Equivalent method for predicting thermo-mechanical fatigue life

A thermomechanical fatigue and life-span technology, applied in the field of fatigue strength, can solve problems such as ignoring engine damage, reliability uncertainty, etc., and achieve the effect of saving test cost and good prediction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

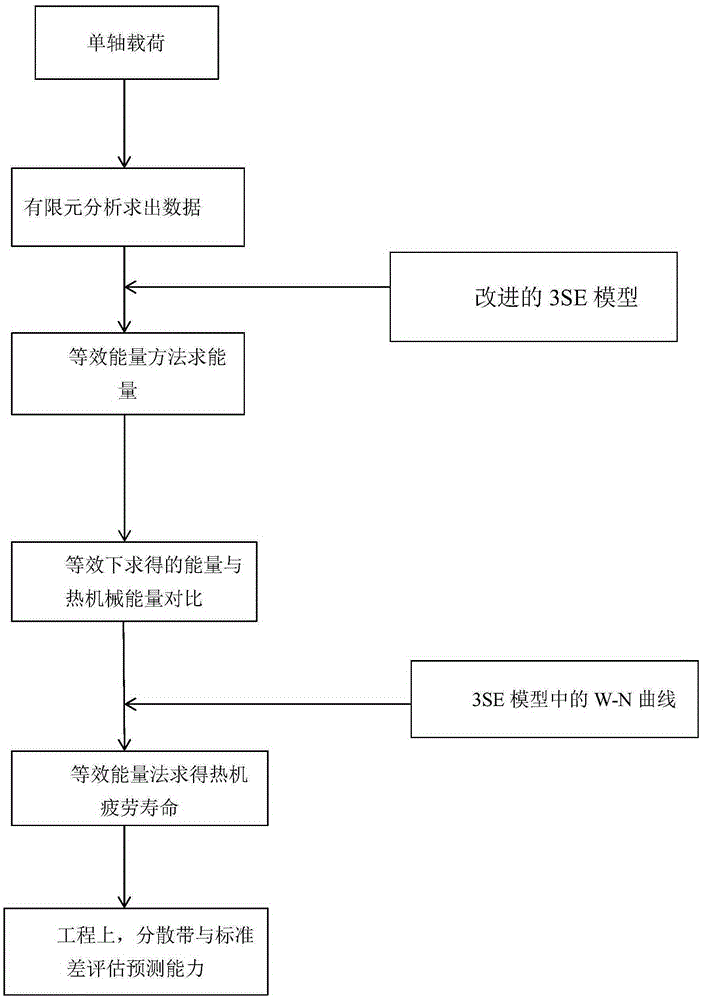

[0031] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

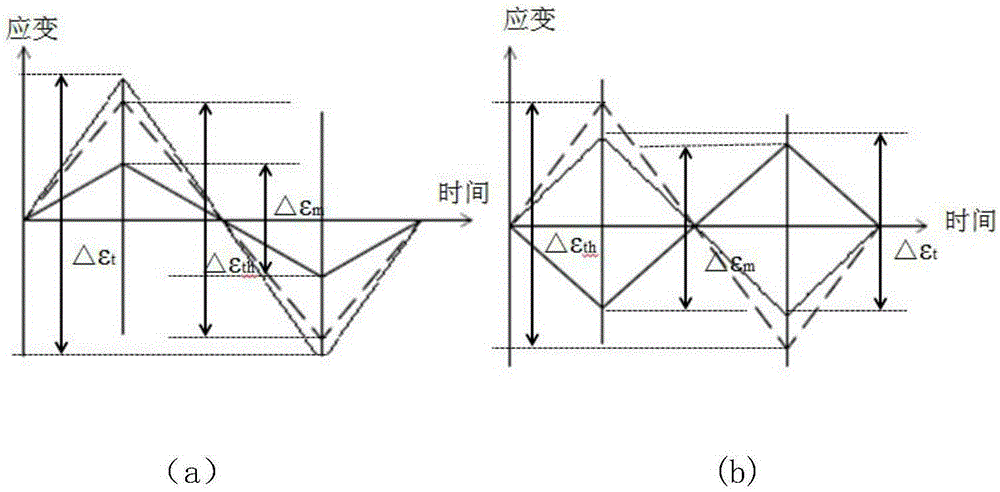

[0032] The present invention further illustrates the present invention through thermal-mechanical fatigue tests. The loading waveform of the test is a triangular waveform, the stress ratio is -1, and it is carried out under different control strains.

[0033] An equivalent method for predicting thermomechanical fatigue life, the specific implementation is as follows:

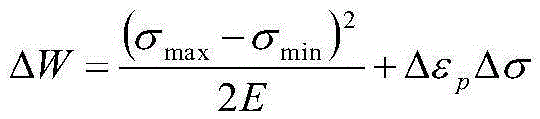

[0034] Step 1): Use the finite element method to calculate the high temperature fatigue data at the highest temperature and the thermal strain data at the corresponding temperature range; when using the finite element method to solve the high temperature fatigue data, the control strain conversion displacement formula used for:

[0035] dϵ Z = d l l

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com