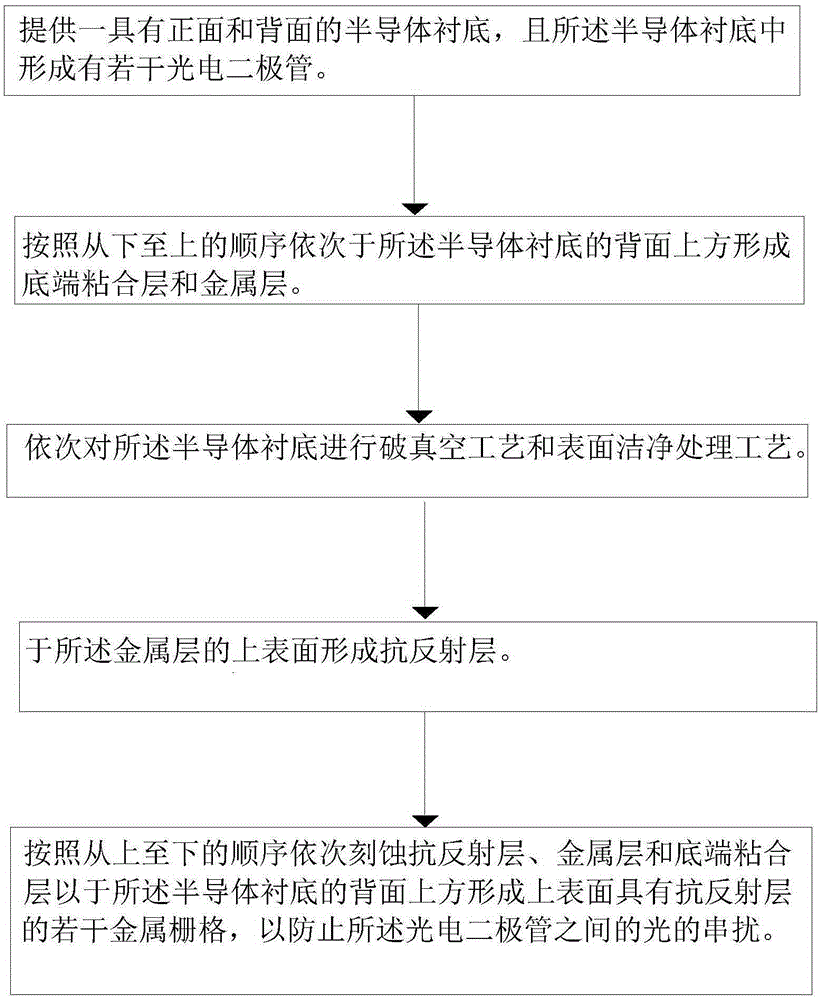

Method for preparing backside-illuminated sensor

A sensor and back-illuminated technology, which is applied in the field of back-illuminated sensor preparation, can solve problems affecting the performance of back-illuminated sensor chips, crosstalk, and abnormal protrusions formed on the metal grid layer, so as to avoid abnormal protrusions and reduce abnormalities. Growth, avoiding the effect of light crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as figure 1 As shown, this embodiment relates to a method for preparing a back-illuminated sensor, which may be a back-illuminated image sensor. Specifically, the method includes the following steps:

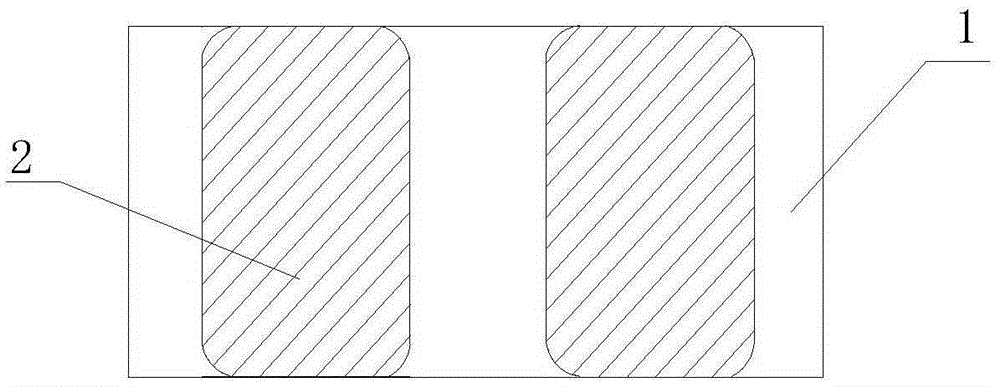

[0028] Step 1, providing a semiconductor substrate 1 with a front and a back surface, and a photodiode array (pixel array) formed by several photodiodes 2 (pixels) is formed in the semiconductor substrate 1; in an embodiment of the present invention, the Semiconductor substrate 1 is the wafer that has finished the previous layer process; figure 2 structure shown.

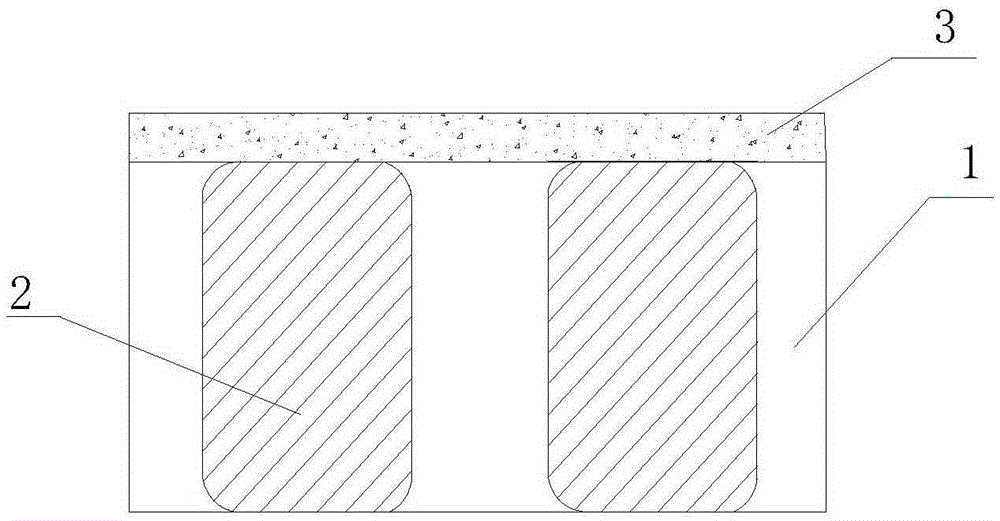

[0029] Step 2, forming a bottom adhesive layer 3 on the back surface of the semiconductor substrate 1; Ion sputtering machine is formed by physical ion sputtering. Preferably, the material of the bottom bonding layer 3 is titanium nitride; as image 3 structure shown.

[0030] Step 3, forming a metal layer 4 on the upper surface of the bottom adhesive layer 3; in an embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com