Friction damper for ancient timber structure tenon-mortise joints

A friction damper, ancient building wood technology, applied in building components, building structures, buildings, etc., to achieve the effect of convenient maintenance and replacement, improve energy consumption capacity, and reduce the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The application will be described in detail below with reference to the drawings and embodiments.

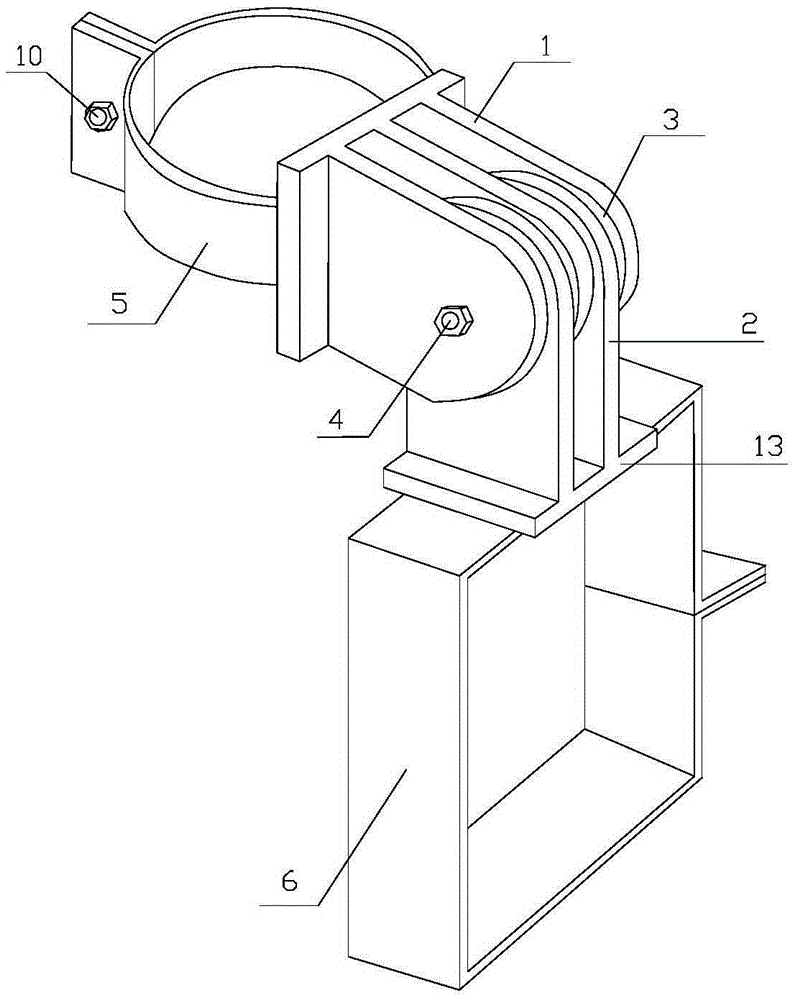

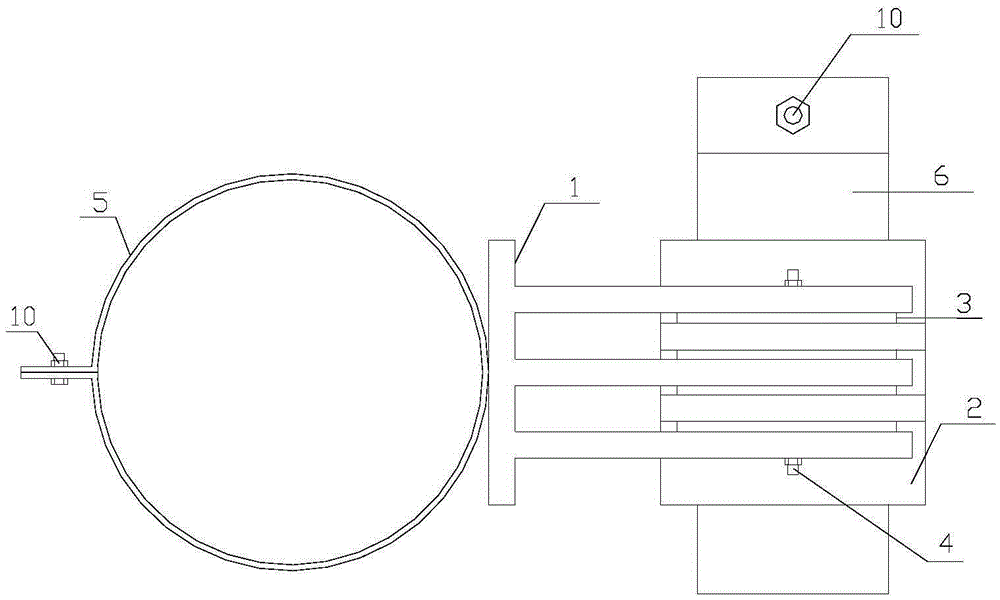

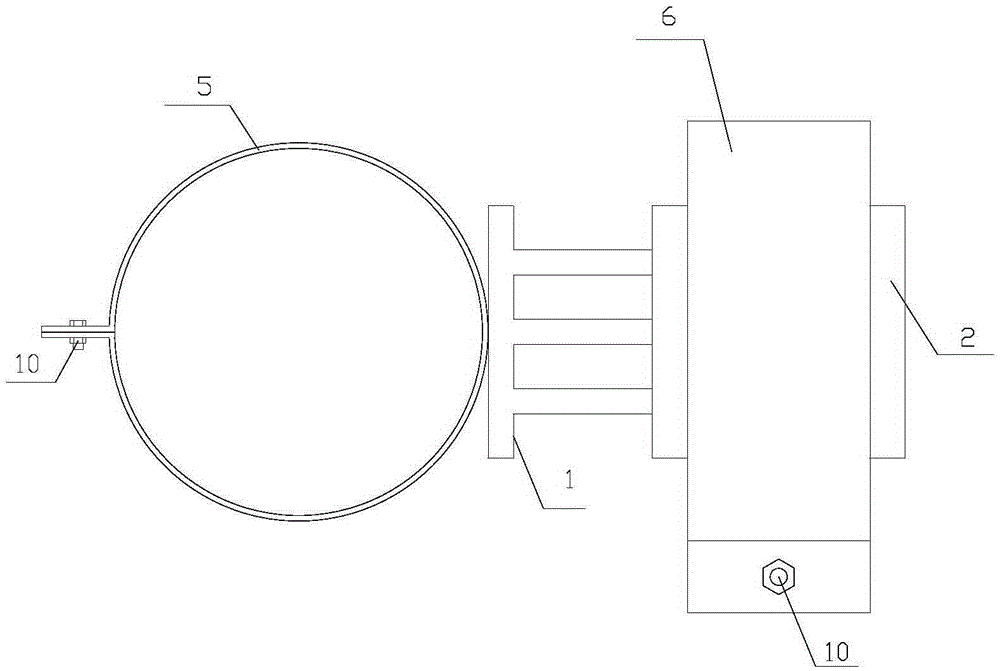

[0036] In this embodiment, the relative rotation between the steel plates is used to realize the function of helping the frictional energy consumption of the tenon-and-mortise joint. Such as figure 1 As shown, the ancient-built wooden frame tenon-and-mortise joint friction damper includes a first steel plate part connected with a column 1, a second steel plate part connected with a beam 2, a friction plate between the plates 3, bolts and washers 4, used for the first steel plate The first hoop 5 for connecting the part 1 and the column, and the second hoop 6 for connecting the second steel plate part 2 and the beam. The first steel plate portion 1 includes a first substrate 8 and three perforated connecting pieces 9 fixedly connected to the plane of the substrate. The three perforated connecting pieces are spaced apart and parallel to each other; the second steel plate porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com