Motor vehicle door installation harness

A technology for motor vehicle doors and fittings, which is applied in the field of body manufacturing and assembly, can solve the problems of time-consuming and labor-intensive handling of vehicle doors, limited application scope of door fittings, etc., and achieves the effects of low maintenance cost, saving rework time, and strong reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

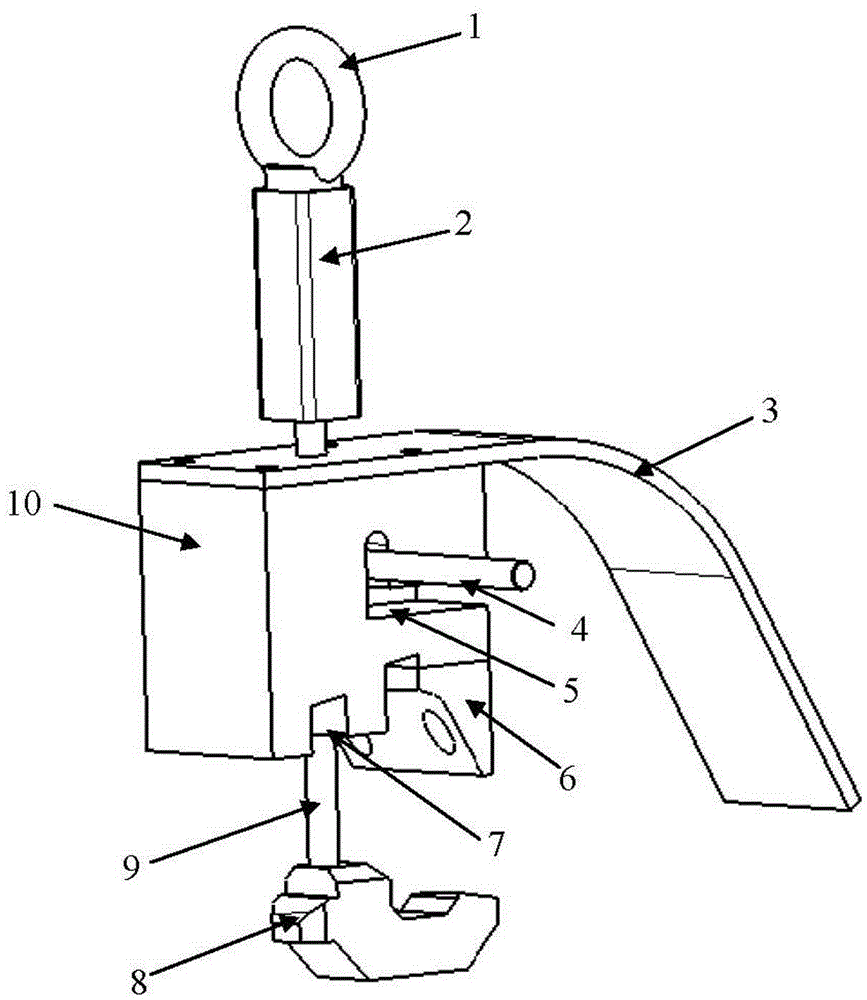

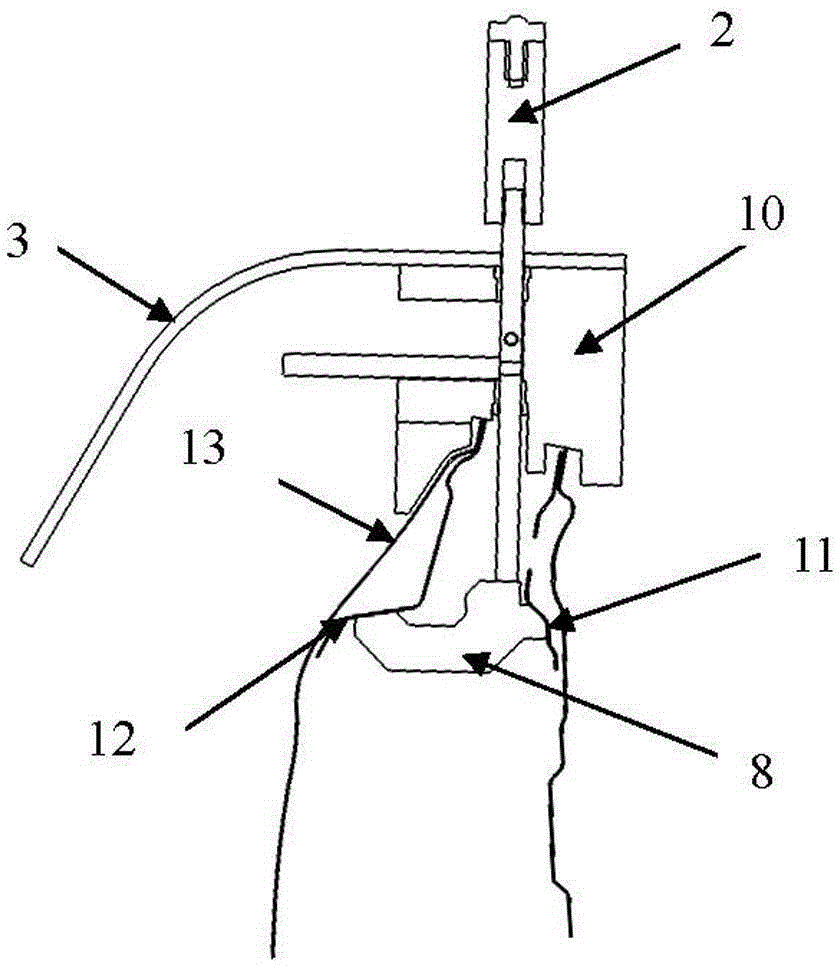

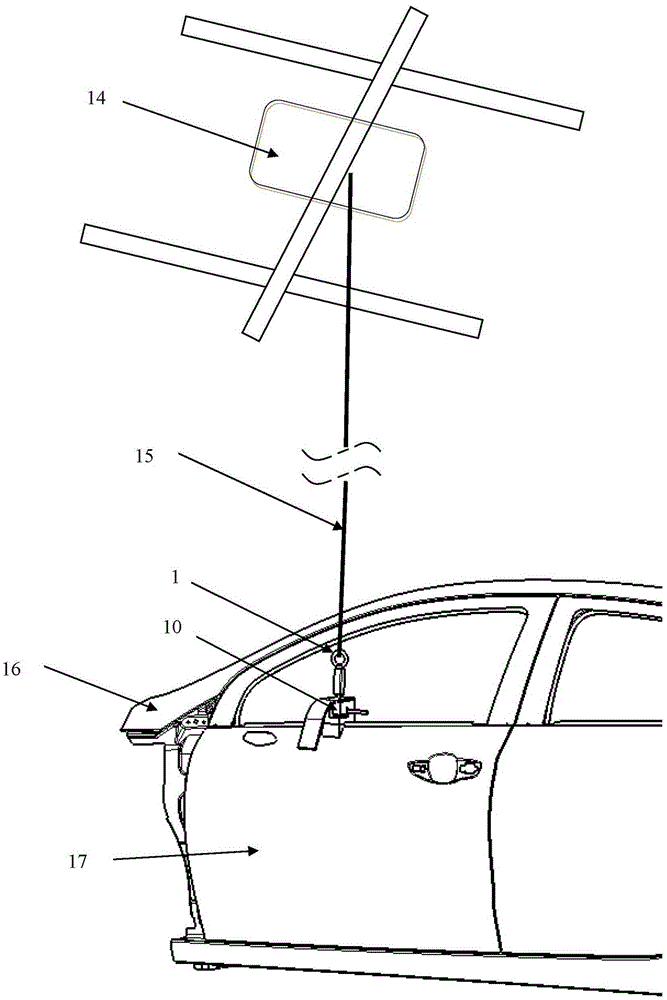

[0016] Depend on Figure 1-3 As shown, the example takes the application of the present invention in small cars as an example.

[0017] 10 in the figure is the fitting guide body, on which a connecting rotating shaft 9 is installed vertically on the fitting guiding body 10, and a fitting connecting ring 1 is fixedly connected to the upper part of the connecting rotating shaft 9 through the fitting connecting rod 2, and connected to the rotating shaft 9 The lower part of the device is fixedly provided with a device inner plate support block 8; a device operating handle 4 is arranged horizontally on the device guide body 10, and the other end of the device operating handle 4 is threadedly connected with the connecting rotating shaft 9 through the device body guide groove 5; The lower part of the main body 10 is also fixed with a polyurethane profile limiting block 6 .

[0018] On the upper plane of the guide body 10 of the equipment, there is also an auxiliary arc-shaped handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com