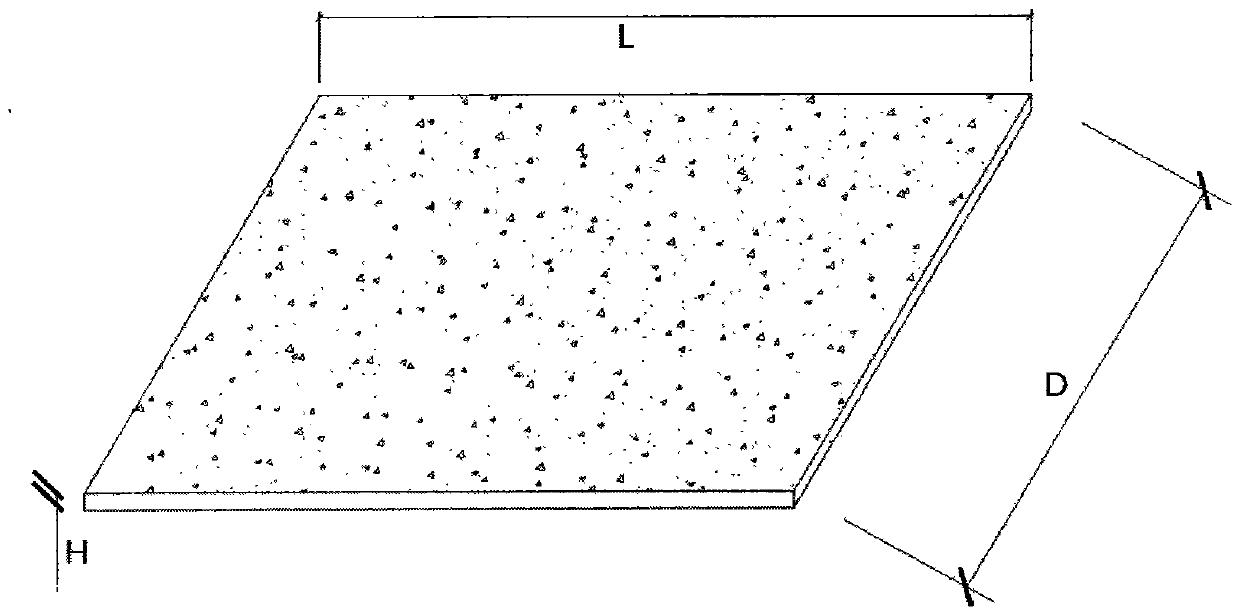

[0012] figure 1 A schematic diagram of a jump floor slab manufactured by the manufacturing method of the present invention is shown. Such as figure 1 As shown, preferably, the length of the longer side of the jump floor slab is L=1300mm; the length of the shorter side is D=770mm; and the thickness H=30mm.

