Welding device, welding system, program used in welding device, and control method of welding device

A welding device and welding condition technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as inability to confirm welding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

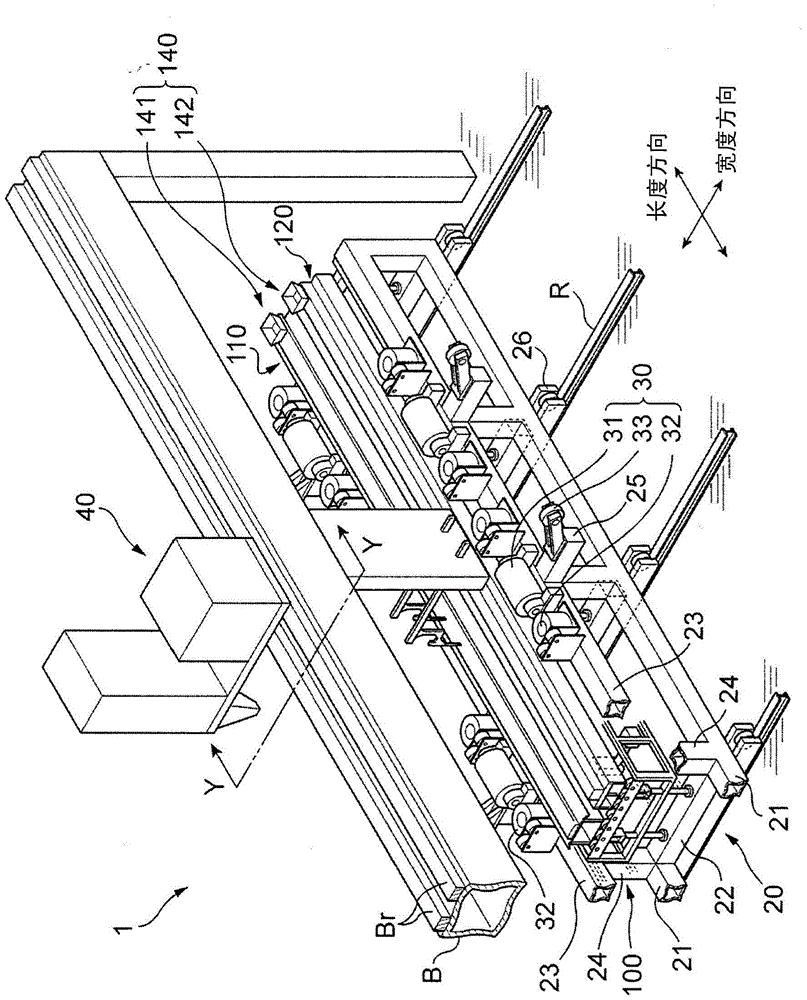

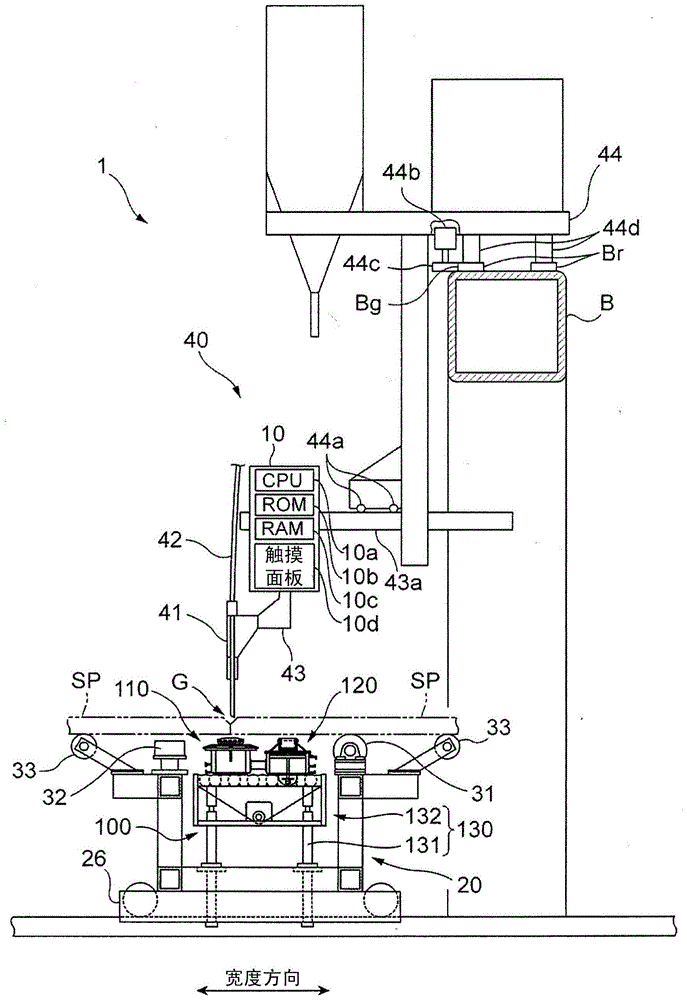

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. First, the outline of this embodiment will be described.

[0033]Generally, for example, in welding devices such as submerged arc welding devices and single-sided welding devices, two or more welding devices may be automatically operated at the same time. In this case, for example, the welding device can automatically detect the end portion of the steel plate to be welded, and stop the operation when the end portion is detected as the end of the welding operation. For this reason, as soon as the operator starts the welding work, the plurality of welding devices can automatically perform the welding work to the end.

[0034] However, along with the welding operation, the shape of the groove between the steel plates to be welded may change. In this case, if the welding conditions such as welding current and welding voltage during welding are not changed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com