Permanent magnet synchronous direct-drive motor

A technology of direct drive motor and permanent magnet synchronization, which is applied in the direction of suppressing electromagnetic interference, static parts of magnetic circuit, rotating parts of magnetic circuit, etc., can solve problems such as increased demagnetization inflection point, poor heat dissipation conditions, etc., and can reduce short-circuit current , improve the operating point, reduce the effect of rotor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

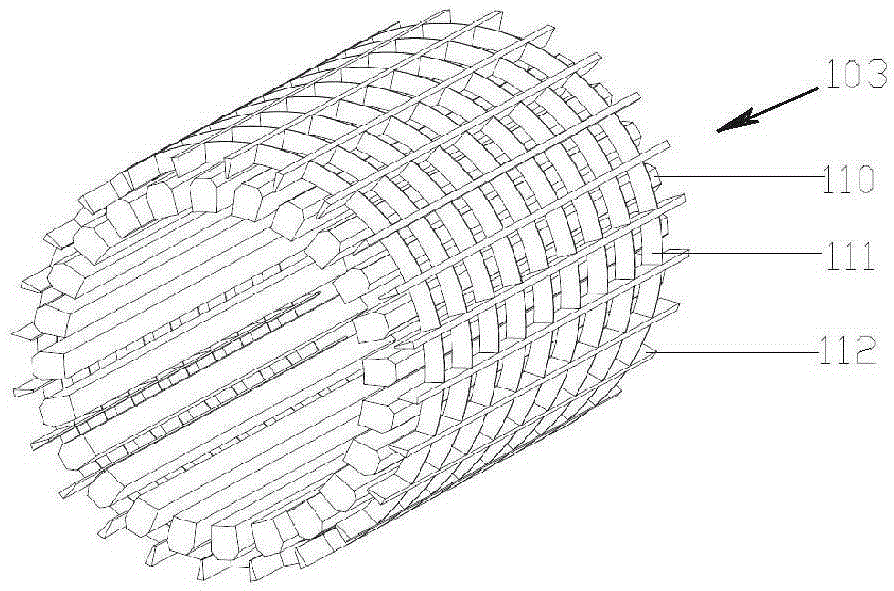

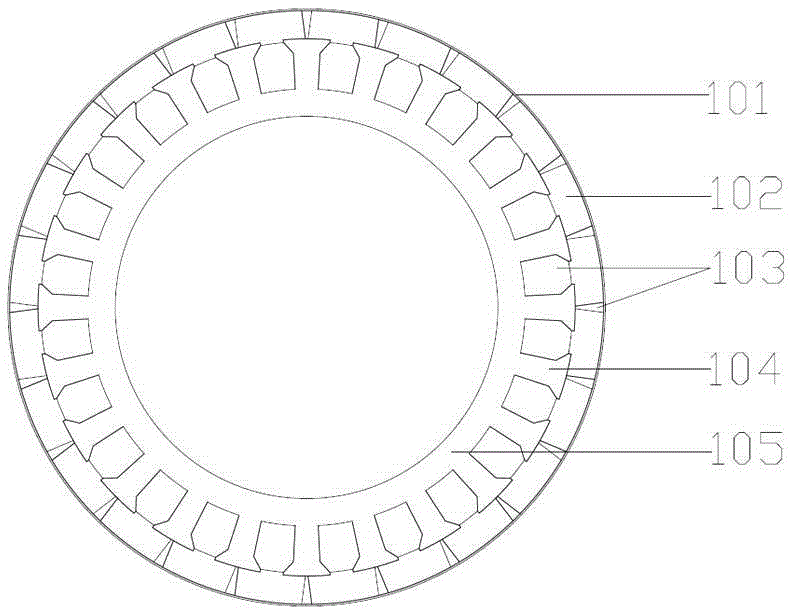

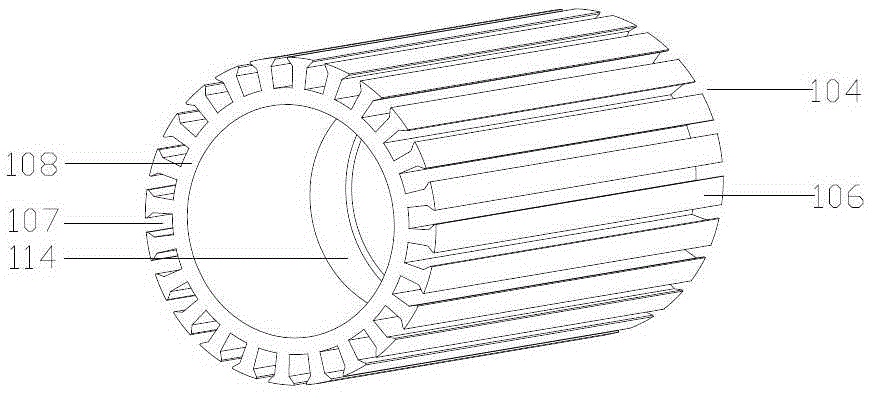

[0022] Below, refer to Figure 1 to Figure 8 , the present invention will be described in further detail.

[0023] figure 1 It is a radial sectional view of a rotor of a permanent magnet synchronous direct drive motor of the present invention. Such as figure 1 As shown, the rotor includes: a glass ribbon 101 , a permanent magnet 102 , a rotor core 104 , and a shaft 105 . On the shaft 105, the rotor core 104 and one side of the non-magnetic metal end plate 113 (such as Figure 5 , 6 shown). A number of semi-closed slots 107 are uniformly formed along the outer circumferential surface of the rotor core, and the semi-closed slots are parallel to the shaft 105 . A permanent magnet 102 is mounted on the outer circumference of the rotor core 104 , and the contact surface between the permanent magnet 102 and the rotor core 104 is bonded with glue. Epoxy resin 103 is potted in the gaps between the permanent magnets and in the semi-closed slots. After the epoxy resin is filled,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com