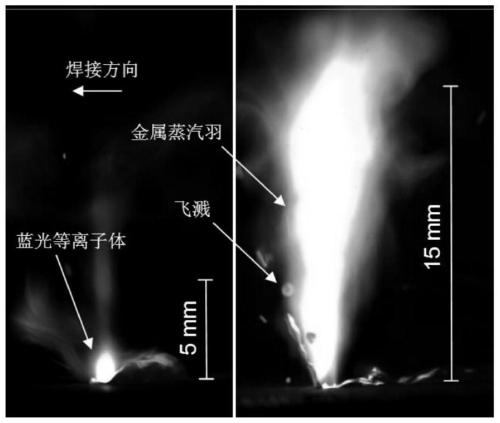

Method for suppressing generation of metal steam and photoinduced plasma

A plasma and metal vapor technology, used in metal processing equipment, manufacturing tools, laser welding equipment, etc., to achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

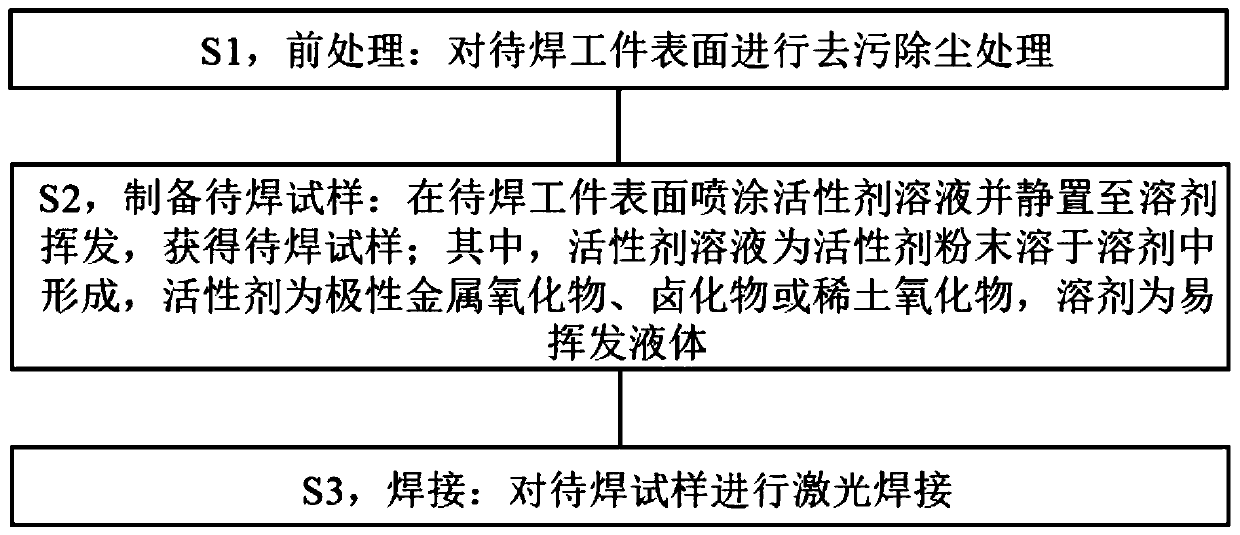

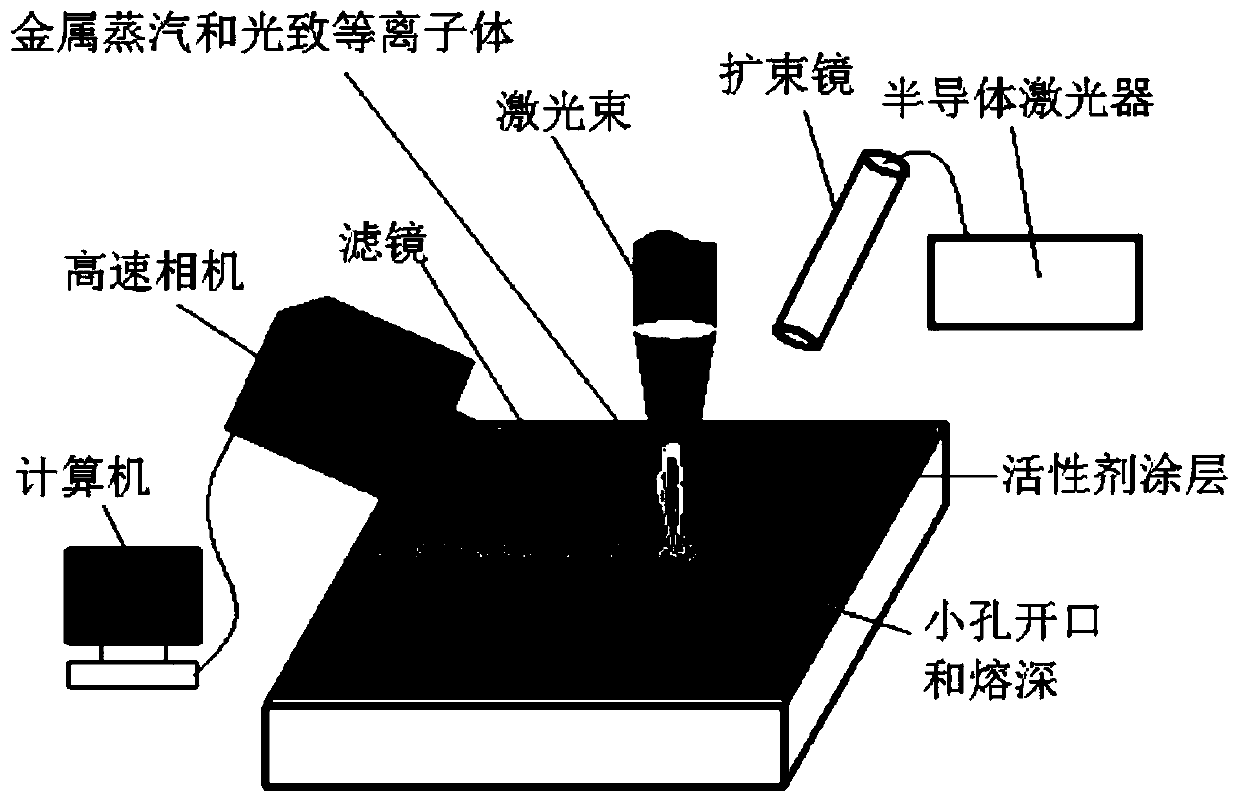

[0040] refer to figure 2 As shown, the embodiment of the present invention provides a method for suppressing the generation of metal vapor and photoinduced plasma, carried out in the laser welding test system, including the following steps:

[0041] S1, pretreatment: decontamination and dust removal on the surface of the workpiece to be welded.

[0042] In this embodiment, in order to remove stains and dust and ensure welding quality, it is necessary to perform surface treatment on the workpiece to be welded during laser welding. Optionally, the surface of the workpiece to be welded can be wiped with volatile solvents such as acetone and ethanol to remove oil-immersed dust; the workpiece to be welded can also be pickled, washed with water, etc. to remove impurities on the surface of the workpiece to be welded and then dried. Invention is not limited.

[0043] Further, in a preferred embodiment of the present invention, in this step, the step of decontaminating and dust-remo...

Embodiment 1

[0061] see Figure 5 As shown, prepare 100×50×8mm stainless steel as the workpiece to be welded, and wipe the surface of the workpiece to be welded with acetone to remove oil immersion dust.

[0062] Weighing Cr with precision electronic scale 2 o 3 Active agent, measure the acetone solution with a measuring cup, and add Cr 2 o 3 The active agent is dissolved in acetone solution to prepare a supersaturated solution. Put the above supersaturated solution into the coating cup of the micro-spray gun, start the air compressor, adjust the gas flow, control the spraying distance and spraying range, spray the active agent solution evenly on the surface of the workpiece to be welded by the micro-spray gun, and the spraying is completed Finally, let the workpiece to be welded stand until the acetone is completely volatilized to make a sample to be welded. Among them, the spraying amount is controlled at 0.05-0.1g / cm 2 .

[0063] After the sample is clamped, a fiber laser is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com