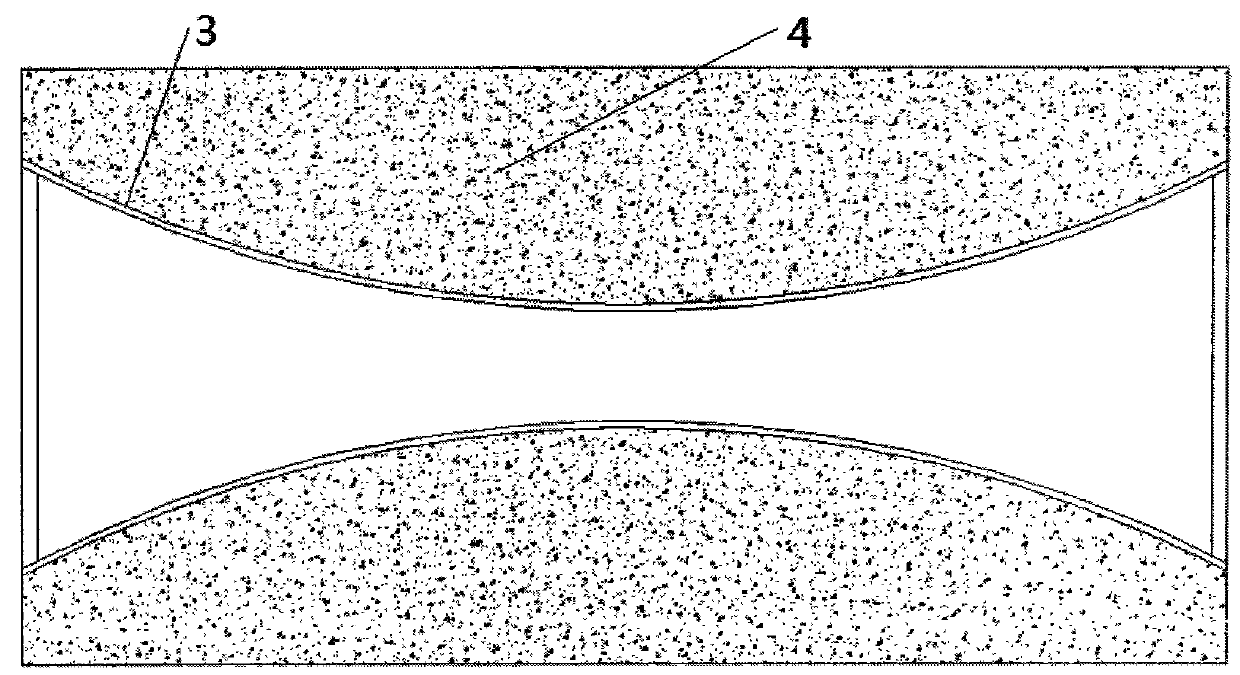

[0013] Combine below Figure 2-3 The manufacturing method of the jump floor slab of the present invention is specifically introduced.

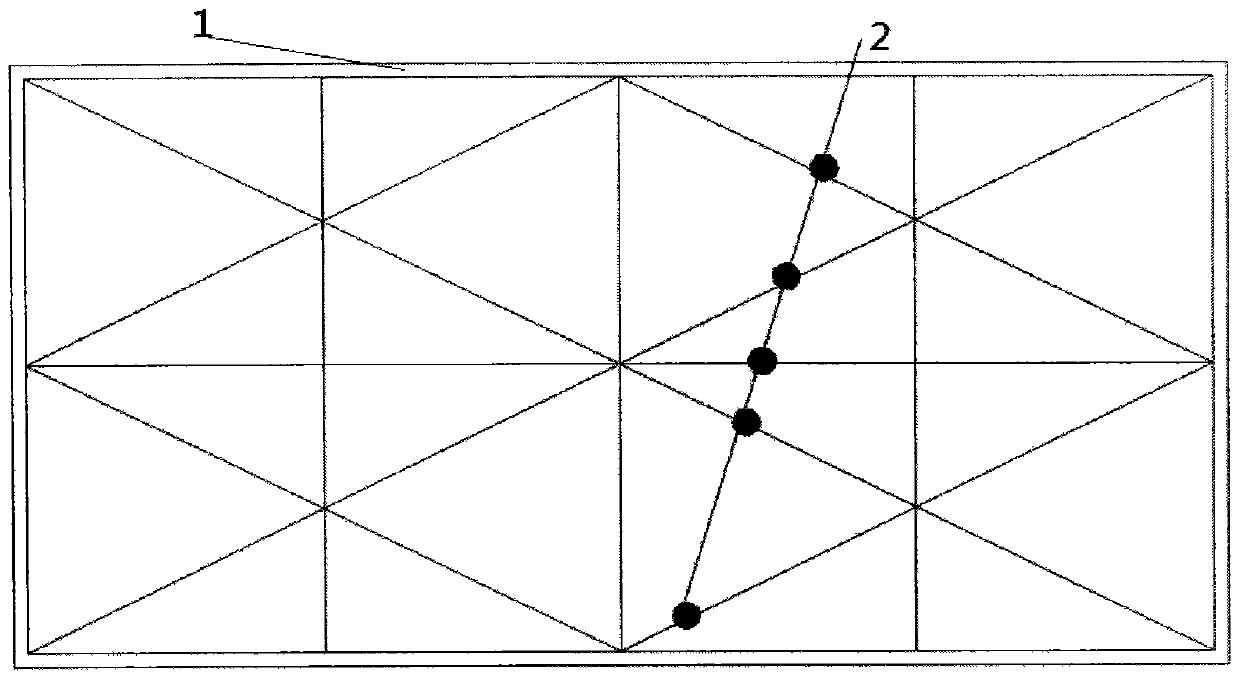

[0014] figure 2 A schematic diagram showing one of the bottom surfaces of the frame used in the manufacturing method of the present invention. Such as figure 2 Shown, when making the frame of this jump floor, at first by welding with angle steel to form outer frame 1, the size of this outer frame 1 has just determined the size of jump floor. After the outer frame 1 is welded, a steel grid 2 is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com