Weight measuring method of wheat in horizontal warehouse

A measuring method and technology of flat silo, which are applied in the direction of measuring device, weighing, weighing equipment for materials with special properties/forms, etc., which can solve the problem of large weight error of wheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 adopts the inventive method to measure wheat storage weight in the flat storehouse

[0064] Select the real warehouse provided by Nanjing Tiexinqiao National Grain Reserve to verify the accuracy of the method of the present invention. The method of measuring the weight of wheat is as follows:

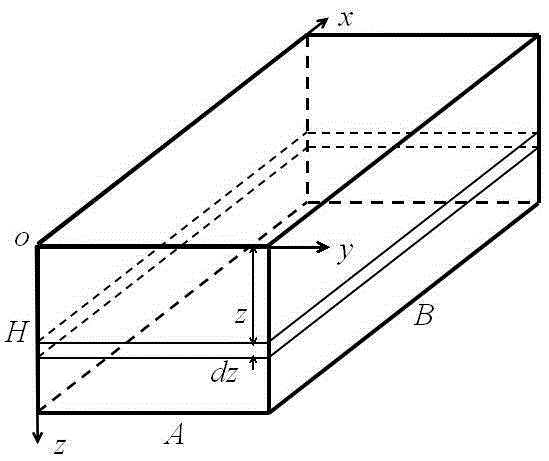

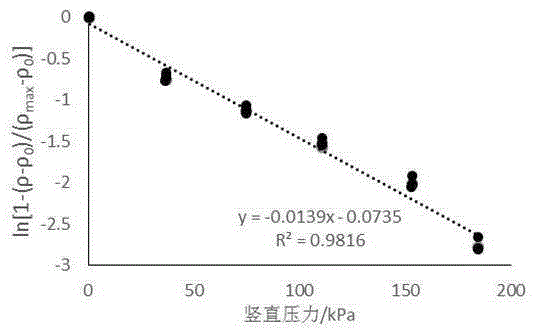

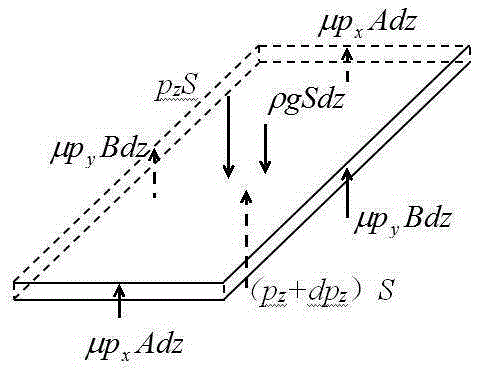

[0065] (1) The length B and width A of the flat warehouse, the friction coefficient μ between the wheat and the flat warehouse wall, and the internal friction angle of the wheat pile Other parameters are shown in Table 4. The height of the grain surface is exactly the height of the wheat pile. According to the conventional method, use a vernier caliper to measure the large particle size, medium particle size, and small particle size of wheat grains, and the average value is the equivalent particle size; the equivalent particle size is used as the wheat particle size. The three particle sizes of Ningmai No. 13 are 6.28, 3.40, and 2.90 mm, and the equivalent partic...

Embodiment 2

[0079] Embodiment 2 Measuring method of the present invention compares with bulk density method

[0080] Adopt volume density method to measure the wheat in each flat storehouse among the embodiment 1. The correction coefficient of the bulk density method is 1.02, and the calculation results are shown in Table 6:

[0081] Table 6 Comparison of errors between the measured value and the actual book value

[0082]

[0083] As can be seen from Table 6, the maximum error measured by the bulk density method is 4.40%, and the average error is 3.13%; the maximum error of the measurement method of the present invention is 2.62%, and the average error is 1.77%; the measurement method of the present invention has high precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com