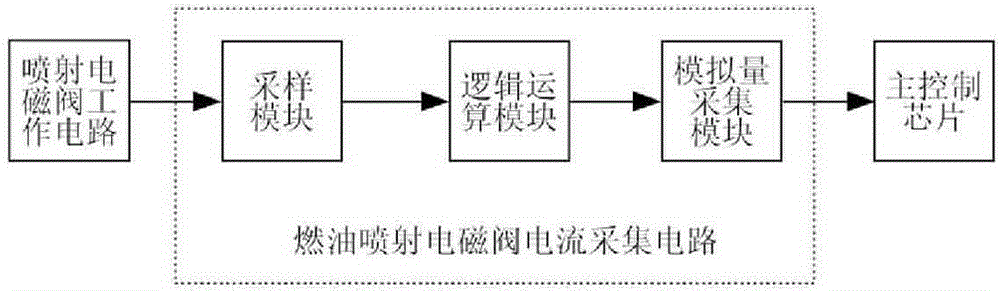

Current detection circuit of fuel oil injection solenoid valve

A current detection circuit and fuel injection technology, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problems of high cost and large installation volume, and achieve the effect of low price, small size and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

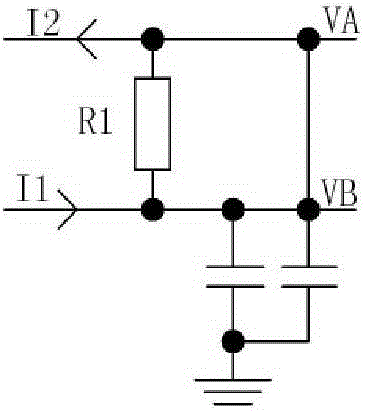

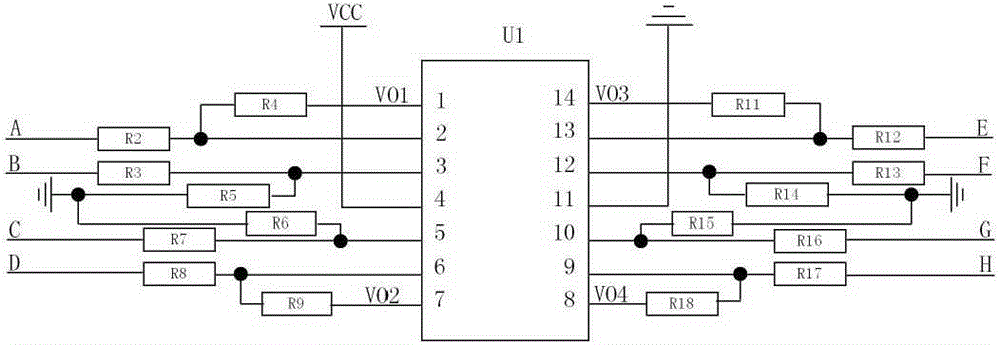

[0016] The specific circuit is attached figure 2 , 3 , 4 shown.

[0017] Sampling module of the present invention such as figure 2 , the circuit is mainly composed of sampling resistor R1, filter capacitors C1, C2 and their connections. The sampling resistor R1 is connected in series to the working circuit of the injection valve, the signal I1 is connected to the low drive output terminal, the signal I2 is connected to GND, and the capacitor One end of C1 is connected to the lower end of R1, and the other end is connected to GND; one end of capacitor C2 is connected to the upper end of R1, and the other end is connected to GND.

[0018] Logic operation module of the present invention such as image 3 , the circuit is mainly composed of an operational amplifier numbered U1, a resistor and its connection, where R4 is connected between the first pin and the second pin of U1, and R2 is connected between the signal A and the second pin of U1 Between, R3 is connected to signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com