Modified asphalt with high elastic resilience and preparing method thereof

A technology of modified asphalt and a manufacturing method, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of poor toughness, short service life of roads, poor low temperature resistance, etc., and achieves excellent deformation recovery ability, excellent Good self-healing ability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

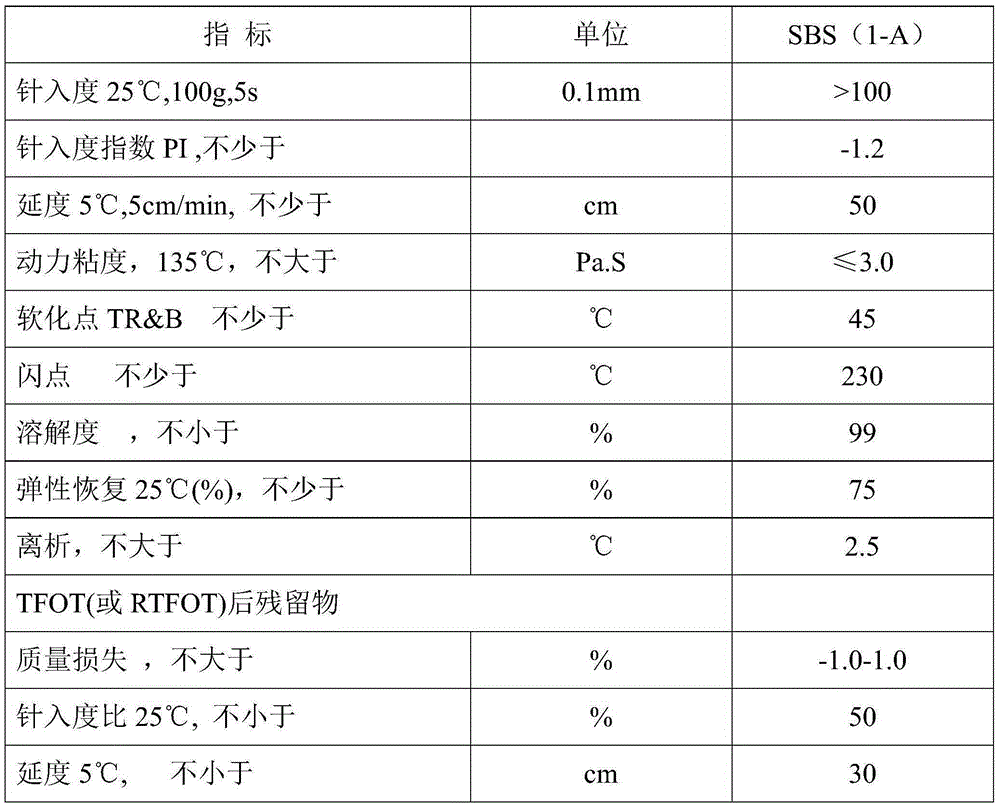

[0026] A modified asphalt with high resilience described in the present invention comprises raw materials: Venezuelan crude oil matrix asphalt, catalytic oil slurry desolidified oil, Venezuelan crude oil heavy component oil, modifier and crosslinking agent, and the modifier includes styrene- Butadiene-styrene block copolymer, the crosslinking agent is methyl orthosilicate and titanium acetylacetonate.

[0027] The weight ratio of Venezuelan crude oil base bitumen, catalytic oil slurry desolidified oil, Venezuelan crude oil, modifier and crosslinking agent is: 65%: 18%: 12%: 3%: 2%. At the same time, modified Graphene with 2% weight of permanent asphalt makes the asphalt have excellent comprehensive performance and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com