Organic fertilizer and preparation method thereof

An organic fertilizer and fertilizer technology, applied in the field of organic fertilizer and its preparation, can solve the problems of low yield, no or insufficient harvest, unreasonable fertilization, etc., and achieve the effects of promoting plant growth and prolonging fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

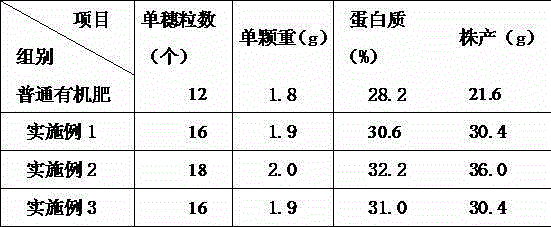

Examples

Embodiment 1

[0026] An organic fertilizer and a preparation method thereof, comprising the steps of:

[0027] 1) Take 4,000 parts of kitchen waste and grind and squeeze them through the garbage treatment device to obtain dehydrated garbage materials. Take 3,000 parts of plant straw and put them into the shredder, and crush the plant straw through the shredder for later use;

[0028] 2) Take 2000 parts of crushed soil, 1000 parts of egg shells, 500 parts of cow dung and 600 parts of medicine dregs and pour them into the organic fertilizer manufacturing pool, and add the materials processed in step 1) and mix them evenly with the above materials, and set aside;

[0029] 3) Take 500 parts of earthworms and put them into the organic fertilizer manufacturing pool where the materials have been processed in step 2), and build a scaffold to keep out the sun and rain, and reserve them;

[0030] 4) Take 2000 parts of straw, soak the straw in water for 7 hours, then take out the straw and cover it on...

Embodiment 2

[0040] An organic fertilizer and a preparation method thereof, comprising the steps of:

[0041] 1) Take 6,000 parts of kitchen waste and grind and squeeze them through a garbage treatment device to obtain dehydrated garbage materials. Take 4,500 parts of plant straw and put them into a shredder, and crush the plant straw through the shredder for later use;

[0042] 2) Take 3000 parts of crushed soil, 1600 parts of egg shells, 1000 parts of cow dung and 900 parts of medicine dregs and pour them into the organic fertilizer manufacturing pool, and add the materials processed in step 1) and mix them evenly with the above materials, and set aside;

[0043] 3) Take 700 parts of earthworms and put them into the organic fertilizer manufacturing pool where the materials have been processed in step 2), and build a scaffold to keep out the sun and rain, and reserve them;

[0044] 4) Take 2500 parts of straw, soak the straw in water for 7 hours, then take out the straw and cover it on th...

Embodiment 3

[0054] An organic fertilizer and a preparation method thereof, comprising the steps of:

[0055] 1) Take 8,000 parts of kitchen waste and grind and squeeze them through a garbage disposal device to obtain dehydrated garbage materials. Take 6,000 parts of plant straw and put them into a shredder, and crush the plant straw through the shredder for use;

[0056] 2) Take 4000 parts of crushed soil, 2300 parts of egg shells, 1500 parts of cow dung and 1200 parts of medicine dregs and pour them into the organic fertilizer manufacturing pool, and add the materials processed in step 1) and mix them evenly with the above materials, and set aside;

[0057] 3) Take 1,000 parts of earthworms and put them into the organic fertilizer manufacturing pool where the materials have been processed in step 2), and build a scaffold to keep out the sun and rain, and reserve them;

[0058] 4) Take 3000 parts of straw, soak the straw in water for 7 hours, then take out the straw and cover it on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com