Photocuring 3D printer and working method thereof

A 3D printer and working method technology, applied in the direction of additive processing, etc., can solve the problems of large volume, unfavorable large-scale promotion, high manufacturing cost, etc., and achieve the effect of small size, conducive to large-scale promotion, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

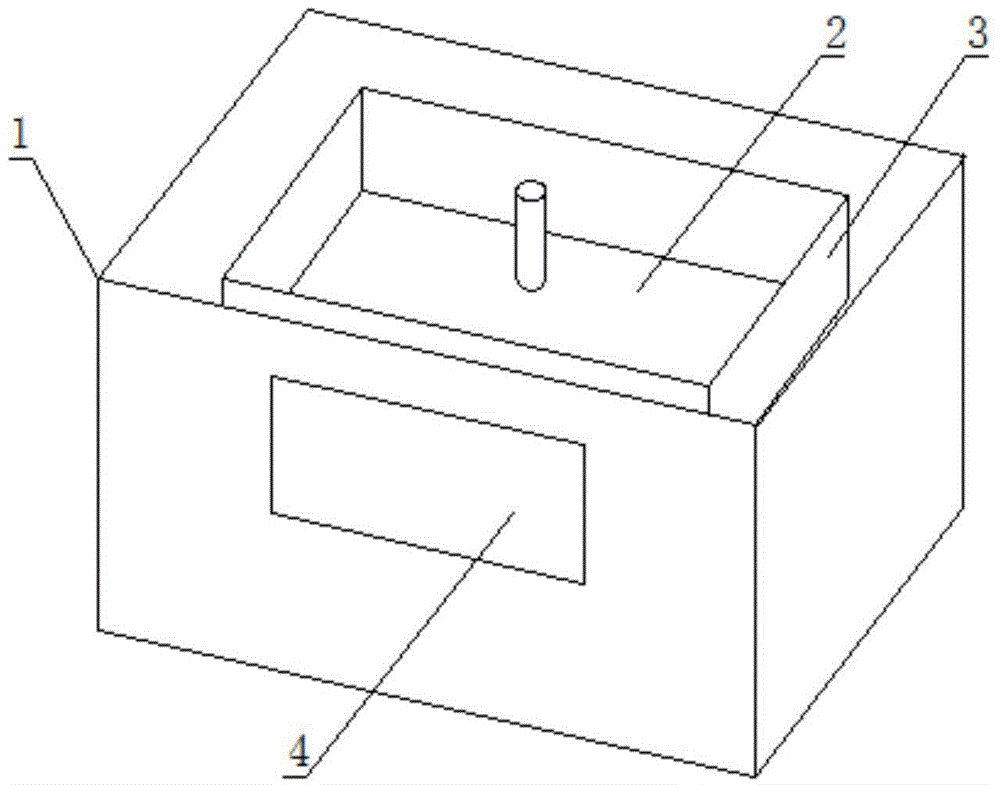

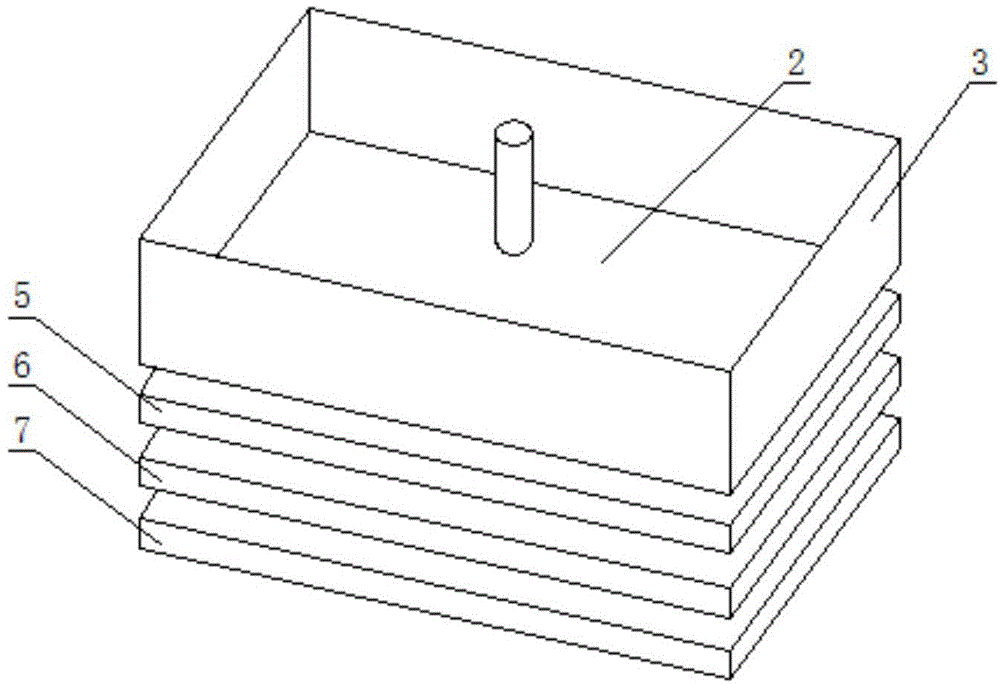

[0018] Such as Figure 1-2 As shown, a light-curing 3D printer includes a body 1, a printing material tank 3 and a printing platform 2 are arranged in the body 1, and a control panel 4 for controlling digital control of the digital channel of ultraviolet rays by a digital program is also arranged in the body 1, The lower part of the printing tank 3 is provided with a control board 5, and the lower part of the control board 5 is provided with a light source board 7, on which an ultraviolet light source is arranged in an array, and an oxygen-permeable film is provided at the bottom of the inner surface of the printing tank 3.

[0019] A working method of a light-curing 3D printer. When an ultraviolet light source is irradiated, the digital channel of the ultraviolet light is digitally controlled through the digital program in the control panel 4, so that the required image is projected according to the digital program control, and the encoded image is irradiated to the printer. ...

Embodiment 2

[0021] Such as Figure 1-2 As shown, a light-curing 3D printer includes a body 1, a printing material tank 3 and a printing platform 2 are arranged in the body 1, and a control panel 4 for digitally controlling the digital channel of ultraviolet rays by a digital program is also arranged in the body 1, The control panel 4 is an LCD liquid crystal control panel, a control panel 5 is provided at the bottom of the printing tank 3, a scattering panel 6 is provided at the bottom of the control panel 5, and a light source board 7 is provided below the diffusion panel 6, and the light source board 7 is arrayed. Ultraviolet light sources are arranged, and an oxygen-permeable film is arranged on the bottom of the inner surface of the printing tank 3 .

[0022] A working method of a light-curing 3D printer. When an ultraviolet light source is irradiated, the digital channel of the ultraviolet light is digitally controlled through the digital program in the control panel 4, so that the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com