Flexible thin film transistor and its manufacturing method

A flexible thin film and manufacturing method technology, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increasing the protection ability of the insulating layer and reducing the damage of the inorganic insulating layer, so as to avoid abnormal conduction and improve short circuit Problems, Effects of Enhanced Protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

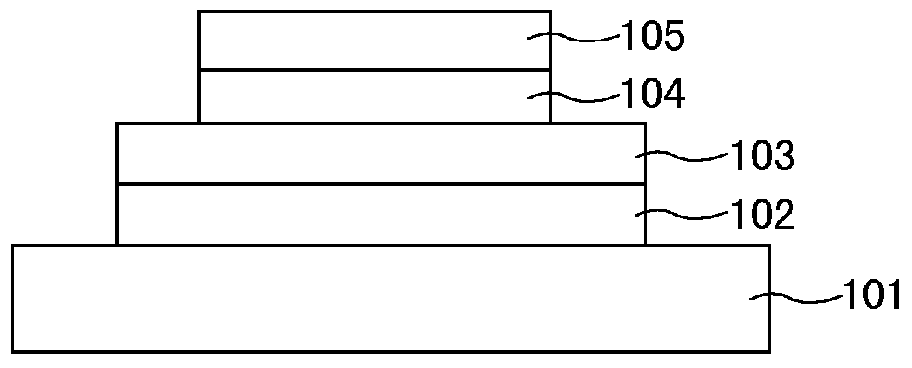

[0058] figure 1 It is a structural schematic diagram of the flexible thin film transistor of the present invention, such as figure 1 As shown, the flexible thin film transistor includes: a flexible substrate 101; a gate 102 disposed on the flexible substrate 101; an inorganic insulating layer 103 disposed on the gate 102; an organic conductive layer 104 disposed on the inorganic insulating layer 103 and a source / drain electrode 105 disposed on the organic conductive layer 104 . However, the flexible thin film transistor of the present invention is not limited to the above structure, and may include other layers of known thin film transistors such as active semiconducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com