Traceless povidone iodine disinfectant

A technology of povidone iodine and disinfectant, which is applied in the field of non-trace povidone iodine disinfectant, which can solve the problems of cumbersome operation, increased cost, and reduced operating room utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

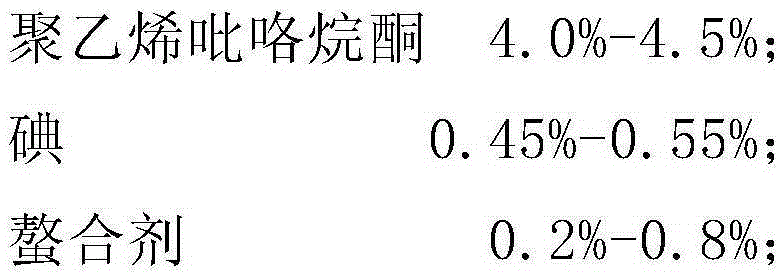

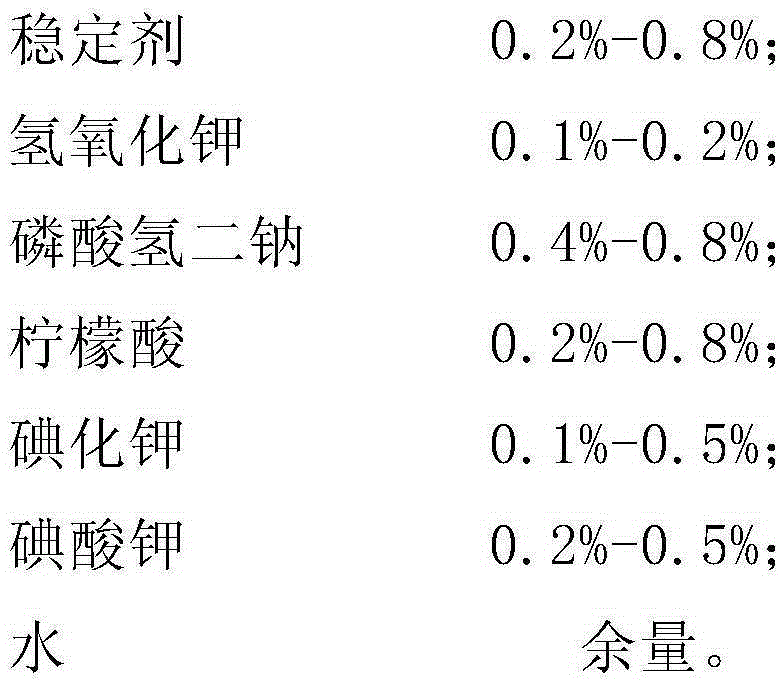

[0021] Non-trace povidone-iodine disinfectant, prepared from the following raw materials by weight percentage: polyvinylpyrrolidone 4.5%, iodine 0.5%, EDTA-2Na 0.1%, nonylphenol polyoxyethylene ether 0.3%, potassium hydroxide 0.1 %, disodium hydrogen phosphate 0.5%, citric acid 0.3%, potassium iodide 0.1%, potassium iodate 0.2%, and the rest is water.

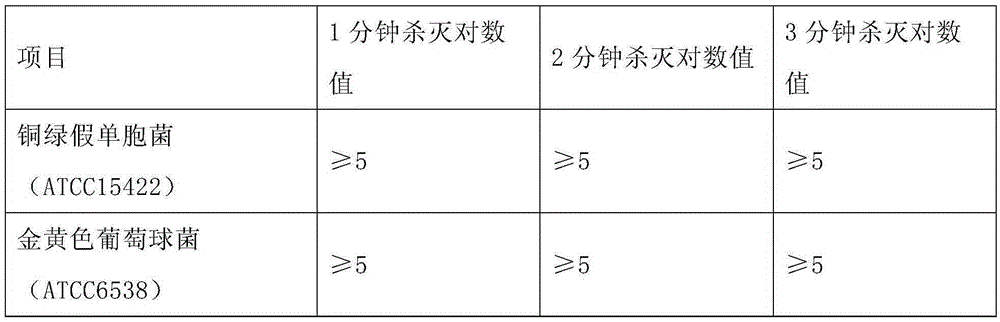

[0022] The bactericidal effect of the non-trace type povidone-iodine disinfectant of this embodiment is shown in Table 2

[0023] Table 2

[0024]

Embodiment 2

[0026] Non-trace povidone-iodine disinfectant, prepared from the following raw materials by weight percentage: polyvinylpyrrolidone 4.5%, iodine 0.47%, EDTA-4Na 0.3%, alkylphenol polyoxyethylene ether 0.5%, potassium hydroxide 0.2 %, disodium hydrogen phosphate 0.7%, citric acid 0.5%, potassium iodide 0.2%, potassium iodate 0.3%, and the rest is water.

[0027] The bactericidal effect of the non-trace type povidone-iodine disinfectant of this embodiment is shown in Table 3

[0028] table 3

[0029]

Embodiment 3

[0031] Non-trace povidone iodine disinfectant, prepared from the following raw materials by weight percentage: polyvinylpyrrolidone 5.0%, iodine 0.5%, PVP-K300.6%, glycerin 0.1%, potassium hydroxide 0.2%, disodium hydrogen phosphate 0.6%, citric acid 0.45%, potassium iodide 0.3%, potassium iodate 0.4%, and the rest is water.

[0032] The bactericidal effect of the non-trace type povidone-iodine disinfectant of this embodiment is shown in Table 4

[0033] Table 4

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com